Construction Method for Installing Steel Bars of Elevator Shaft Side Wall in Raft Foundation

A technology of raft foundation and construction method, which is applied in basic structure engineering, construction material processing, construction, etc. It can solve the problems of large amount of steel reinforcement on the side wall of the elevator shaft, 2# tower crane cannot cover, and tower crane utilization rate is low. , to achieve the effect of shortening the binding period, avoiding accidents caused by steel bars, and convenient and quick construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

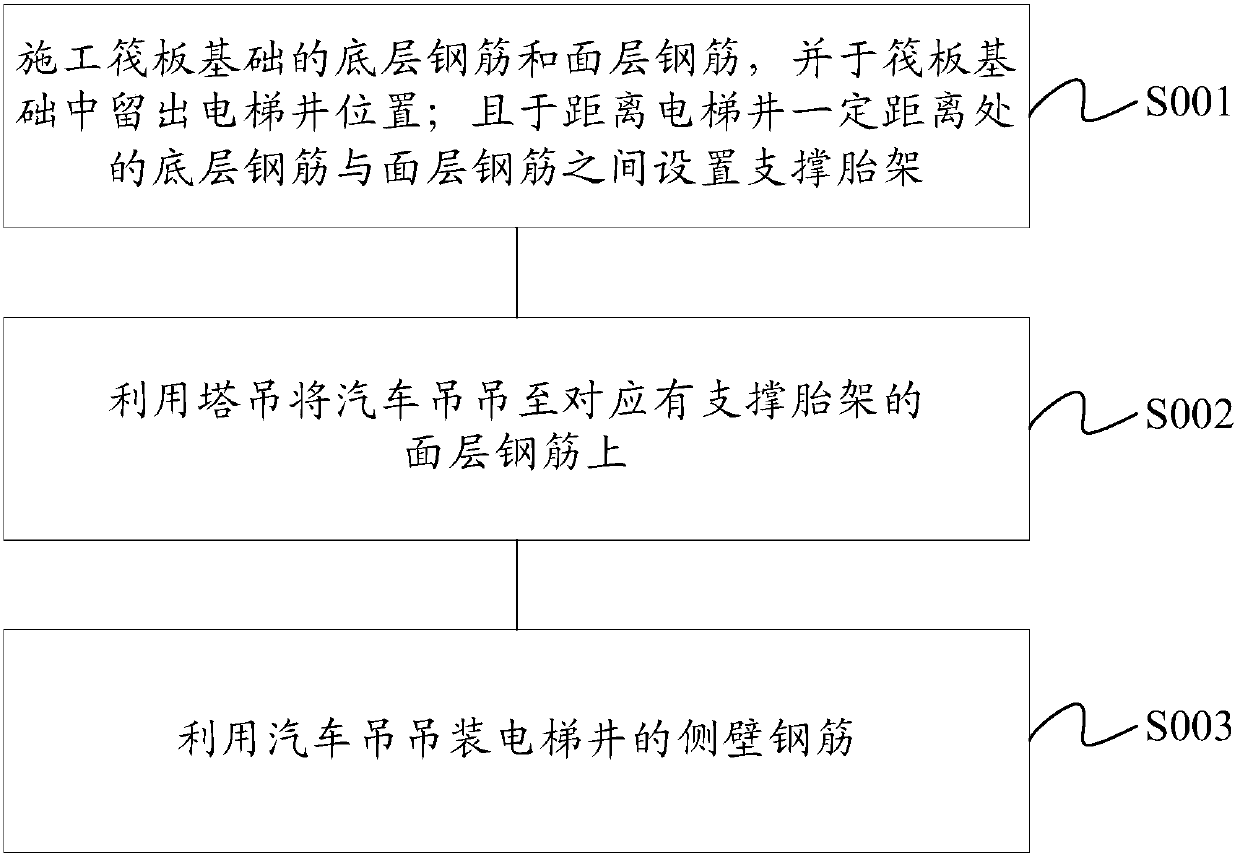

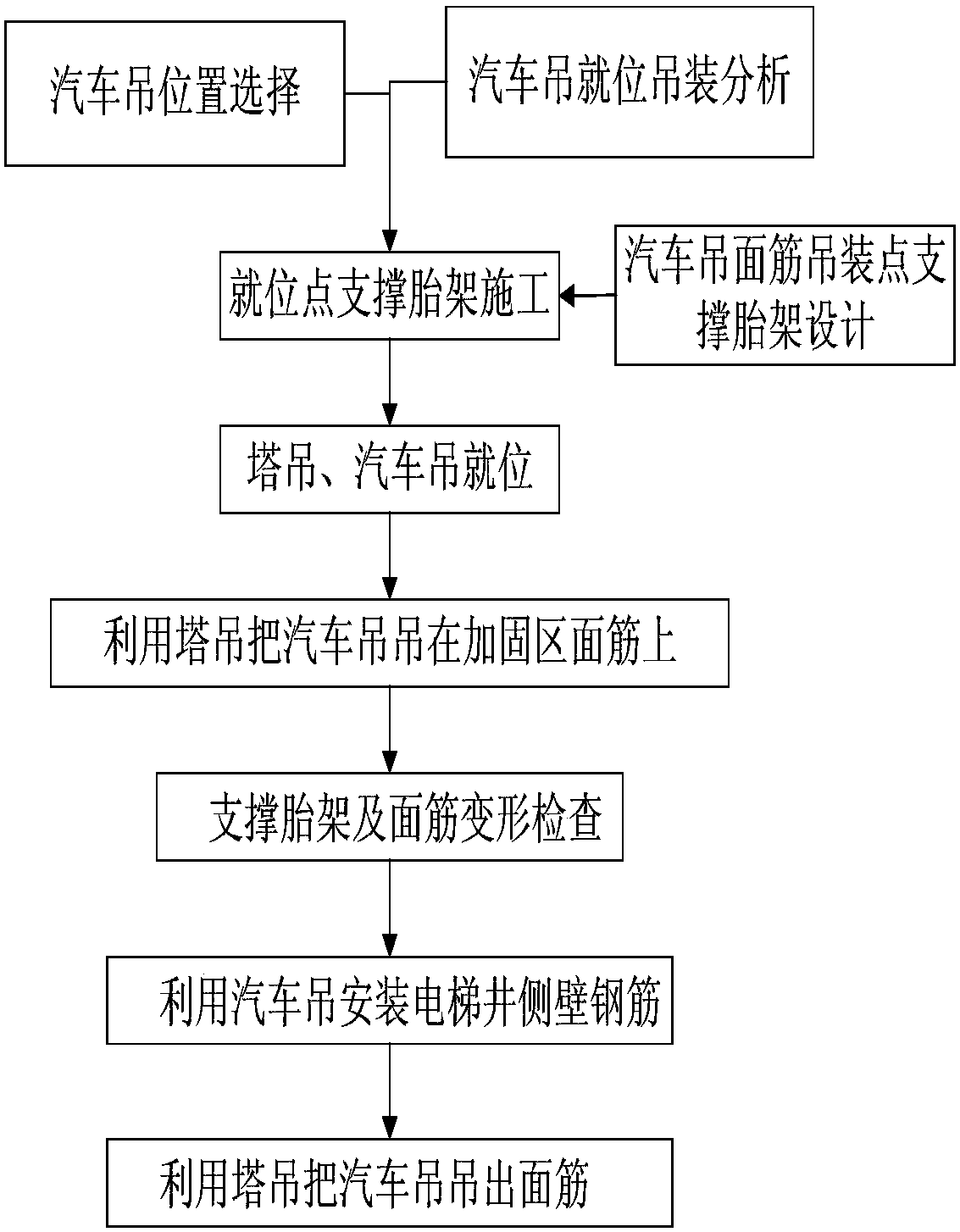

[0046] see first figure 1 As shown, the construction method of the present invention to install elevator shaft side wall steel bars in the raft foundation mainly includes the following construction techniques:

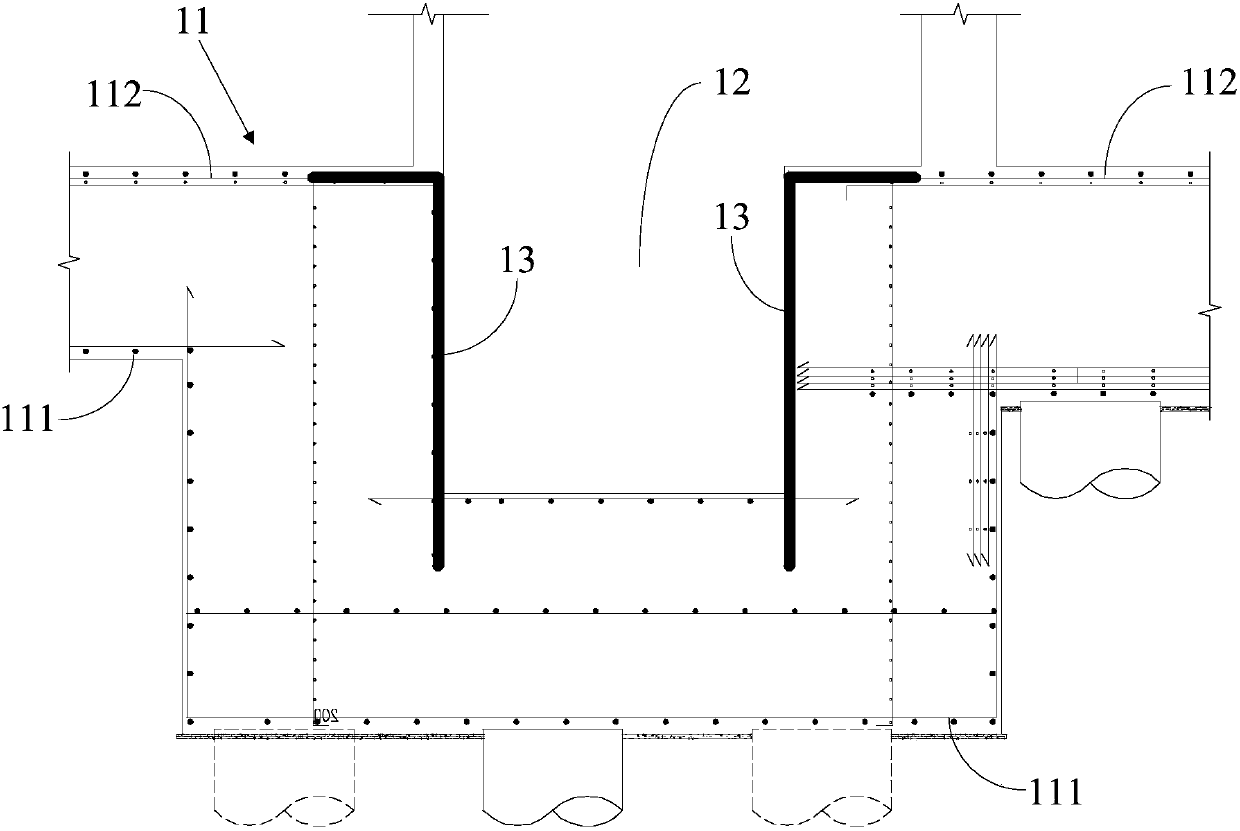

[0047] S001: Construct the bottom reinforcement and surface reinforcement of the raft foundation, and reserve the location of the elevator shaft in the raft foundation; and set up a supporting frame between the bottom reinforcement and the surface reinforcement at a certain distance from the elevator shaft;

[0048] S002: Use the tower crane to hoist the car to the surface steel bar corresponding to the supporting tire frame;

[0049] S003: Use the truck crane to hoist the side wall reinforcement of the elevator shaft.

[0050] The main idea is: prevent the truck crane on the raft foundation, and use the truck crane instead ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com