An abrasive belt grinding device suitable for the grinding and polishing of the overall blisk blade surface and the intake and exhaust edges

A technology of intake and exhaust edges and integral blisks, which is applied to abrasive belt grinders, grinding/polishing equipment, grinding machines, etc., can solve the problems of over-grinding and under-grinding of blades, poor consistency of blades, and high labor intensity, etc., and achieve reduction The effect of reducing errors, ensuring consistency, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] specific implementation plan

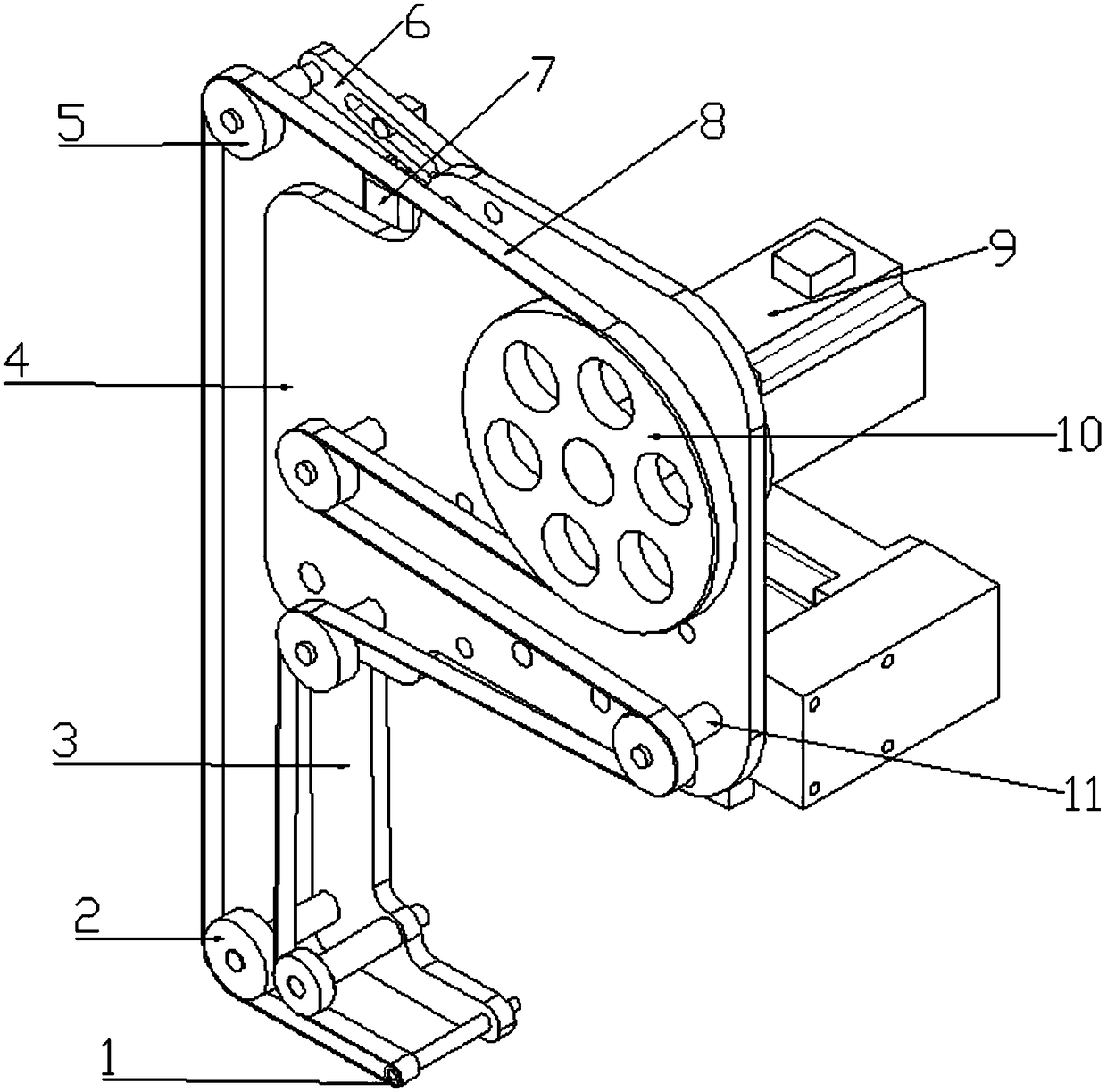

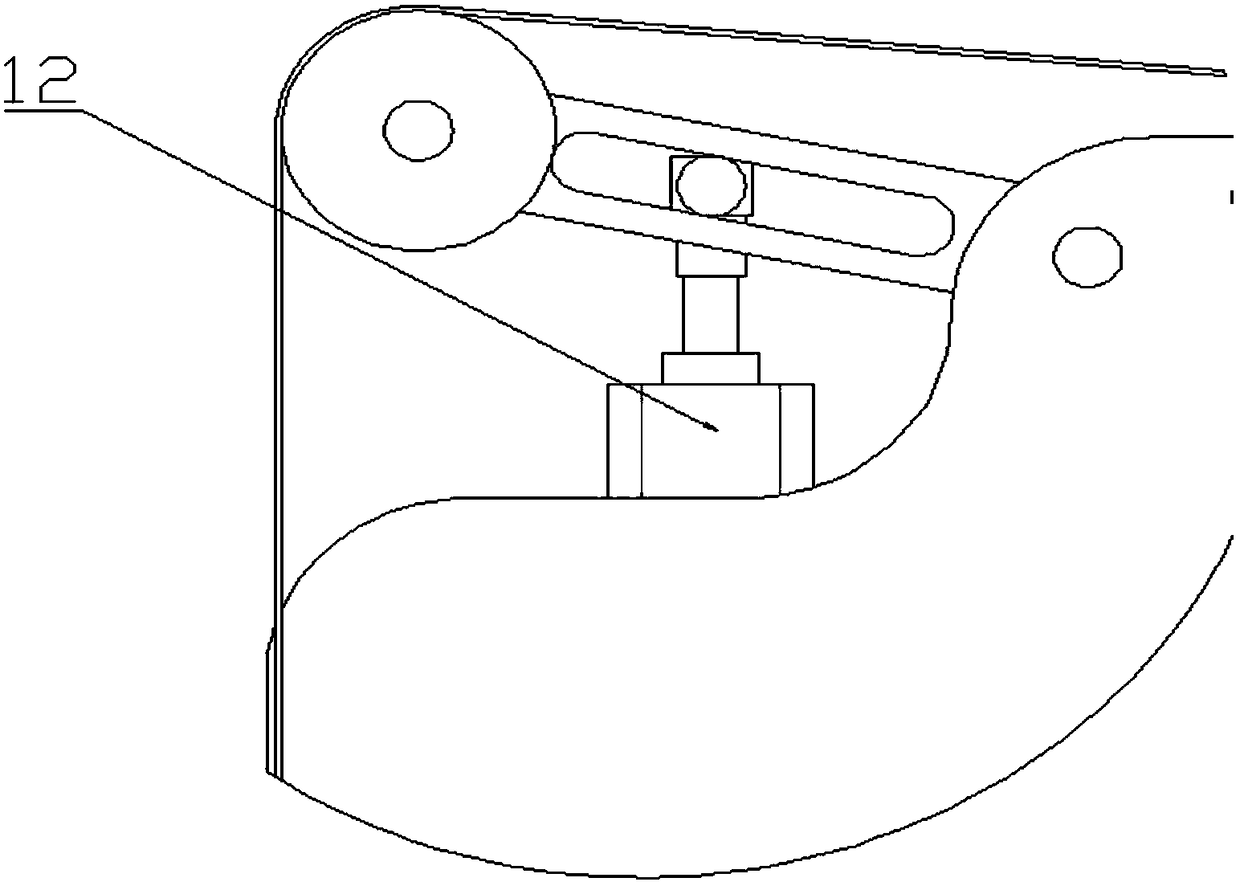

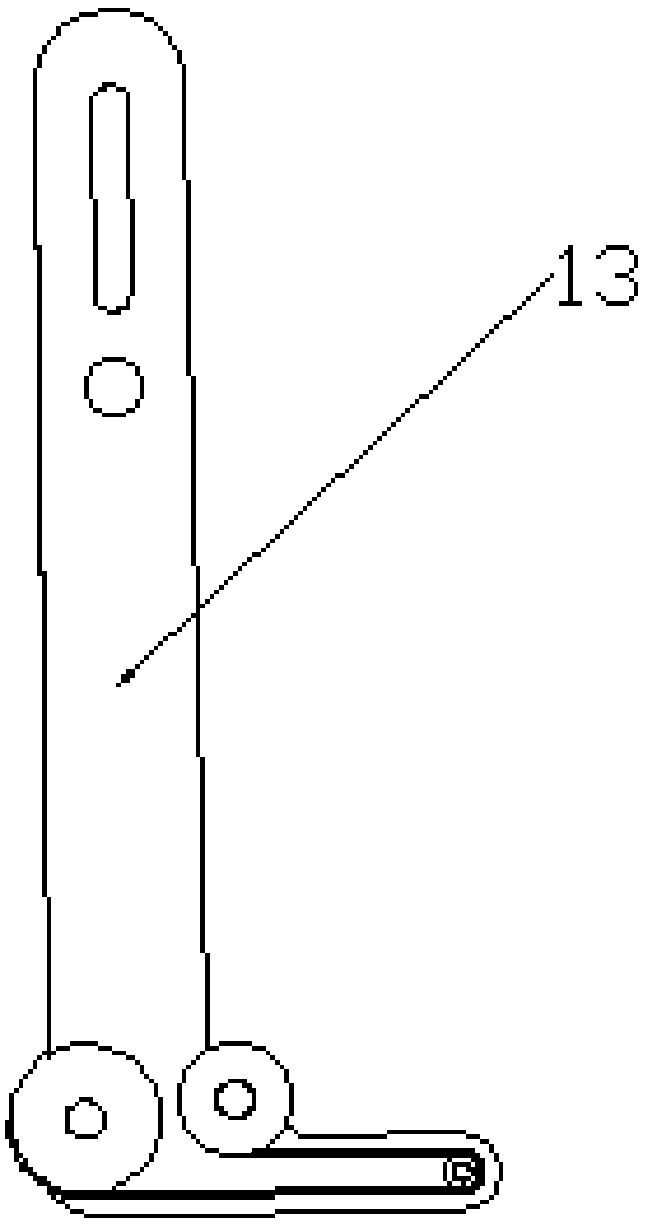

[0034] This grinding head device comprises driving wheel 10, some idler wheels, contact wheel mechanism 13, grinding force control mechanism 16, grinding head support plate 4, main shaft motor 9, some rigid shafts 11 are formed. The grinding head structure is installed on the machine tool with the numerical control turntable through the installation hole on the grinding head support plate, so as to realize the grinding and polishing of the inlet and outlet edges of the whole blisk.

[0035] Such as figure 1 Shown is an axonometric view of the device of the present invention, in which it can be clearly seen that each mechanism is fixed on the support plate of the grinding head, and the wheel trains are connected together through abrasive belts. The main shaft motor is installed on the grinding head support plate, and one end of the main shaft motor is equipped with a drive wheel, and the idler wheel is fixed on the grinding head support pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com