Oil leakage preventing device used for turbosupercharger

A turbocharger, oil leakage prevention technology, applied in the direction of machines/engines, engine components, mechanical equipment, etc., can solve problems such as prone to oil leakage, affect the normal operation of the turbocharger and the performance of the whole machine, and achieve high performance The effect of small influence and simple assembly relationship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

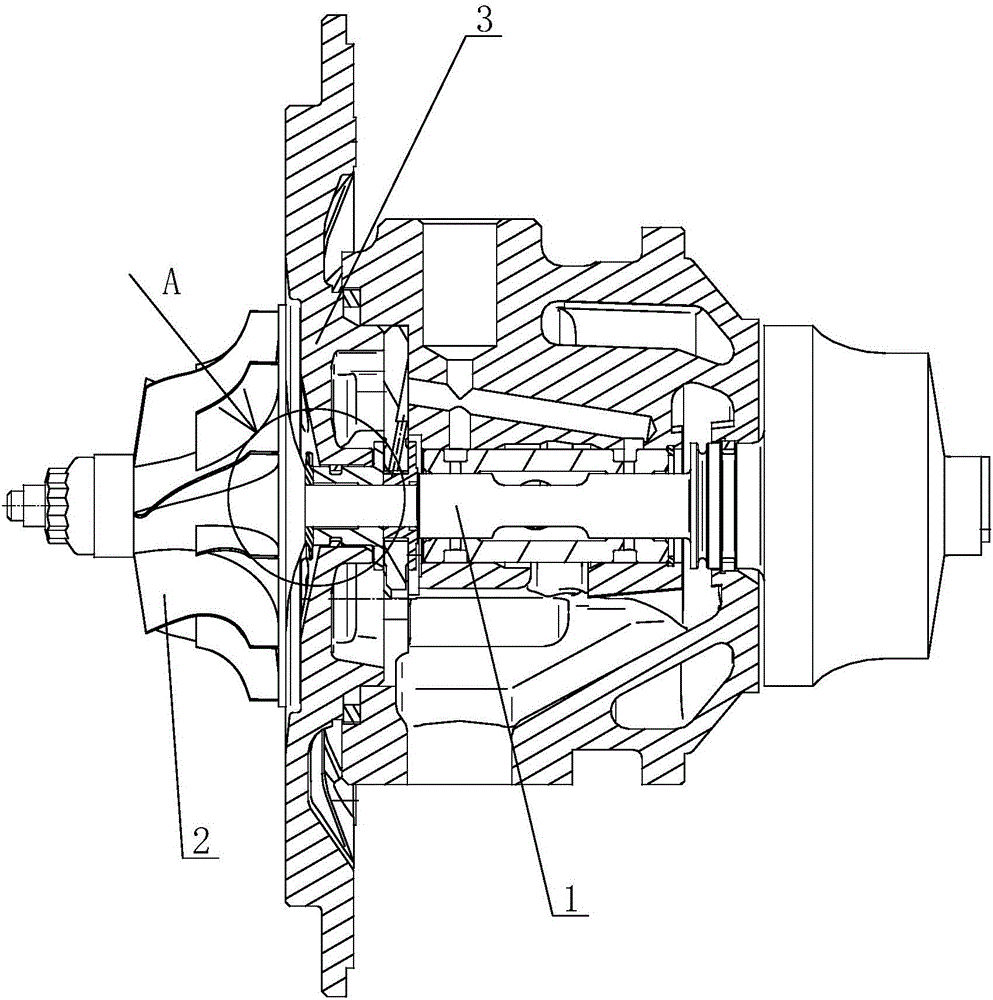

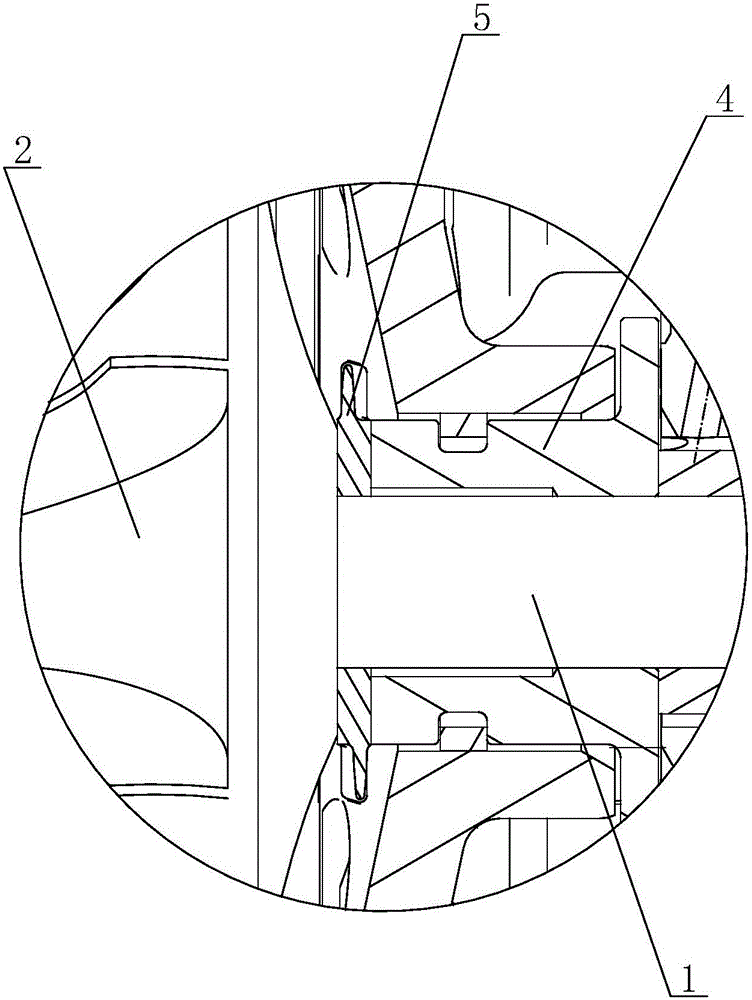

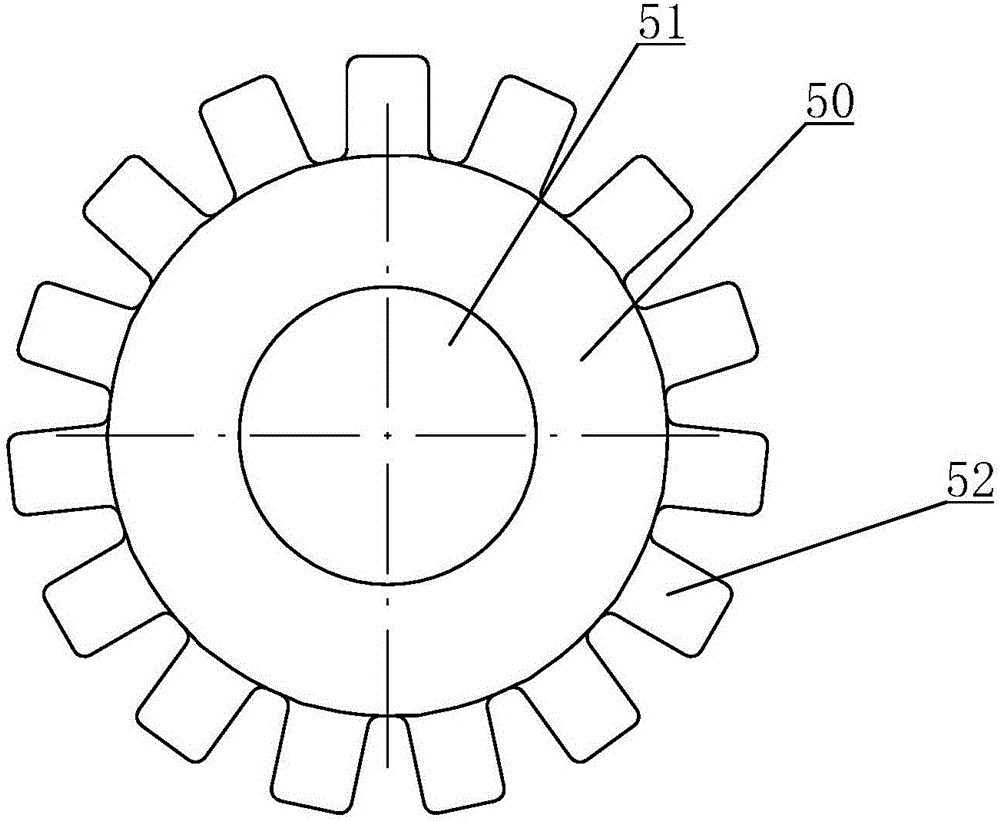

[0018] see Figure 1 to Figure 4 As shown, in this embodiment, an anti-oil leakage device for a turbocharger includes a core rotor 1, an impeller 2 and an intermediate housing 3, and a gap between the core rotor 1 and the intermediate housing 3 Set the shaft seal fixed sleeve 4, the impeller 2 is installed on the core rotor 1 outside the shaft seal fixed sleeve 4, and the core rotor 1 is installed between the shaft seal fixed sleeve 4 and the impeller 2 The anti-oil leakage fan 5, the anti-oil leakage fan 5 is processed by casting, the overall diameter is 20mm, and the anti-oil leakage fan 5 includes a body 50, and the center of the body 50 is provided with a matching core rotor 1 There are mounting holes 51 provided on the outer diameter, and 12 fan blades 52 are evenly distributed on the outer ed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com