Overturning dumping device and system for tar residues

A technology of dumping device and tar residue, which is applied in the field of tar residue dumping device and system, can solve the problems of increased manual processing cost, incomplete dumping, environmental pollution, etc., achieves simple structure, avoids leakage pollution, and meets production needs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

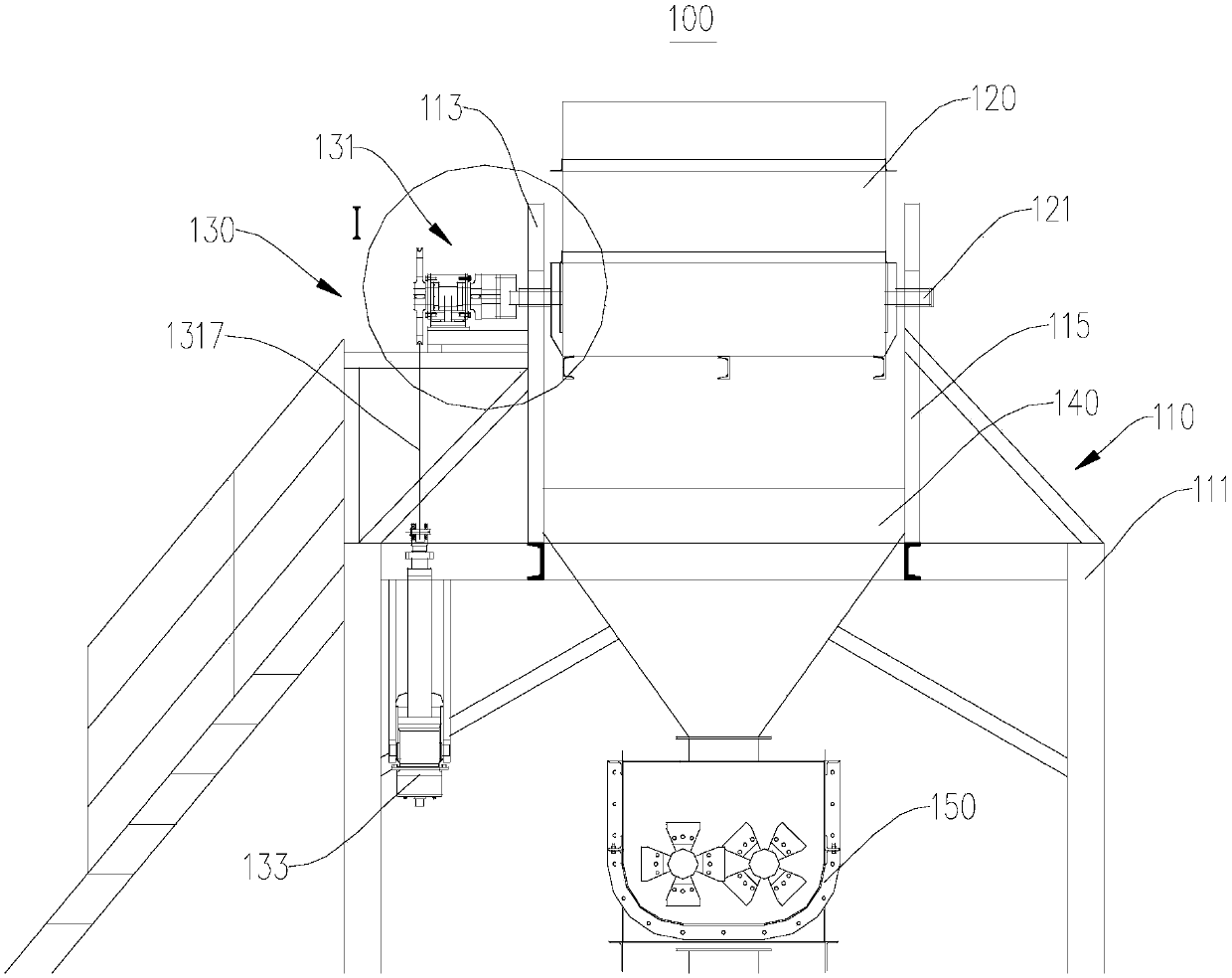

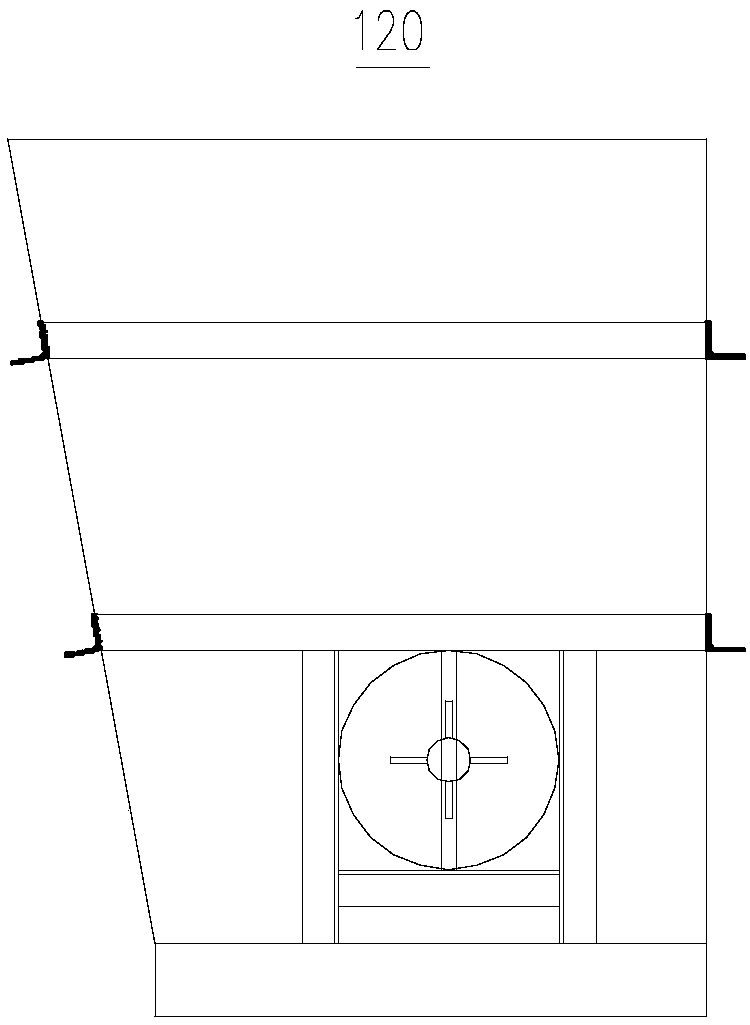

[0036] Please refer to figure 1 , the present embodiment provides a tar residue turning and dumping device 100 , including a support 110 , a transfer tank 120 , a rotating assembly 130 , a chute 140 and a mixing conveyor 150 . The transfer tank 120, the rotating assembly 130, and the chute 140 are arranged on the support 110. The rotating assembly 130 is connected with the transfer tank 120 to drive the transfer tank 120 to turn over. The chute 140 is arranged below the transfer tank 120. export connections.

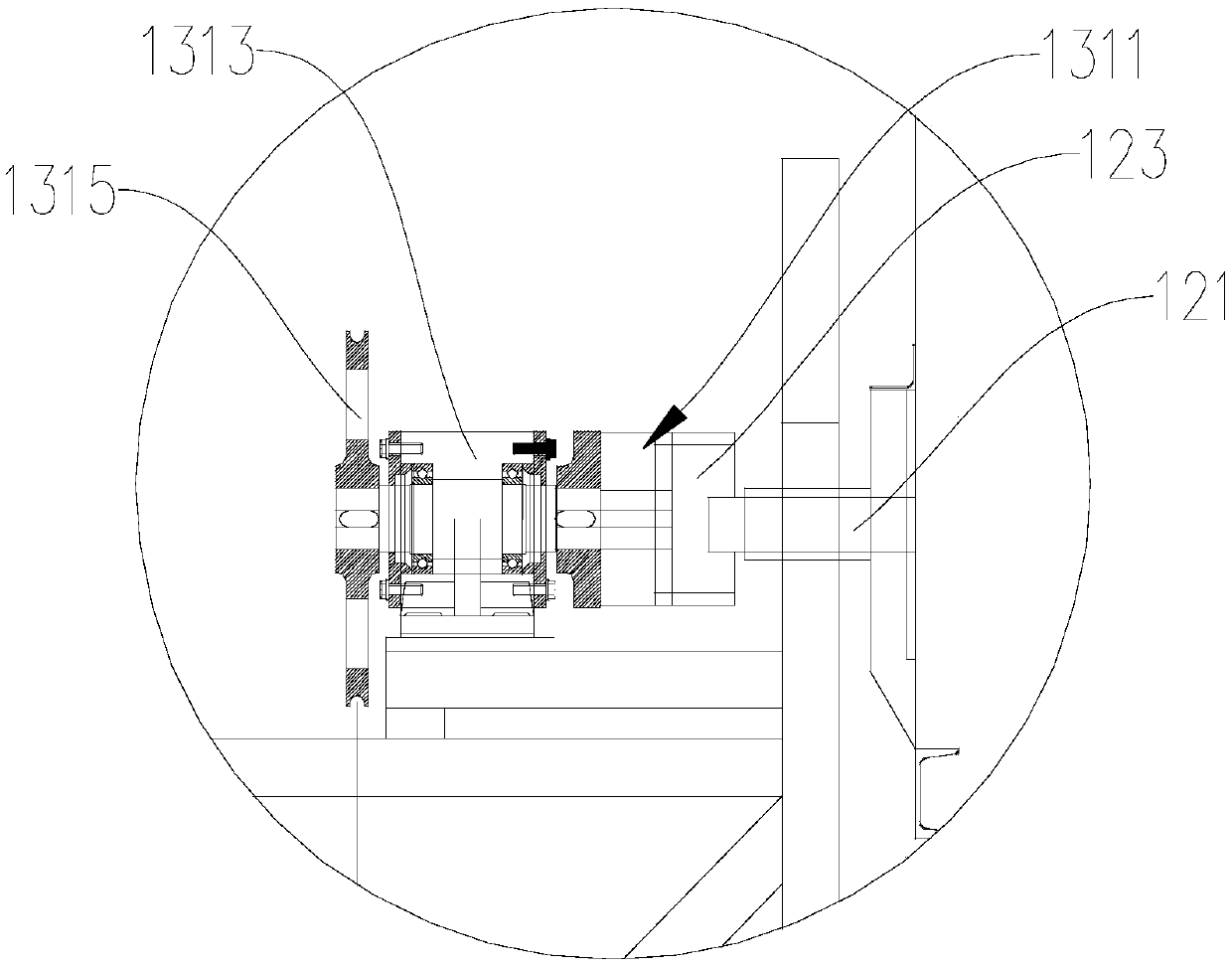

[0037] In this embodiment, the bracket 110 serves as a supporting structure, including a bracket body 111 , a first support rod 113 and a second support rod 115 , and the first support rod 113 and the second support rod 115 are fixedly connected to the bracket body 111 . In this embodiment, the first support rod 113 and the second support rod 115 have the same structure, and the first support rod 113 and the second support rod 115 are oppositely arranged, and both are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com