Basin-type insulator with embedded probe and manufacturing method thereof

A basin-type insulator and manufacturing method technology, applied in the direction of insulators, electrical components, circuits, etc., can solve the problems of poor probe installation position, poor probe sensitivity, etc., to improve the detection technology level, reduce maintenance time, and reduce external radiation noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

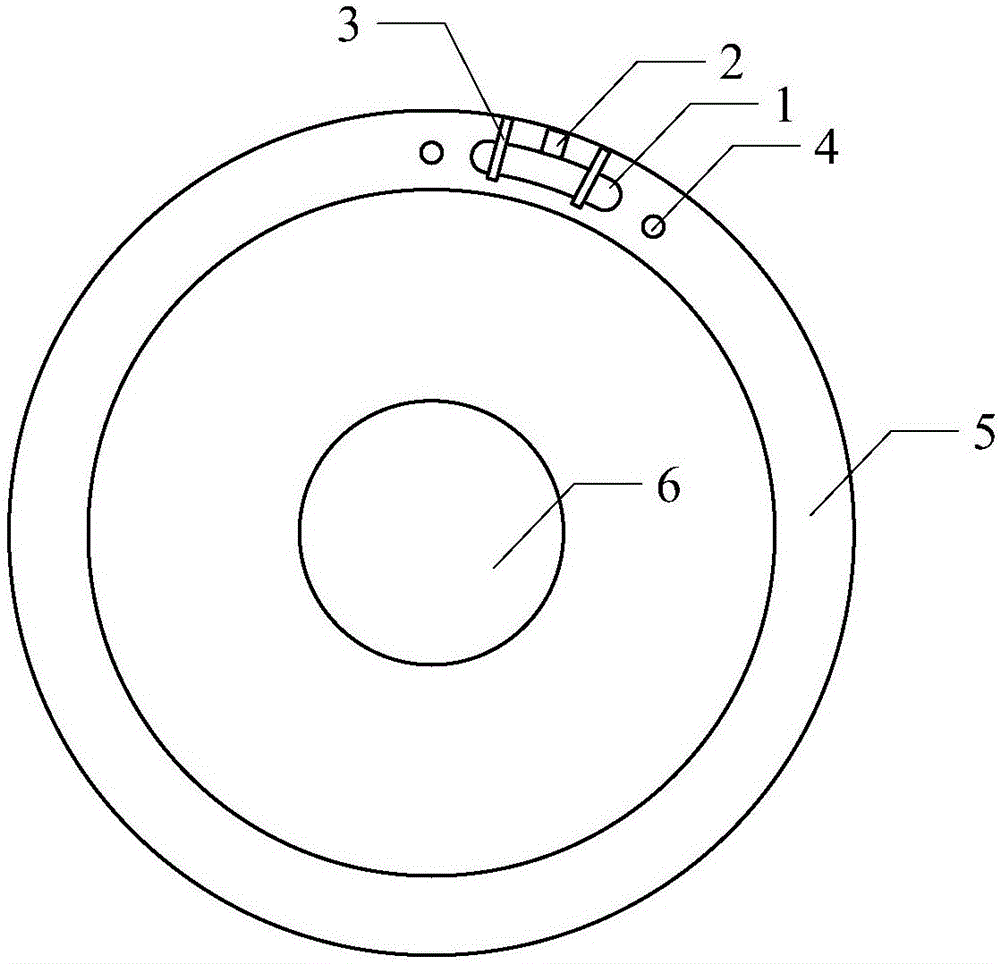

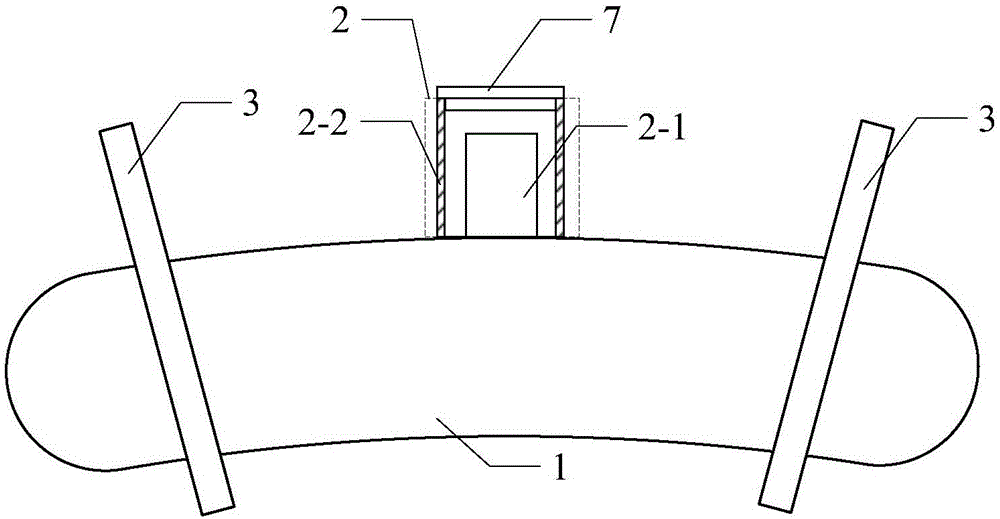

[0039] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, a pot insulator with embedded probes described in this embodiment, which includes a pot insulator body 5; two bolt holes 4 are provided at the edge of the pot insulator body 5; A central hole 6 is provided at the center of the type insulator body 5;

[0040] It also includes probe 1 and connector 2;

[0041] The probe 1 is arranged between the two bolt holes 4 of the pot insulator body 5;

[0042] One end of the connector 2 is connected to the probe 1, and the other end of the connector 2 is located outside the pot insulator body 5;

[0043] The connector 2 includes an inner connector 2-2 and a cable connector 2-1; the inner connector 2-2 is cylindrical, and one end of the inner connector 2-2 is connected to the probe 1, and the cable connector 2-1 is located at Inside the internal connector 2-2; and, one end of the cable connector 2-1 is also connected to the probe 1; the cab...

specific Embodiment approach 2

[0045] Embodiment 2: This embodiment is to further define the pot insulator with embedded probe described in Embodiment 1. In this embodiment, the internal connector 2-2 is an aviation socket; The socket is used to match the aviation plug of the external signal acquisition device.

specific Embodiment approach 3

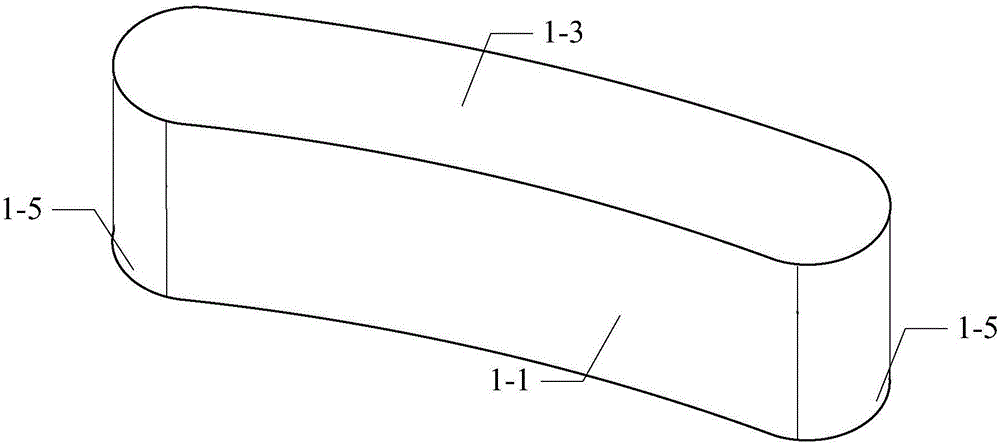

[0046] Specific implementation mode three: combination image 3 and Figure 4 Describe this embodiment. This embodiment is to further limit the pot insulator with embedded probes described in the first embodiment. In this embodiment, the probe 1 includes an inner arc surface 1-1, an outer arc surface 1-2, upper surface 1-3, lower surface 1-4 and two end surfaces 1-5;

[0047] The two end surfaces 1-5 of the probe 1 are arranged oppositely, the upper surface 1-3 and the lower surface 1-4 of the probe 1 are arranged oppositely, and the inner arc surface 1-1 and the outer arc surface 1-2 of the probe 1 are oppositely arranged;

[0048] The bending radians of the inner arc surface 1-1 and the outer arc surface 1-2 are the same as the edge bending arc radians of the pot insulator body 5, and the bending directions of the inner arc surface 1-1 and the outer arc surface 1-2 are the same as The bending direction of the edge of the basin type insulator body 5 is also the same;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com