Public clamping device for printing work

A printing operation, clamping and positioning technology, applied in printing, printing presses, rotary printing presses, etc., can solve problems such as waste of resources, and achieve the effect of improving service life, saving manpower and material resources, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

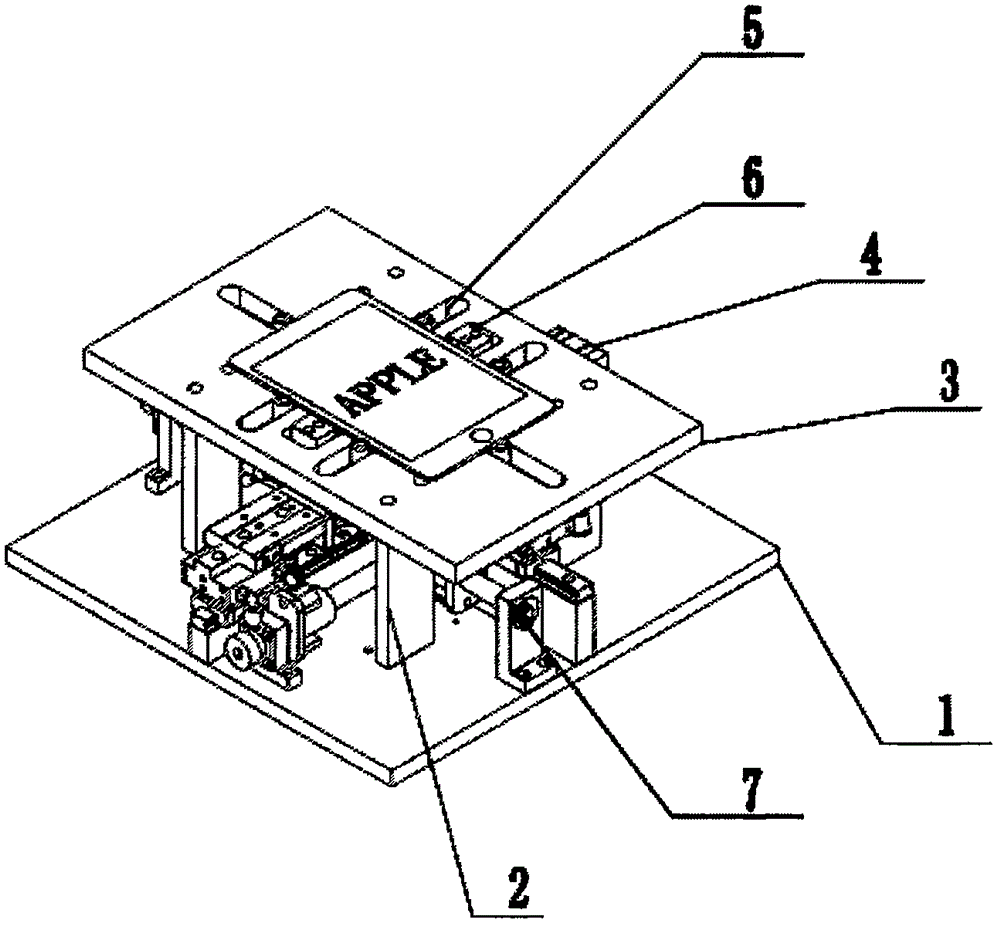

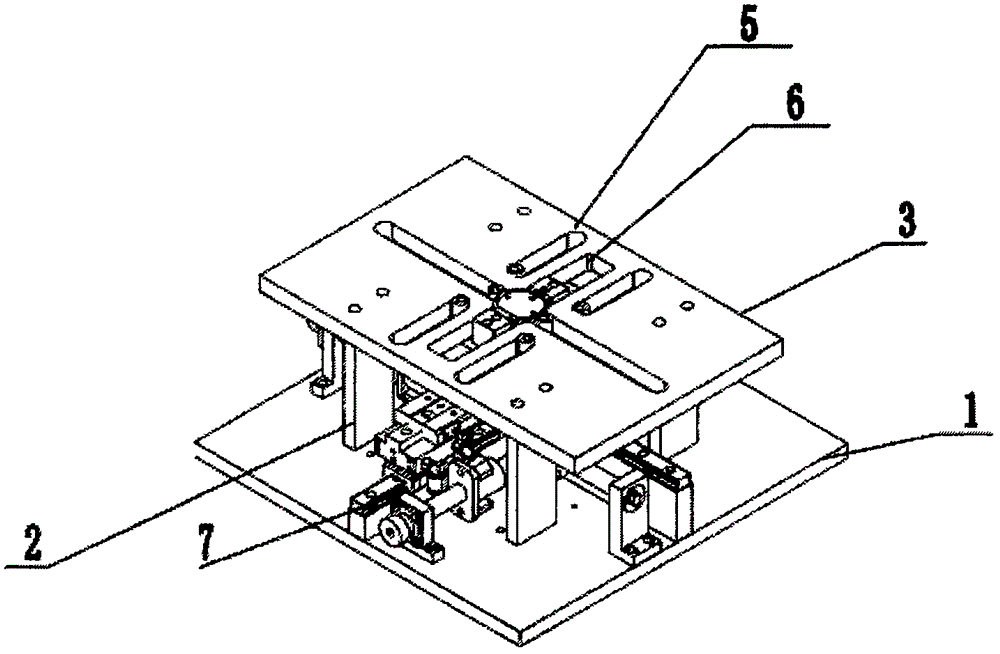

[0012] see Figure 1-Figure 2 As shown, the technical solution adopted in this embodiment is: a common clamping device for printing operations, which includes a base 1, a support column 2, a workbench 3, a cylinder slide 4, a clamping top block-5, a clamping Side top block two 6, left and right rotation T-type screw rod 7; Support column 2 is arranged on the base 1, and workbench 3 is arranged on the upper end of support column 2, and cylinder slide table 4 is located at workbench 3 lower ends, and workbench 3 is provided with There are 6 slots 1 and 2 slots 2 connected to the bottom, and the 6 slots 1 are respectively provided with 6 clamping top blocks 1 5, through 6 clamping top blocks 1 5 and 4 cylinders at the bottom With the cooperation of slide table 4, preliminary clamping and correction can be performed on the cover plate of the mobile phone. Through the two clamping top blocks 15 and 2 clamping top blocks 26 arranged in slot 1 and slot 2, smart wearable products can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com