Automatic shearing and arranging frame mounting machine of lens injection molding semi-finished product

A technology of semi-finished products and cutting mechanisms, which is applied to other household appliances, optical components, household appliances, etc., can solve the problems of high labor intensity and late start of workers, and achieve the effect of promoting automation process, good management, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings.

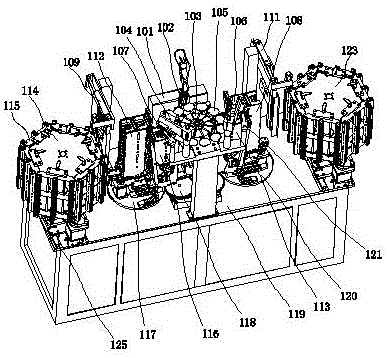

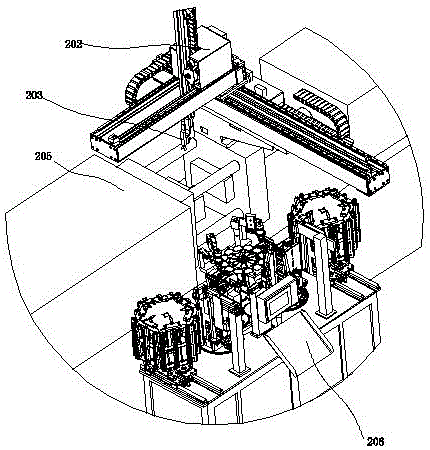

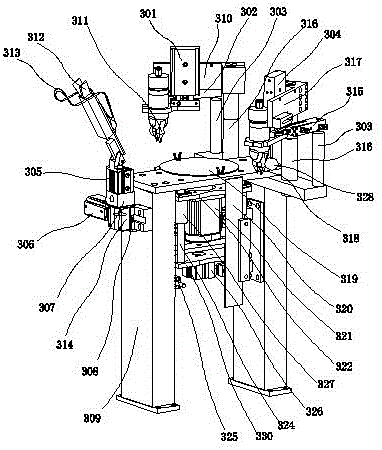

[0032] like figure 1 As shown, a lens injection molded semi-finished product automatic cutting, sorting and racking machine of the present invention includes a man-machine interface 101, a nozzle removal mechanism 102, a lens semi-finished lifting and rotating mechanism 103, a lens cutting mechanism 104, 106, and a lens stacking mechanism 113, 116 , 112,108, lens finishing mechanism 109,111, rack warehouse 114,123, hanger 115, alternate advance and retreat mechanism 117,120, alternate power mechanism 118; The advancing and retreating mechanisms 117, 120 are arranged in pairs, and are respectively arranged on the left and right sides of the automatic cutting, sorting and racking machine for semi-finished lens injection molding. The structural design and operation mode of the lens cutting mechanisms 104,106, lens stacking mechanisms 113,116,112,108, lens finishing mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com