Anti-slip netted line forming roller for footboard of sea farming net cage

A forming roller and anilox technology, which is applied in the field of non-slip anilox forming rollers on the pedals of marine aquaculture cages, to achieve the effects of convenient daily maintenance, guaranteed pressing effect, and convenient cleaning of dirt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

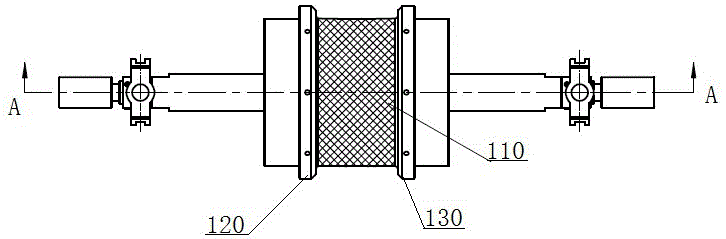

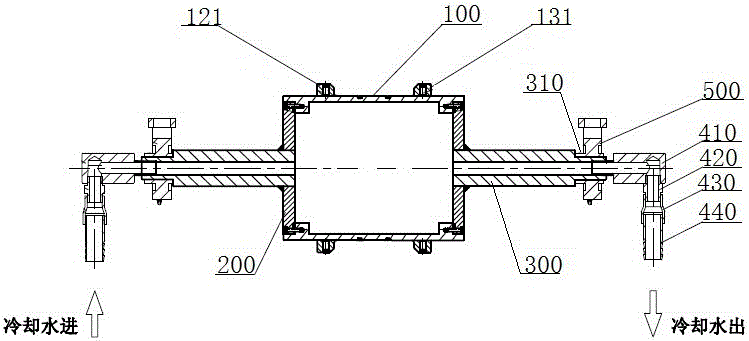

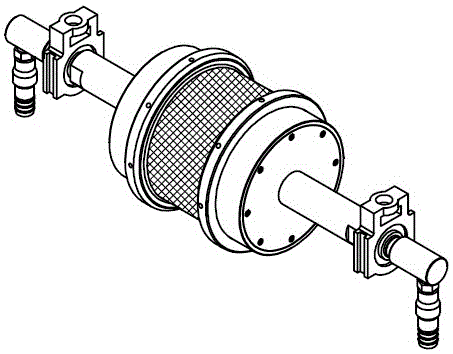

[0029] Such as Figures 1 to 3 As shown, a marine aquaculture net cage pedal anti-slip anilox forming roll is used to press out a non-slip structure on the surface of the profile 700. The forming roll includes a cylindrical hollow roll body 100, and the circumferential surface of the hollow roll body 100 There is an anilox 110, the two ends of which are respectively connected to flanges 200, the flange 200 is provided with a support shaft 300, and a passage is opened in the support shaft 300 to communicate with the inner cavity of the hollow roller main body 100, and the ends of the support shaft 300 Connected with water supply connector.

[0030] The circumferential surface of the hollow roller main body 100 is provided with a pair of side pressure clamps that can clamp profiles, and the side pressure clamps include a left pressure clamp 120 and a right pressure clamp 130, both of which are fixed by screws 121 and 131 respectively. On the circumferential surface of the hollo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com