A pigging ball for pipeline plugging

A technology for pigging balls and pipelines, which is applied in the field of pigging balls, can solve the problems of resistance in the recovery process and the poor sealing of pipeline pluggers, and achieve the effects of reducing resistance, convenient operation and strong passability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

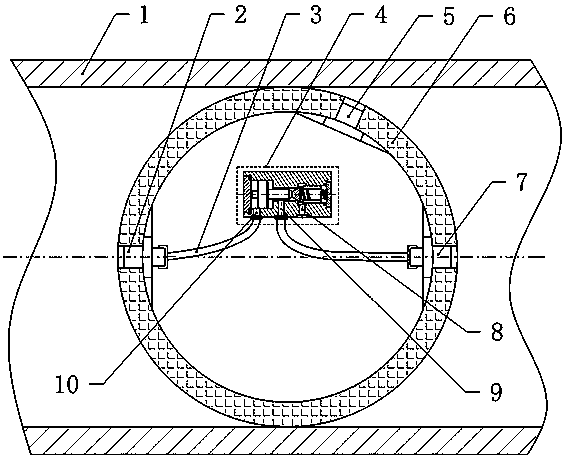

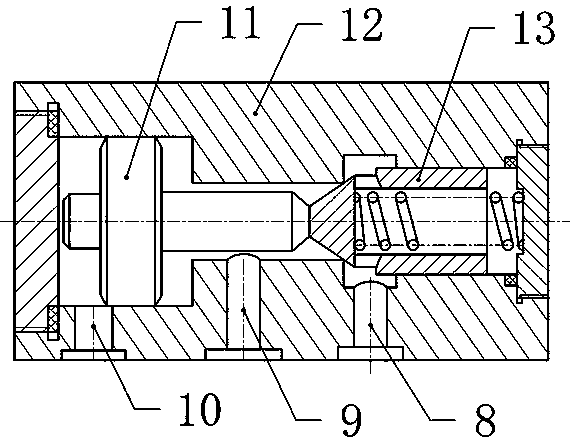

[0016] The present invention is not limited by the following implementation examples, and specific implementation manners can be determined according to the technical solutions of the present invention and actual conditions. Combine below figure 1 , figure 2 The present invention is described below. The positional relationship of up, down, left, right, etc. is based on the attached figure 1 determined by the layout direction.

[0017] The housing 6 is a rubber spherical shell, and the pressure introduction joint 2 is installed in the housing 6, and the pressure introduction joint 2 communicates with the outside of the housing 6; the injection joint 7 is installed in the housing 6, and the injection joint 7 communicates with the outside of the housing 6. The joint 7 injects liquid into the housing 6 . The pressure introduction joint 2 and the injection joint 7 are oppositely arranged on both sides of the casing 6 .

[0018] The controllable one-way valve 4 is arranged ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com