Two-color gradually-varied-mesh gas-guiding three-layer mesh fabric production method and mesh fabric

A technology of three-layer mesh and production method, which is applied in the direction of heating/cooling fabrics, textiles and papermaking, fabric surface trimming, etc., can solve the problem of improper matching of yarn materials in pattern design, low precision of mesh fabrics, and reduced strength of fabrics, etc. problems, to solve the problem of hot gas backflow and ventilation problems, reduce hot air backflow, and achieve the effect of good fabric strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the examples, but the present invention is not limited to the following examples.

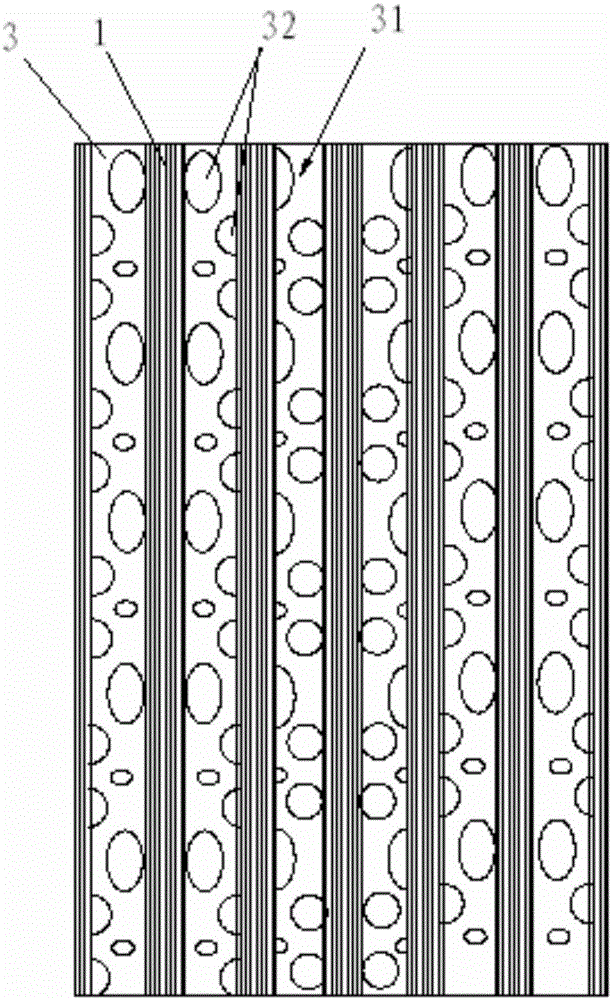

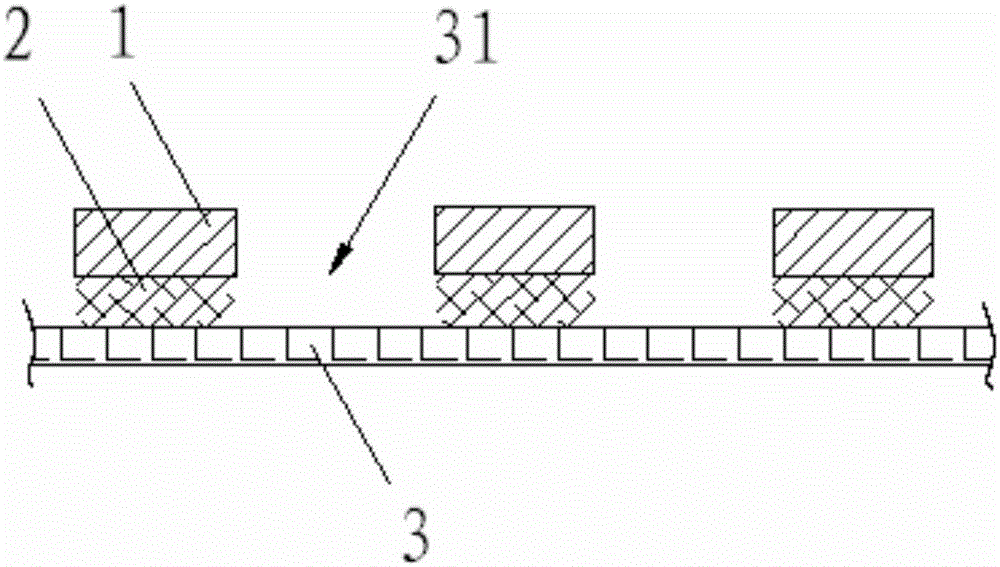

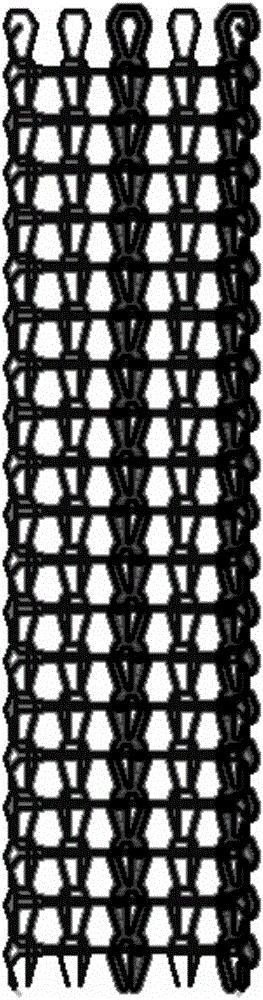

[0027] A method for producing a two-color gradient mesh air-conducting three-layer mesh fabric, using a double-needle bed knitting machine, and weaving six comb bars arranged in sequence from the front needle bed to the rear needle bed, including the following steps:

[0028] (1) Warping: bar GB1 warping 150D polyester semi-gloss yarn, polyester content accounts for about 4%-6%, 6 pan heads each with 190 yarns (double-layer and bar GB2 common to reduce warping The waste of warping); the warping bar GB2 is 150D polyester semi-gloss yarn, and each of the 6 pan heads has 190 yarns (the double-layer and GB1 are common to reduce the waste of warping), and the polyester content accounts for 4%-6%; Comb GB3 warping 200D polyester glossy filament yarn and 210D nylon semi-gloss yarn, nylon content accounts for 15%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com