Integrated sound production and transmission sensor

A technology for acoustic sensors and sound-emitting devices, which is applied to sensors, loudspeakers, electrical components, etc., can solve the problems of unstable product performance, increased installation errors, poor consistency, etc., and achieves the effect of easy installation and stable product performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

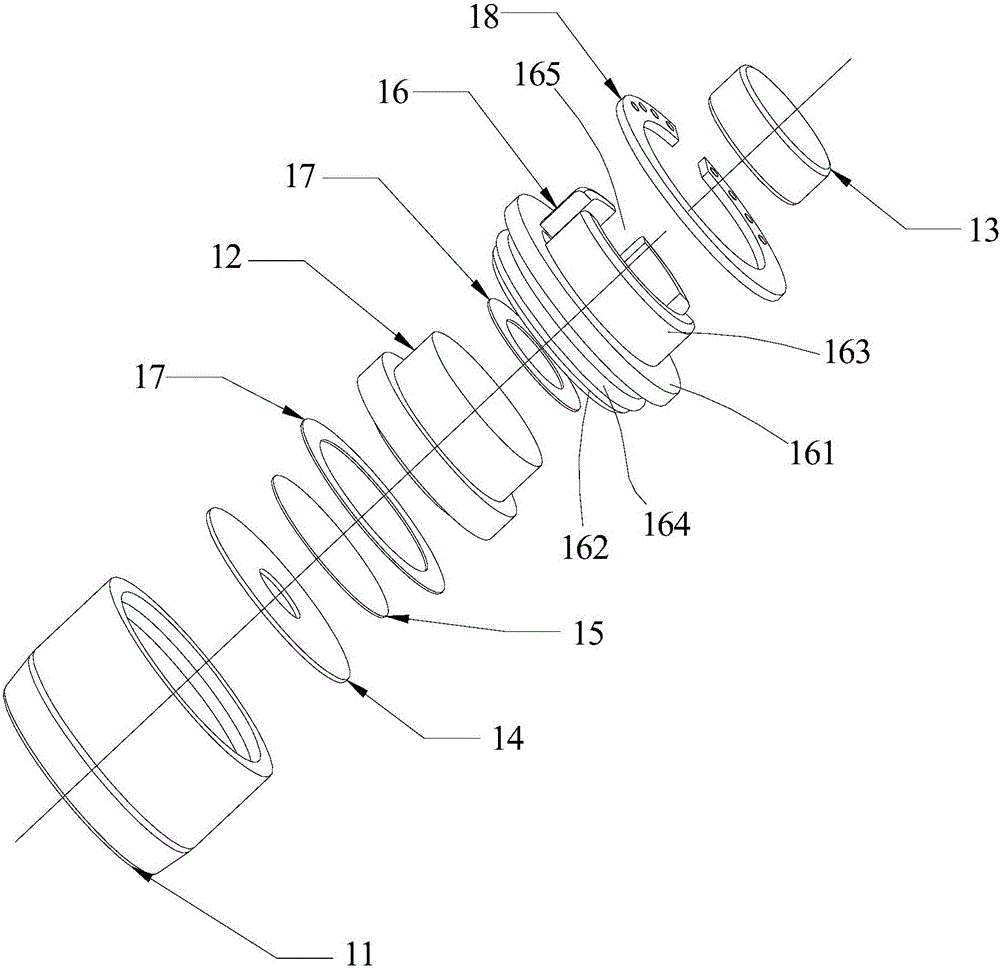

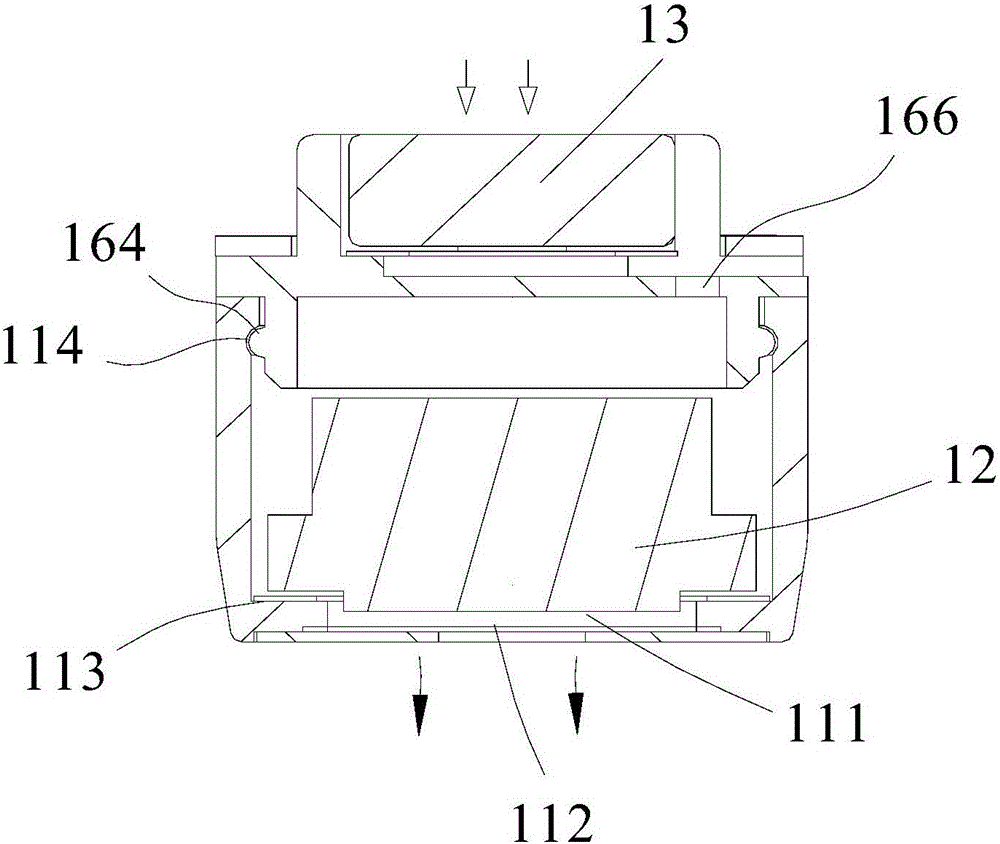

[0037] Such as figure 1 , figure 2 As shown, it is the first embodiment of the integrated sound-transmitting sensor of the present invention, including a hollow shell 11, a sound-emitting device 12, a sound-transmitting device 13, and the coaxial installation of the sound-emitting device 12 and the sound-transmitting device 13 in the hollow The installation structure of the integrated module is formed on the shell 11 . In this embodiment, the sound-generating device 12 is a speaker; the sound-transmitting device 13 is a microphone; of course, other devices can also be selected as required.

[0038] As shown in the figure, the hollow shell 11 is a cylindrical hollow shell 11, which is provided with a sound output channel 111 matching the sound output direction of the sound emitting device 12, and a sound output hole 112 connecting the sound output channel 111 to the outside. It can be understood that the shape of the hollow casing 11 can be designed into other arbitrary shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com