Drill hole arrangement structure and permeability-increasing method for coal seam high-pressure waterpower slotted fracturing

A technology for hydraulic slitting and drilling arrangement, which is used in safety devices, earth-moving drilling, drilling with liquid/gas jets, etc., can solve the problems such as the difficulty in controlling the expansion direction of fracturing cracks and the small influence range of slitting and drilling, etc. Achieve the effect of reducing outburst risk, shortening the time to reach the standard of extraction, and improving the efficiency of extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

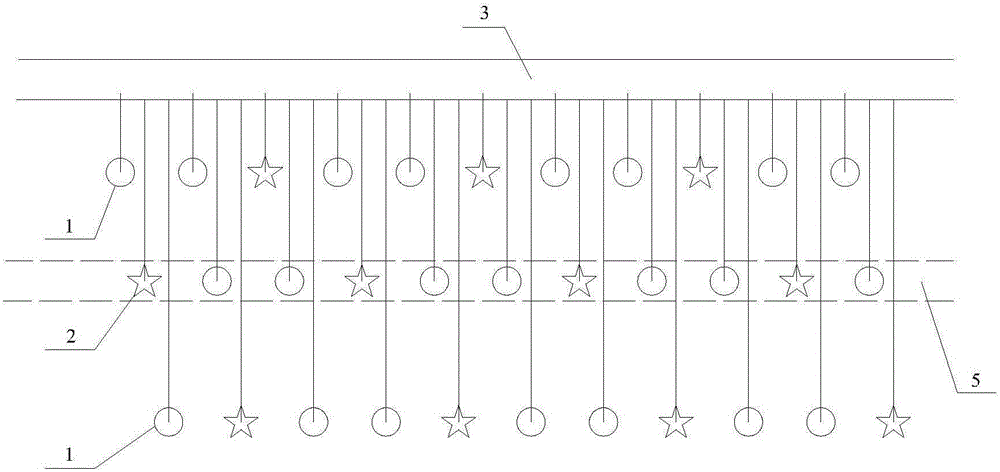

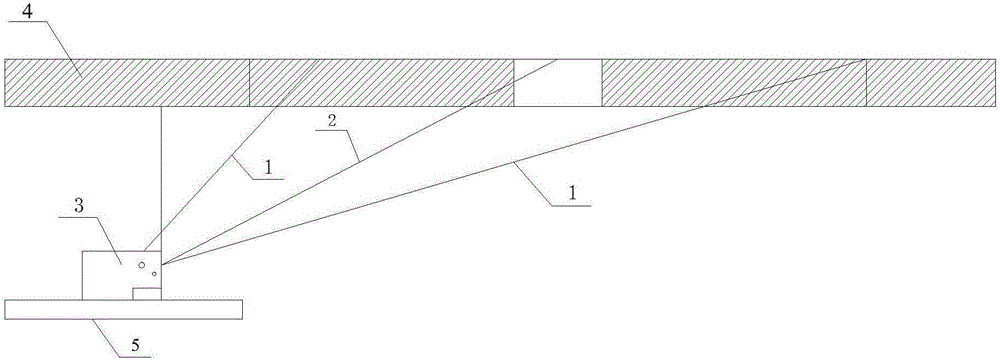

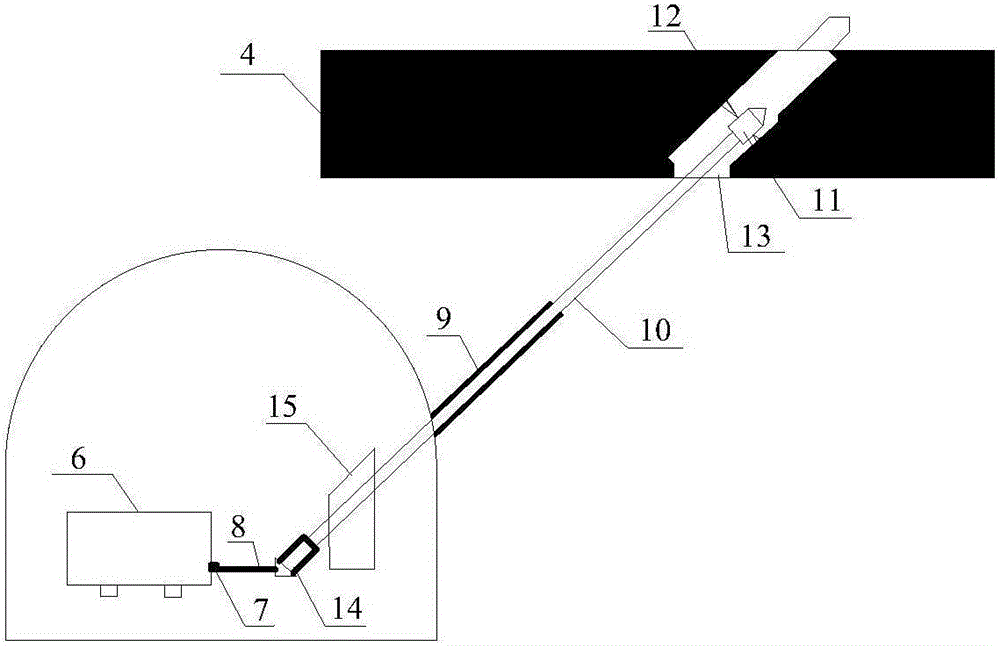

[0025] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, this embodiment is a drilling layout structure for high-pressure hydraulic slotted fracturing of coal seams. The construction site is selected from the low-level gas drainage roadway of the 12408 working face of a coal mine, and the bottom drainage roadway 3 is directed to the coal seam 4 along its length direction. There are three rows of drill holes in the direction, each row of drill holes includes a plurality of slotted drill holes 1 and a plurality of fracturing drill holes 2, the opening point of one row of drill holes is located on the roof of the roadway, 1m away from the side of the roadway; the other two rows The opening points of the drilled holes are all located on the side of the roadway, and the distance from the roadway floor 5 is 2m; two slotted drilled holes 1 are arranged at equal intervals between the adjacent two fracturing drilled holes 2 of each row of drilled holes, and the adjacent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com