Substrate disposing device and method

A substrate processing device and substrate technology are applied in the directions of transportation and packaging, conveyor objects, optics, etc., which can solve the problems of difficulty in adjusting the friction force between the substrate 90 and the rotating brush, difficulty in adjusting the angle, and poor cleaning, etc. Costs and maintenance costs, simplification of conveying routes, and the effect of preventing a reduction in cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

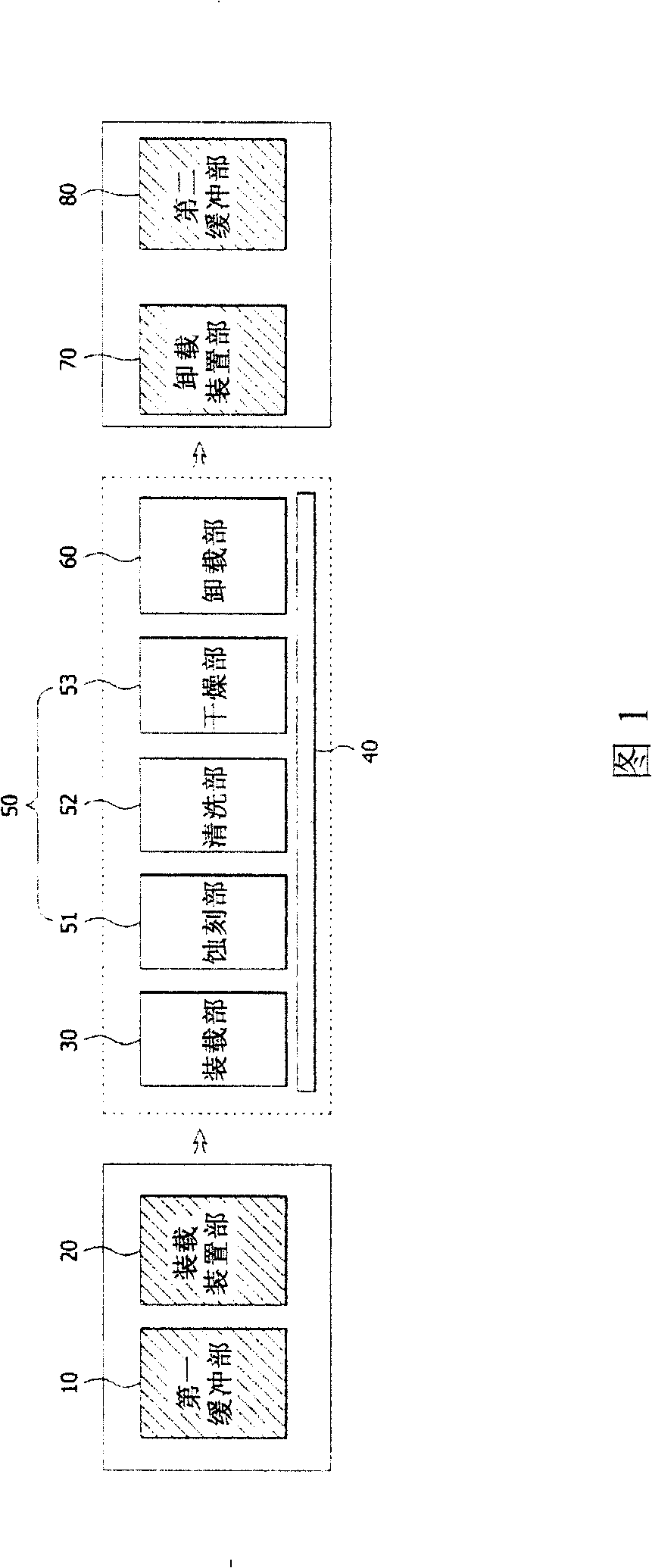

[0077] FIG. 6 is a block diagram of an embodiment of the substrate processing apparatus of the present invention; FIG. 7 is a simplified perspective view of an embodiment of the substrate processing apparatus.

[0078] As shown in the figure, an embodiment of the substrate processing apparatus of the present invention includes: a buffer unit 100 for temporarily storing substrates; a loading and unloading unit 300 for loading substrates transported from the buffer unit 100 by a transport device 200, or unloading (Unloading) the substrates that have completed surface treatment, and transport the processed substrates to the buffer unit 100 by the transport device 200; the first conveyor 400 transports the substrates loaded in the above-mentioned loading and unloading unit 300; the lifting unit 500, move the substrate transported by the first conveyor 400 downward, and load it on the second conveyor 600, so that the substrate is transported to the loading and unloading part 300 aga...

Embodiment 2

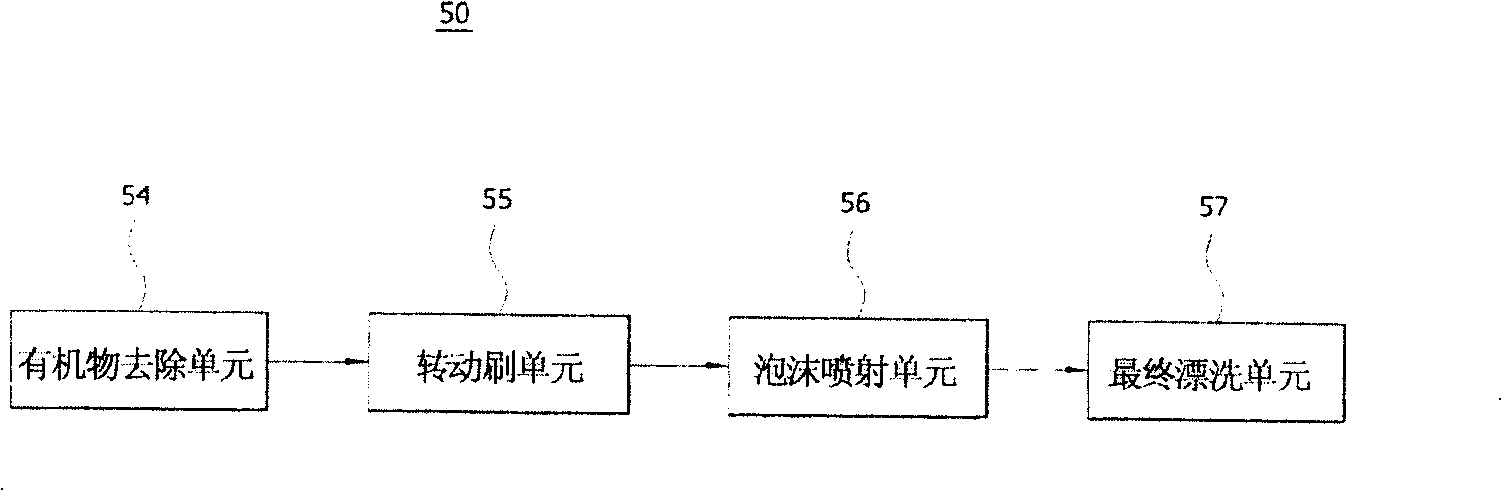

[0096] In the first embodiment above, the surface treatment unit 700 that directly processes the surface of the substrate is set to process the substrate conveyed by the second conveyor 600, but it may also be set to separate a part of the functions of the surface treatment unit 700 and It is arranged on the first conveyor 400 to perform related processing on the first conveyor 400 .

[0097] That is, like the first embodiment above, when the surface treatment unit 700 includes etching, cleaning, and drying the substrate, the etching unit 710 can be arranged on the first conveyor 400, and the substrate moved by the first conveyor 400 can be processed. After the etching process, the etched substrate is moved down and loaded onto the second conveyor 600 by the lifting part 500, and finally, when the substrate moved by the second conveyor 600 passes through the cleaning unit 720 and the drying unit 730 in sequence, Wash and dry.

[0098] By separating part of the functions of th...

Embodiment 3

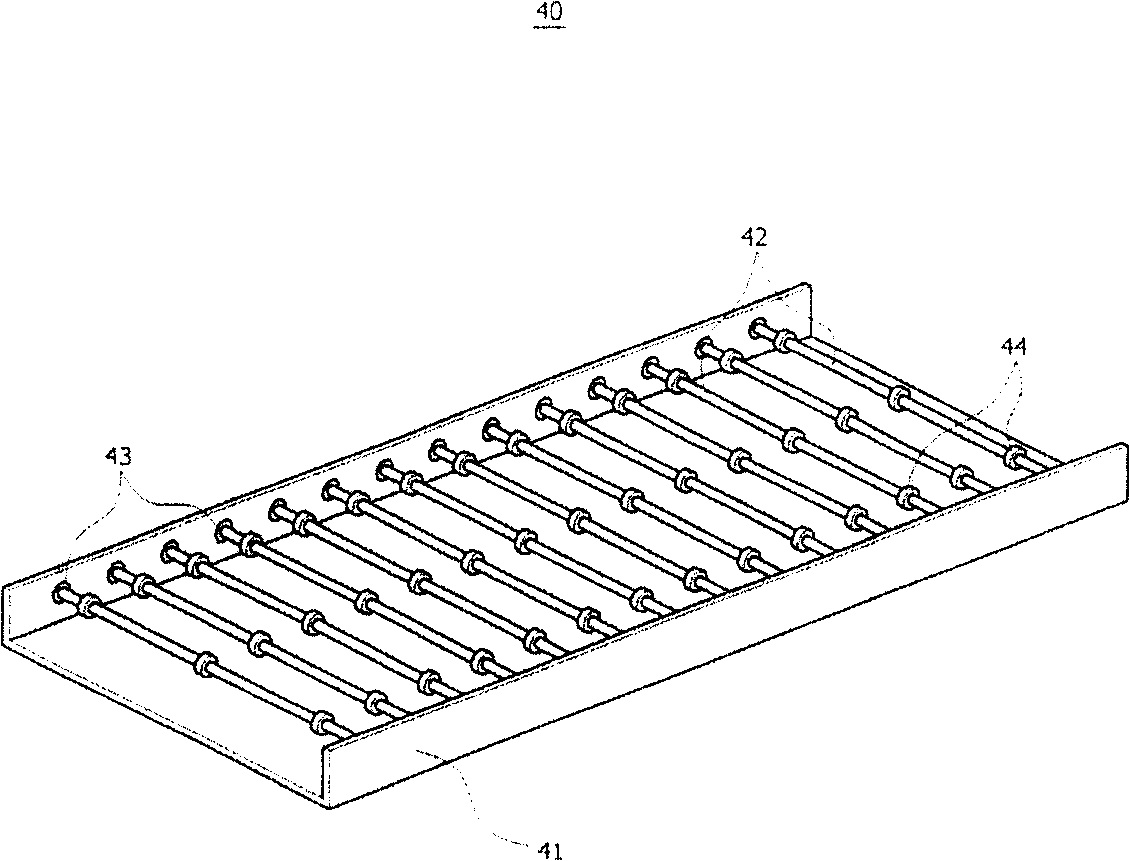

[0103] Figure 8 It is a perspective view of an embodiment of the above-mentioned second conveyor 600 .

[0104] As shown in the figure, the second conveyor 600 in the present invention includes: a supporting table 610 with an upwardly curved surface on both sides of the moving direction of the substrate; Bearings 630; a plurality of light weight shafts 620 rotatably coupled to the upwardly curved surface of the above-mentioned support platform 610 through the plurality of bearings 630;

[0105] Figure 9 is a cross-sectional view of one embodiment of the shaft 620 described above.

[0106] As shown in the figure, the shaft 620 of the second conveyor 600 in the present invention includes: a tubular body 621; an intermediate metal layer 622 attached to the outer peripheral surface of the above-mentioned body 621; layer 623 ; one end thereof is inserted into both sides of the body 621 , and the other end forms two ends 624 combined with the bearing 630 in the upward bending p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com