Structure for front part of vehicle body

A technology for the front and structure of the vehicle body, which is applied to the lower structure, upper structure, vehicle components, etc., can solve the problem of increasing the weight of the vehicle body, and achieve the effect of suppressing deformation and improving protection performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

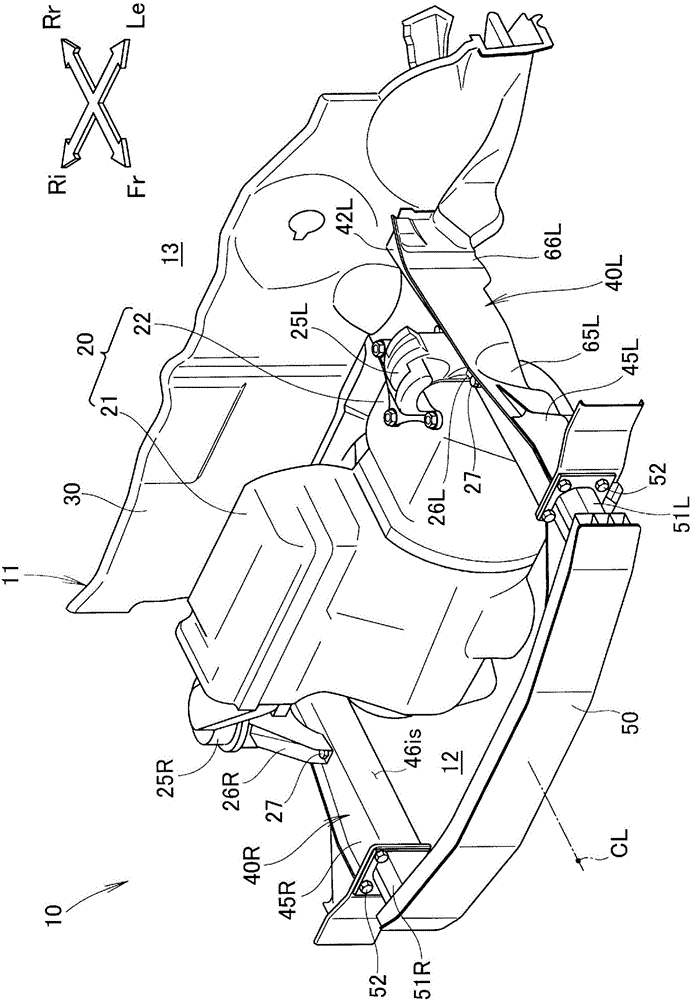

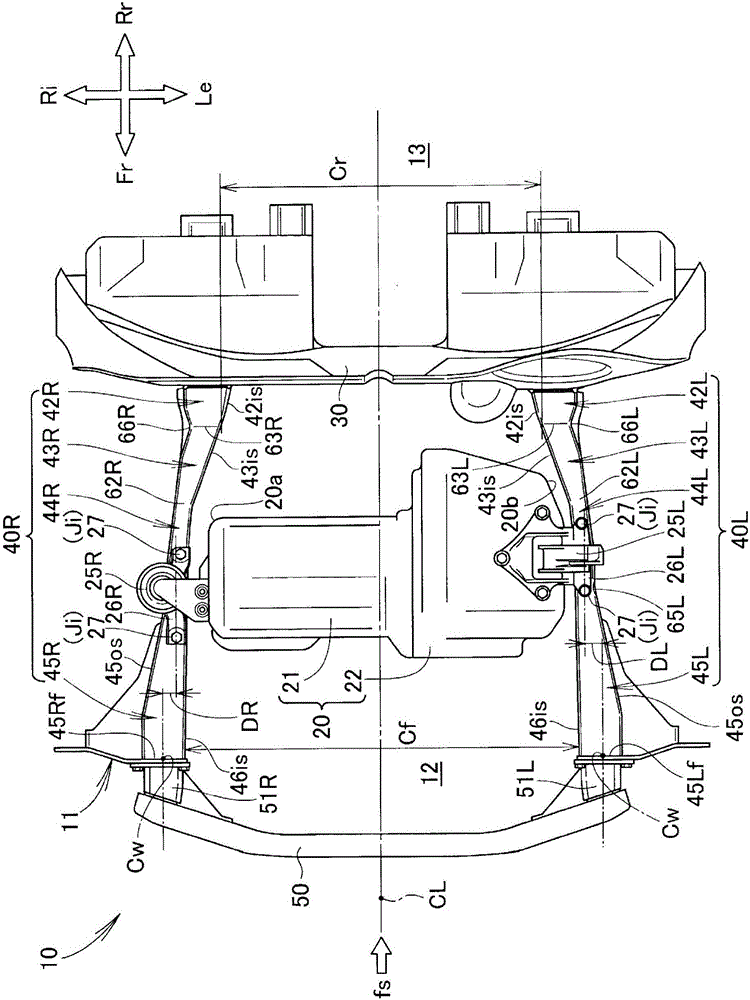

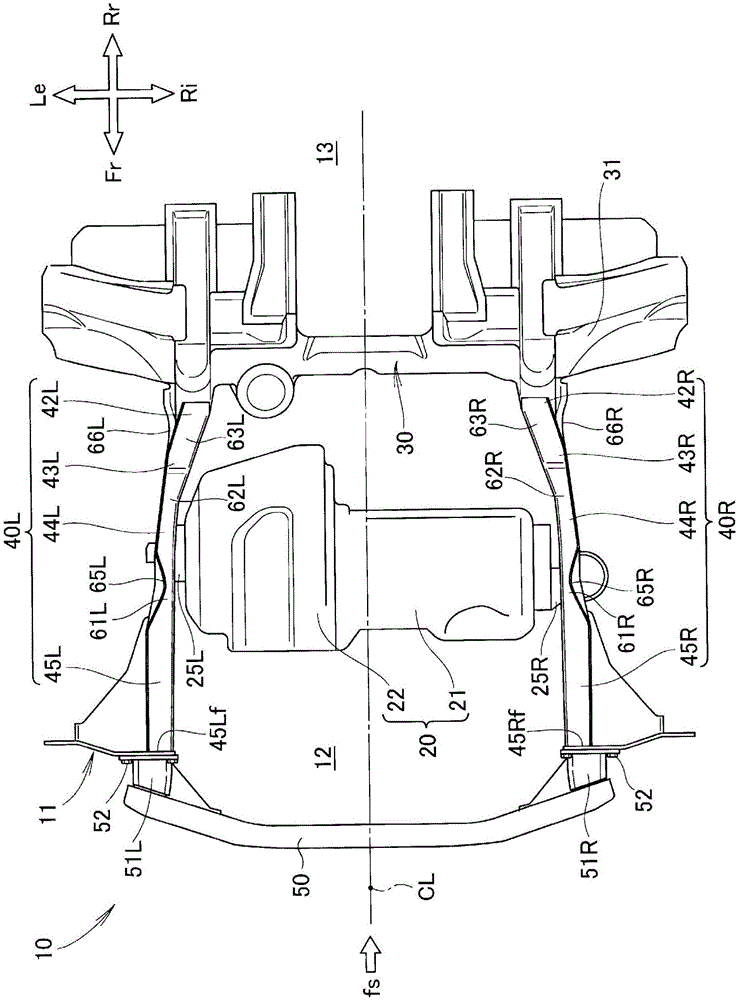

[0052] The vehicle body front structure of the embodiment will be described. Such as figure 1 and figure 2 As shown, vehicle 10 is, for example, a passenger car. A power unit compartment 12 at the front and a vehicle compartment 13 located directly behind the power unit compartment 12 are formed inside a vehicle body 11 of the vehicle 10 .

[0053] A power unit 20 is housed in the power unit chamber 12 . The power unit 20 is a so-called transverse type power unit in which an engine 21 and a transmission 22 are arranged in the vehicle width direction and combined with each other.

[0054] Such as Figure 1 to Figure 4 As shown, the vehicle body 11 is constituted by a monocoque body, and is formed in a left-right symmetrical shape with respect to a vehicle width centerline CL passing through the center of the vehicle 10 in the vehicle width direction and extending in the vehicle front-rear direction. The front portion of the vehicle body 11 includes a dashboard lower panel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com