Cathode suspension and vibration combined device of top vibration cleaning electrostatic dust collector

An electrostatic precipitator and cathode technology, which is applied in the direction of electrode conveying device, electrostatic separation, electrode cleaning, etc., can solve the problems of large investment equipment, heavy installation and maintenance workload, etc., and achieve good insulation performance, simple manufacture, and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

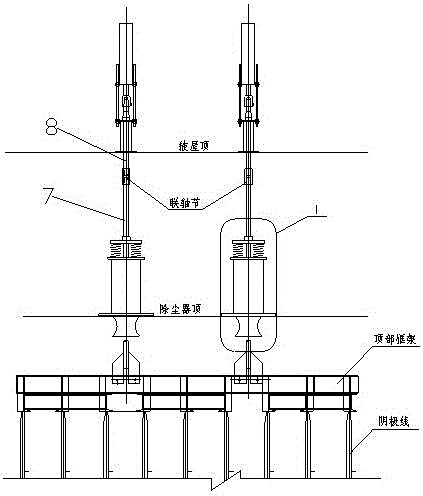

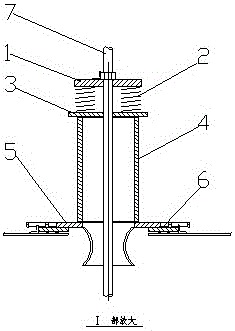

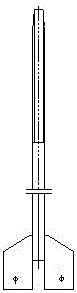

[0020] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the cathode wire is hung on the top frame of the cathode, and the draped roof support plate (6), adjustable base plate (5), insulator (4), and insulator cover are placed upwards in sequence on the top plate of the dust collector directly above the lifting point of the top frame Plate (3), spring (2), triple spring seat (1). The lower part of the high-pressure support rod (7) is connected to the lifting point of the top frame, and the rod body passes through the middle holes of the above-mentioned components respectively, and finally the upper surface of the triple spring seat (1) is screwed with the upper end thread of the high-pressure support rod (7) by a nut , thereby hanging the top frame of the cathode. The draped roof support plate (6) is used as the bottom plate of the lifting device, which can prevent the deformation of the top plate of the dust collector at the lifting point. The adjustable bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com