Time sequence control method for increasing ignition success rate of ramjet

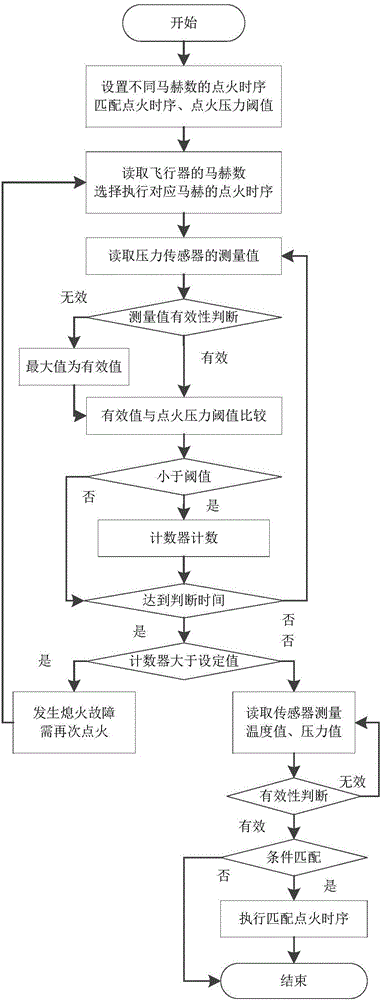

A ramjet and timing control technology, applied in the field of ramjet, can solve the problems of not being able to judge whether the ignition is successful, unable to realize the ignition, not having the combustion chamber monitoring function, etc., to improve the ignition success rate, reliable ignition, and prevent flameout failures. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0042] There are two pressure sensors P installed in the combustion chamber of the engine 1 , P 2 , two temperature sensors T 1 , T 2 , a speed sensor S is installed on the aircraft fuselage 1 . In the engine controller, for Mach numbers of 4.5M and above, 3 to 4.5M, 3M and below, respectively set ignition sequence 1 to match ignition sequence 1; ignition sequence 2 to match ignition sequence 2; ignition sequence 3 to match ignition sequence 3. The specific content of each time sequence is as follows:

[0043]Ignition sequence 1: Turn on fuel nozzle 1 and nozzle 2 in the 1s, start injecting fuel at a speed of 100g / s from nozzle 1 and turn on the igniter in the 1.5s, and inject fuel at a speed of 80g / s in nozzle 2 in the 3s;

[0044] Ignition sequence 2: Turn on fuel nozzle 2 and nozzle 3 at 0.5s, and start injecting fuel at nozzle 3 at a speed of 70g / s and turn on the igniter at 1.2s, and inject fuel at a speed of 50g / s at nozzle 2 at 2.7s;

[0045] Ignition sequence 3:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com