Electronic component test sorting equipment

A technology of electronic components and sorting equipment, which is applied in the field of electronic component testing and sorting equipment, can solve problems such as complex mechanism, complicated mechanism and transportation path, and increased complexity of transportation path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

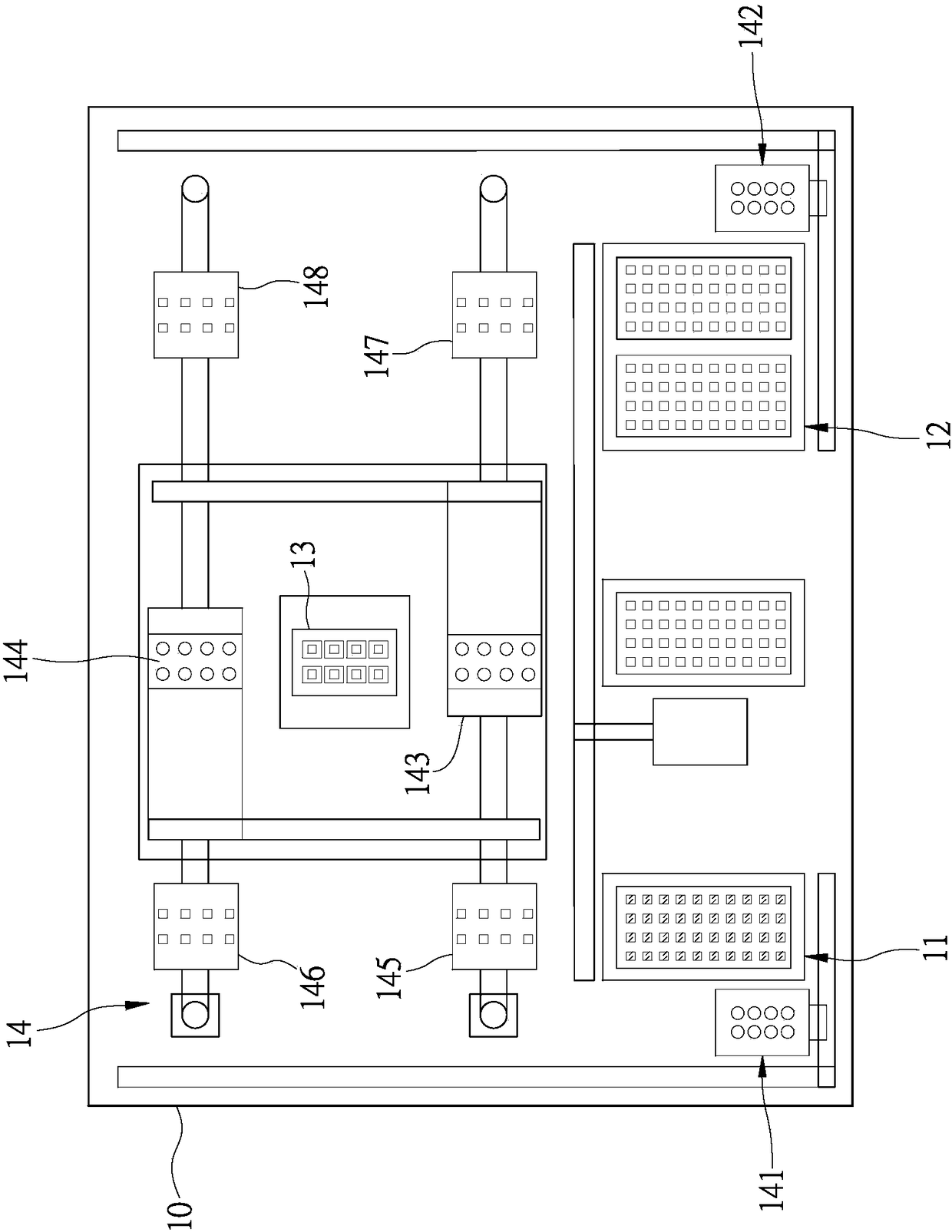

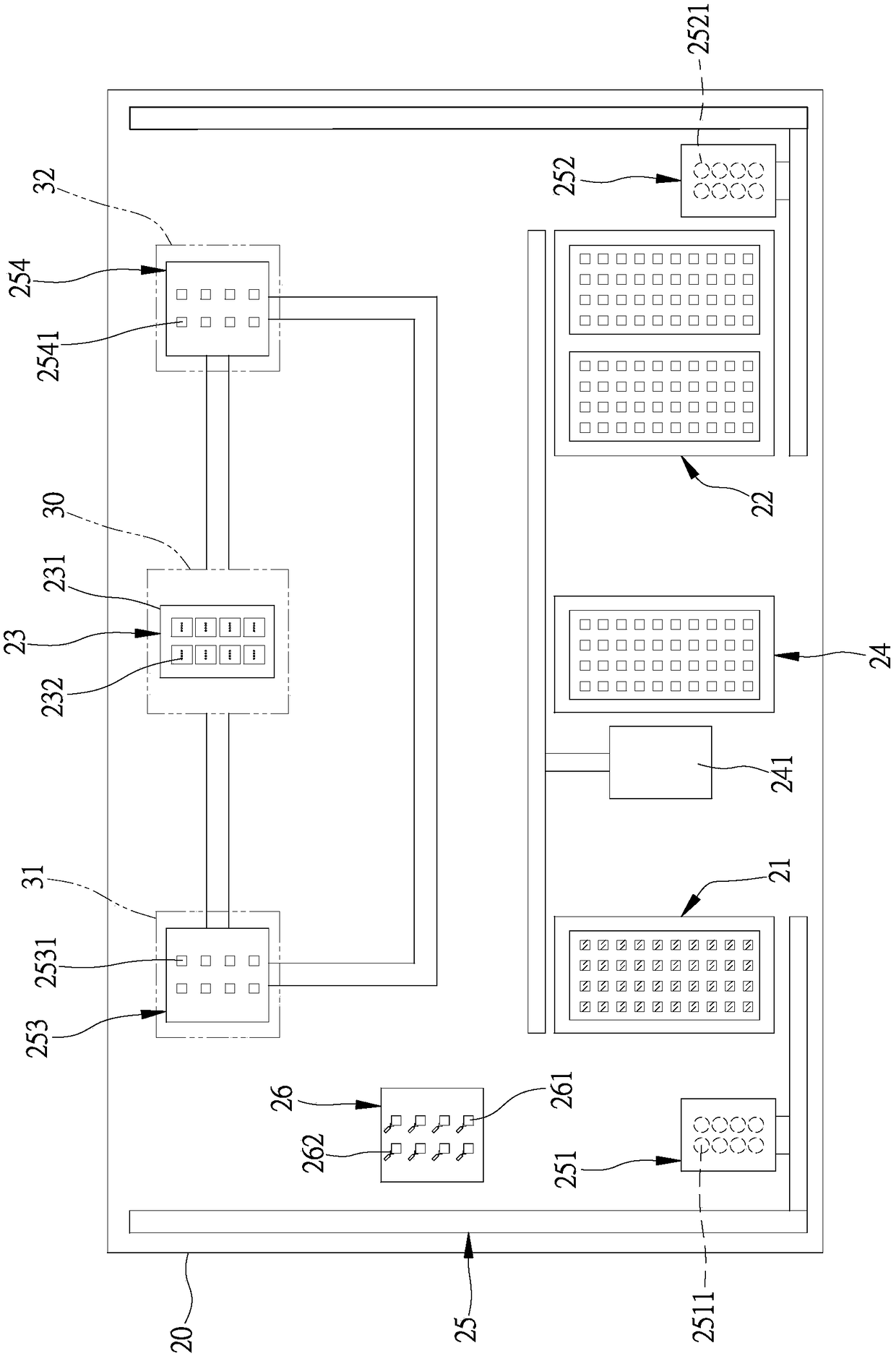

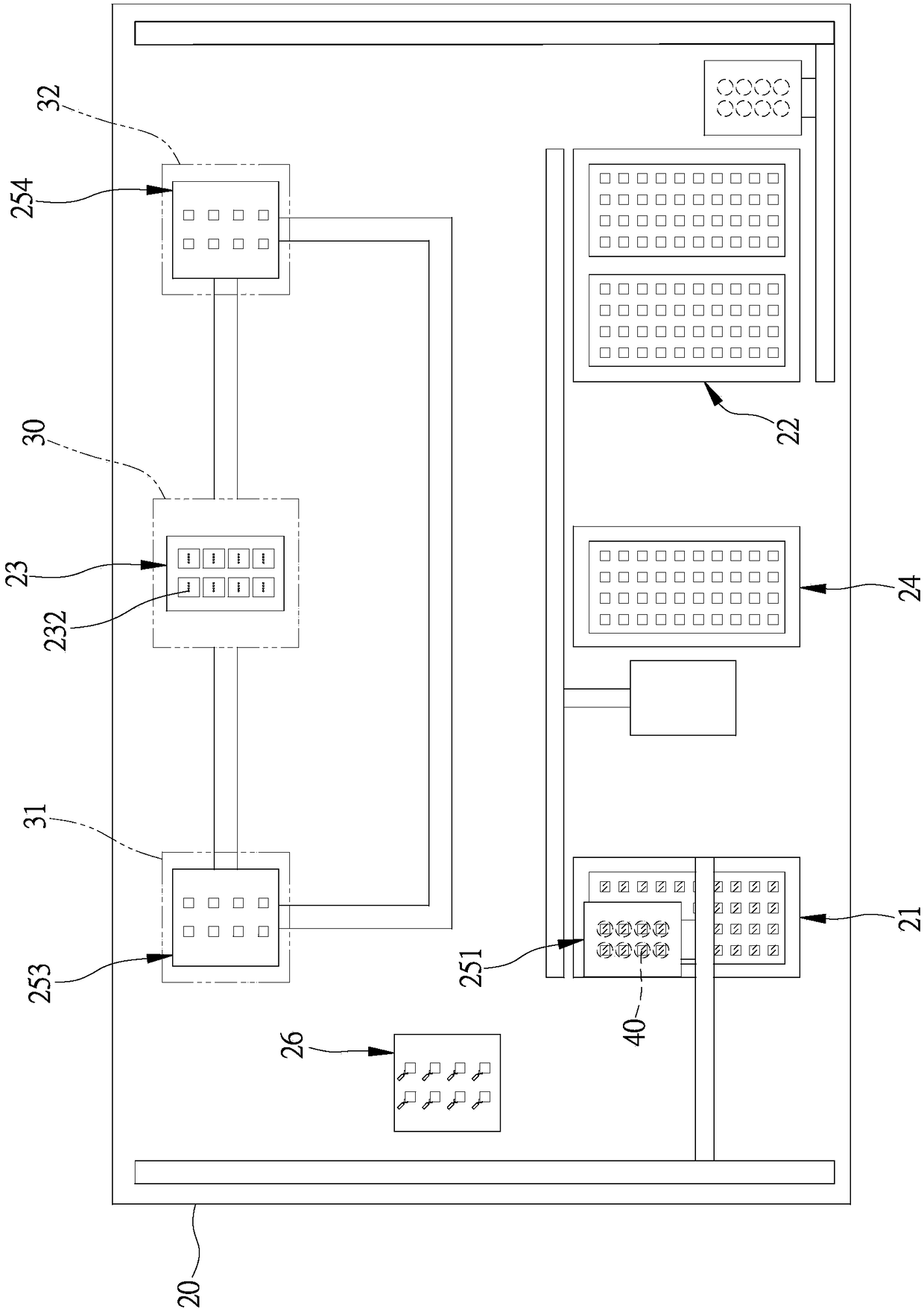

[0052] In order to make your review committee members have a further understanding of the present invention, the preferred embodiments are hereby given in conjunction with the drawings, and are described in detail as follows:

[0053] see figure 2 , the testing and sorting equipment of the first embodiment of the present invention, it is equipped with feeding device 21, material receiving device 22, testing device 23, empty plate device 24, conveying device 25 and alignment device 26 on machine platform 20, in addition In terms of area space, the machine 20 is provided with a test area 30, a first exchange area 31 located at the first side of the test area 30, and a second exchange area 32 located at the second side of the test area 30. The feeding device 21 Accommodate a plurality of electronic components to be tested with electrical contacts facing upwards, the receiving device 22 accommodates a plurality of tested electronic components of different grades, and the testing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com