3D printing device and printing method thereof

A 3D printing and printing platform technology, applied in the direction of additive processing, etc., can solve the problems affecting the printing quality of 3D objects, the middle bulge, etc., and achieve the effects of rapid exposure, improved accuracy, and improved printing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

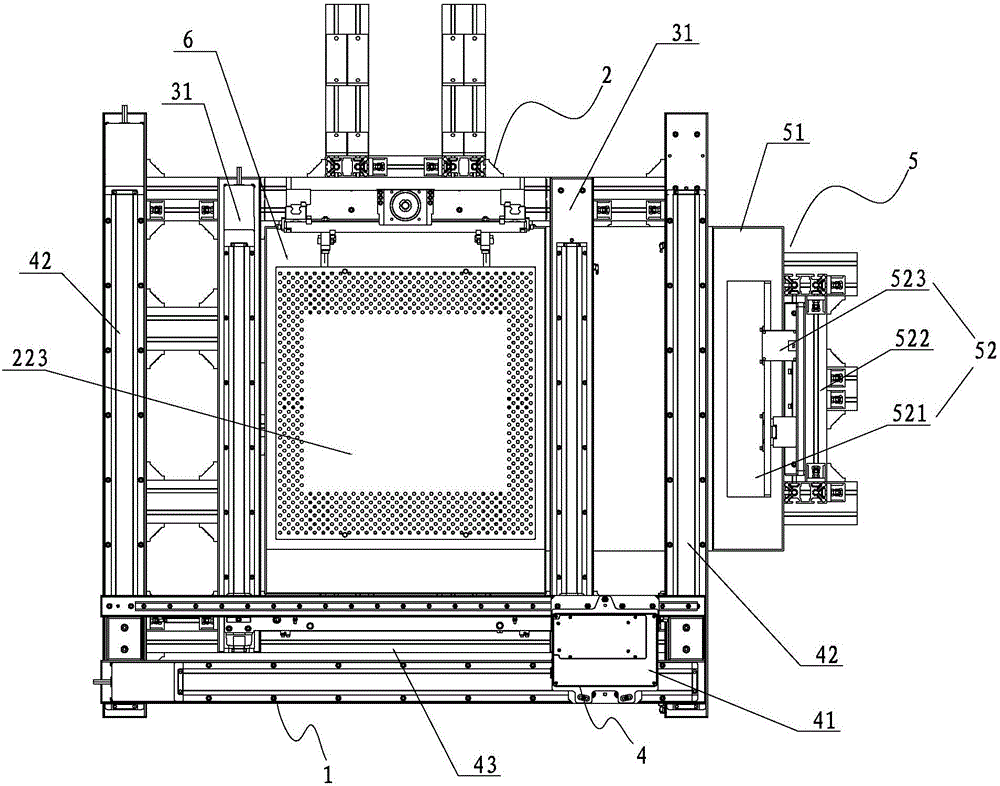

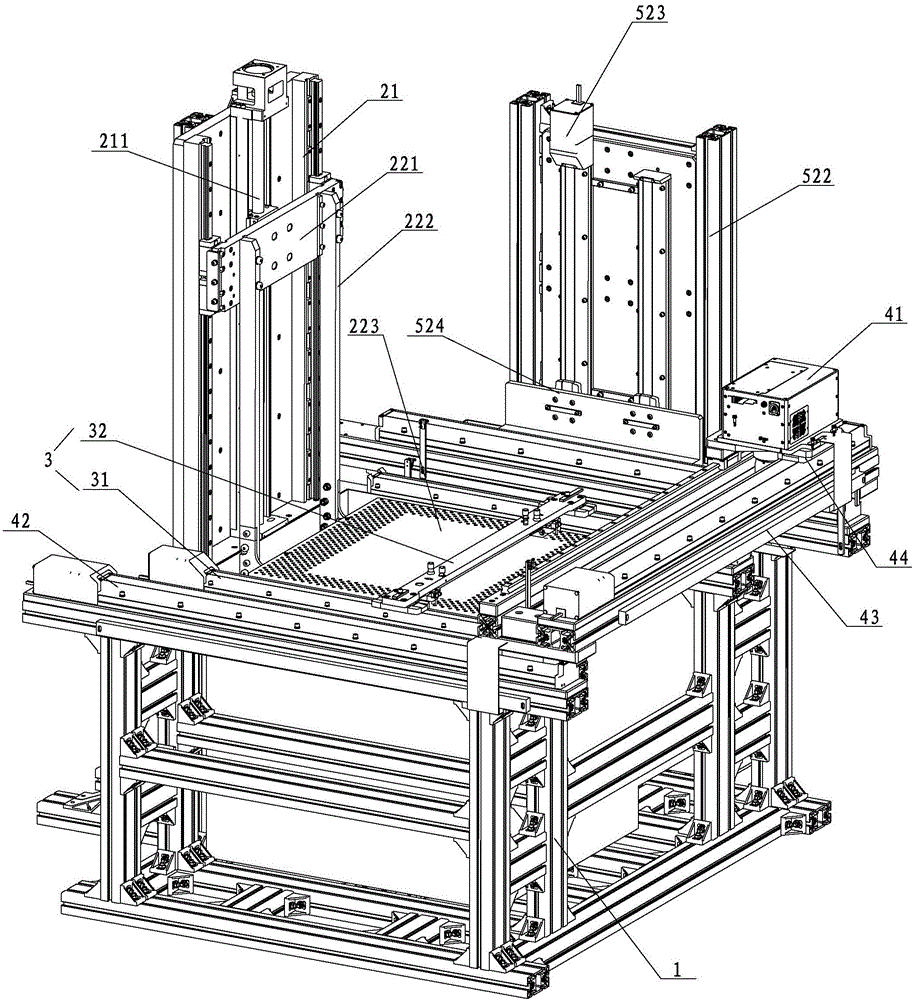

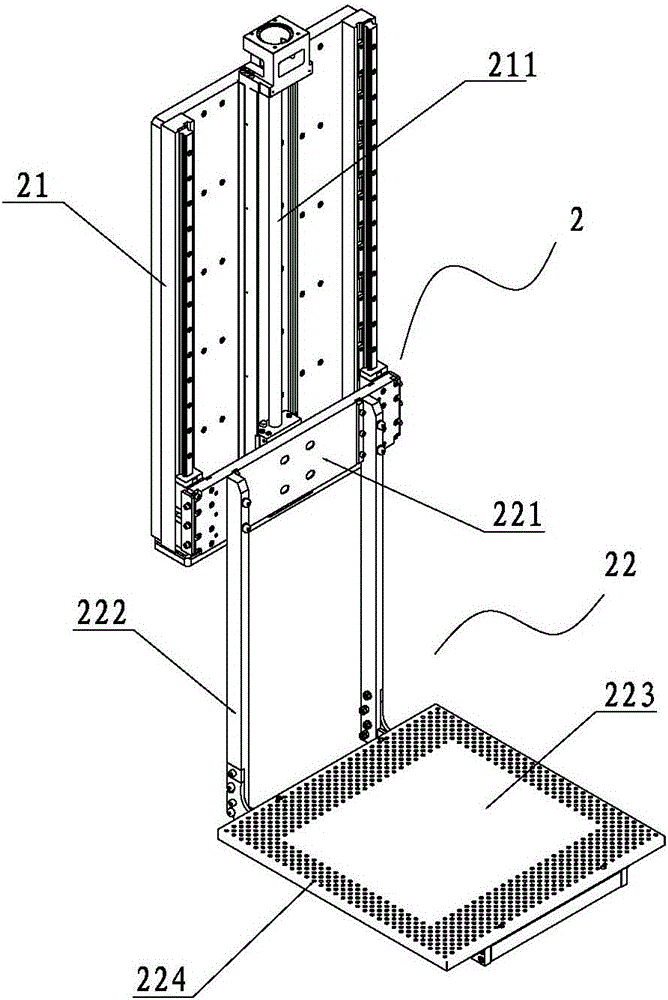

[0037] Such as Figure 1-3 As shown, a 3D printing device includes a base 1, a printing mechanism 2, a scraper mechanism 3, an exposure mechanism 4, a liquid replenishment mechanism 5 and a control mechanism, wherein a liquid tank 6 for holding a printing solution is installed in the base 1 , the printing mechanism 2 includes a module 21 and a printing platform 22 slidably mounted on the module 21. In this embodiment, the module 21 is provided with a longitudinal lead screw 211, and the printing platform includes a 211 connected to the slider 221, and the printing platform body 223 connected to the slider 221 through the connecting rod 222, the bottom of the lead screw 211 is connected to the lead screw motor, and the lead screw 211 is driven by the lead screw motor to rotate, so that the printing platform 22 moves along the module. 21 slides up and down, so that the printing platform body 223 can move up and down in the liquid tank 6. There are several through holes 224 arou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com