Process for grinding double bevel edges of glass

A double-bevel, glass technology, used in grinding machines, grinding heads, manufacturing tools, etc., can solve the problems of low production efficiency, small amount of chamfer grinding, glass deformation, etc., to save cost, improve work efficiency, reduce Effects of Correction Steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the examples.

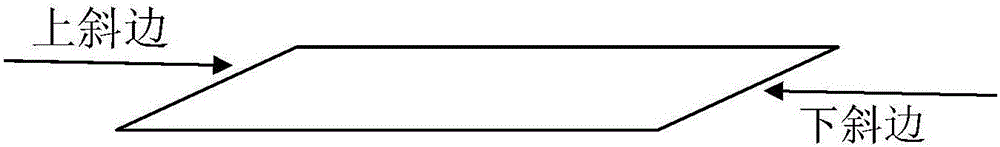

[0018] Glass double bevel edge grinding, the finished glass section see figure 1 .

[0019] Equipment and process transformation:

[0020] 1. Modification of edging grinding head

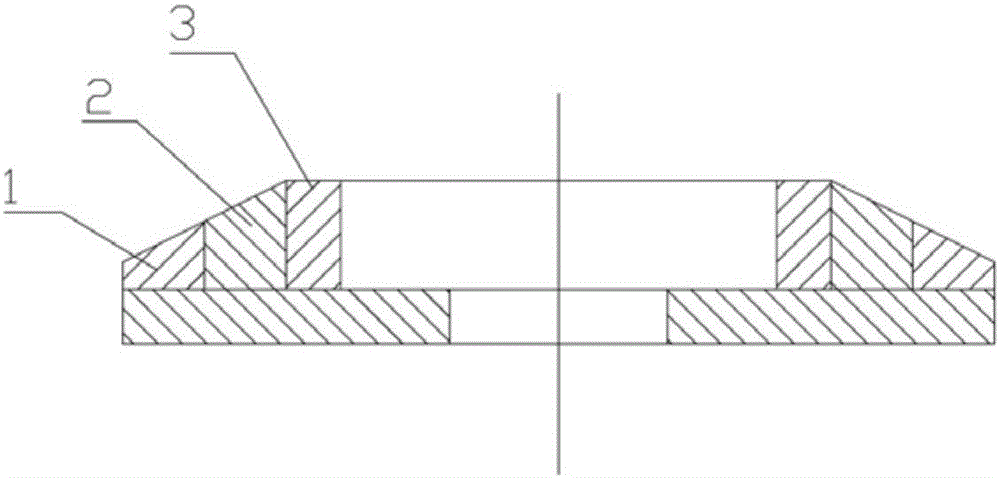

[0021] Install multiple beveled grinding wheels on the same motor, and the large circle of the outer ring is a small mesh grinding wheel, and then increase the mesh number successively, which can be three or four, figure 2 In the middle, three grinding wheels with different mesh numbers are installed on the same motor, the outer ring 1 is 100 mesh, the middle 2 is 140 mesh, and the inner ring 3 is 240 mesh.

[0022] 2. Change the chamfering grinding head to edging grinding head

[0023] If there is a chamfering grinding head under the glass on one side of the original double-sided edging machine, replace one side with an edging grinding head, if not, install it under the glass. After modi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com