Large-span horizontal bright vertical hidden frame curtain wall system with short edge support and long edge without support and installation method thereof

A technology that is horizontally bright, vertically hidden, and has no support. It is applied to the processing of walls, building materials, and building components. It can solve the problems of being difficult to fully realize the architect's effect, high cost, and difficult to achieve the effect of no keel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

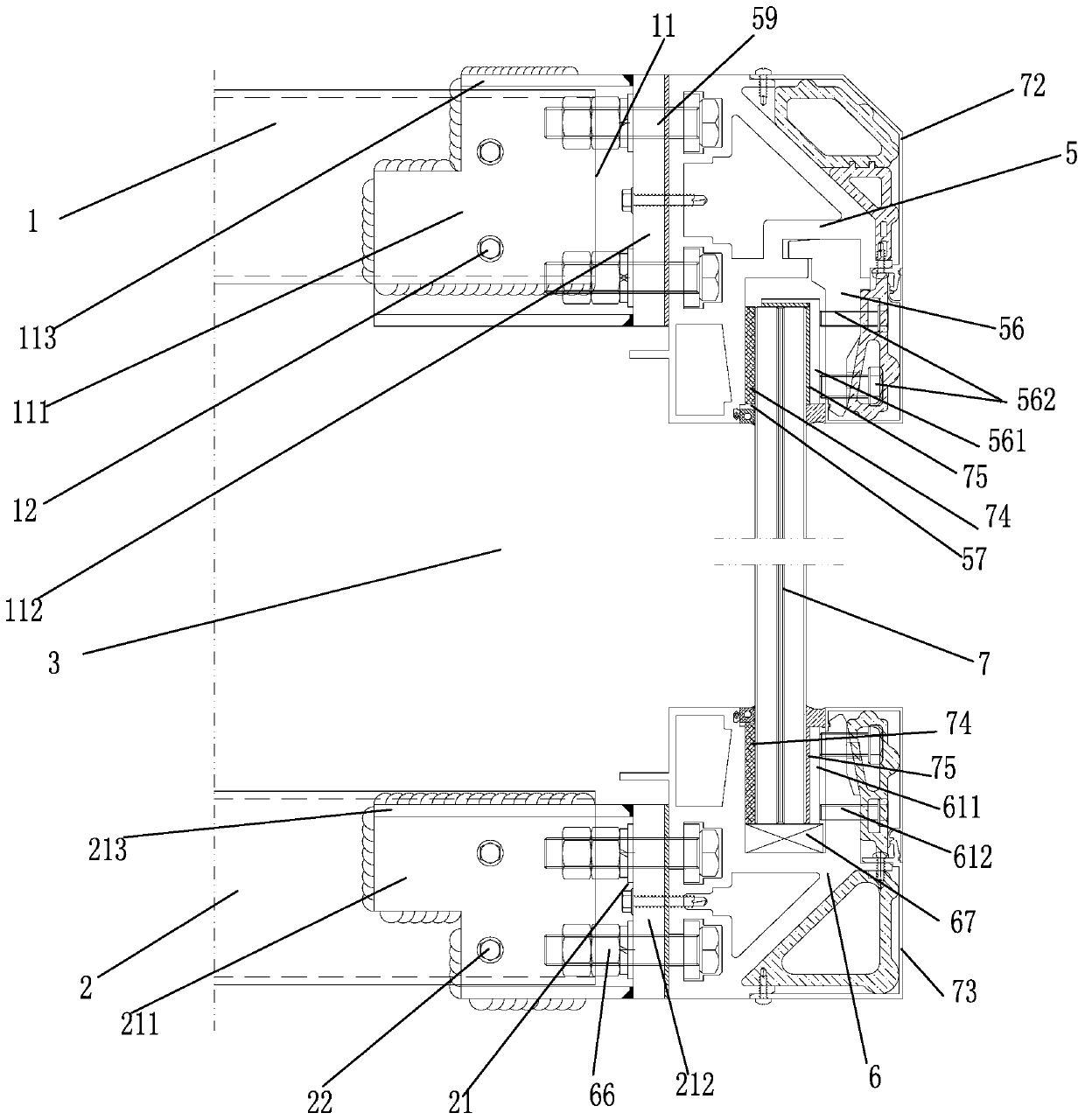

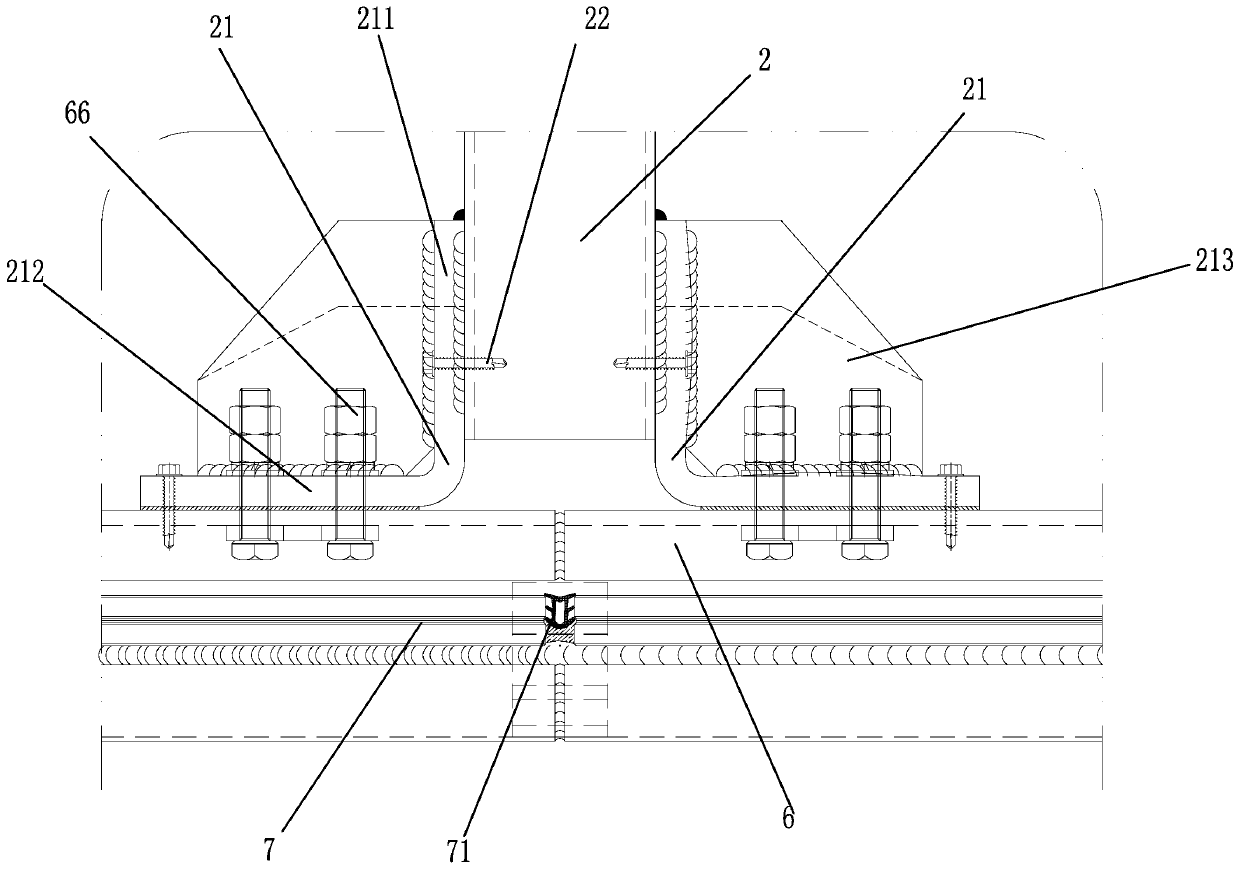

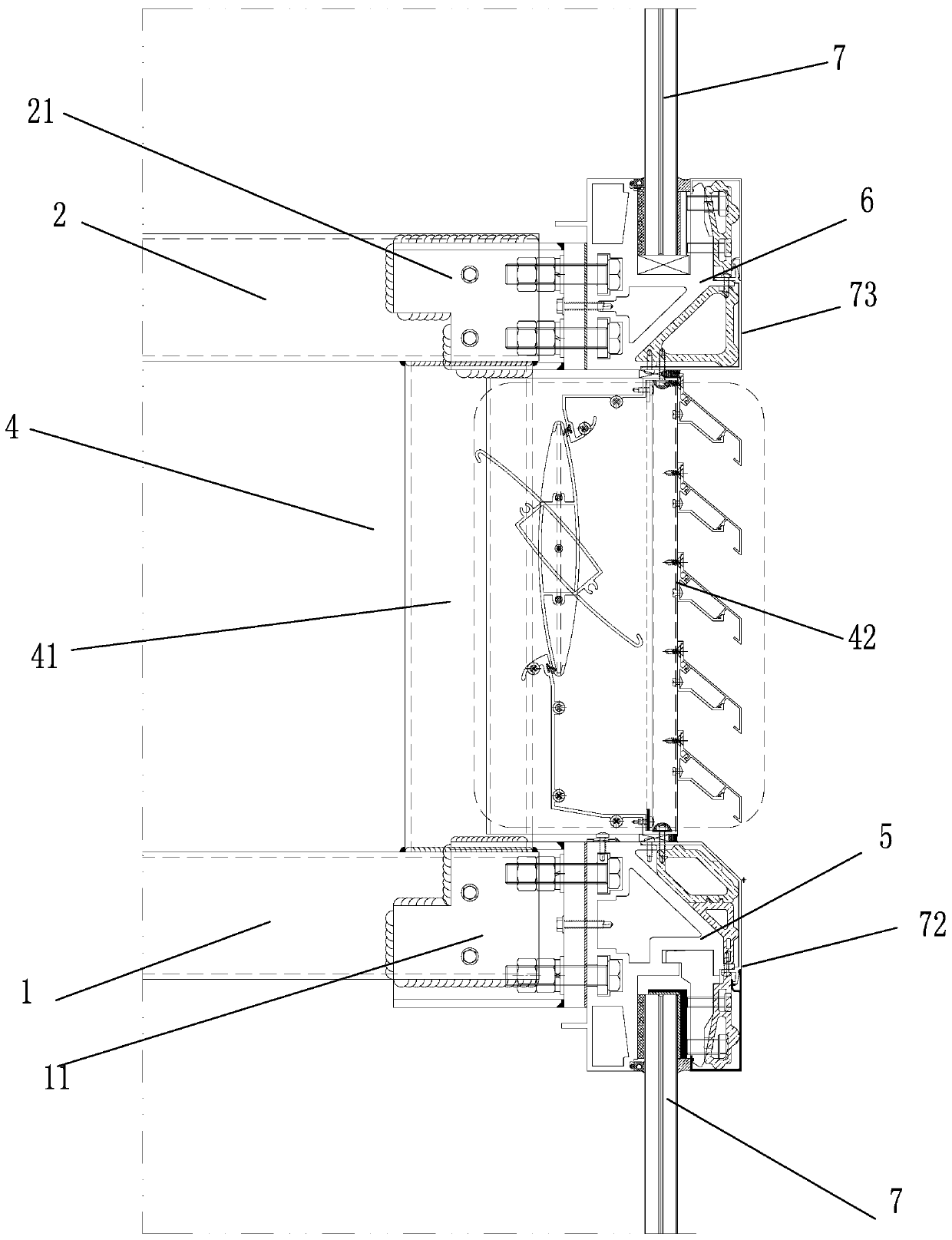

[0032] Such as Figure 1-Figure 5As shown, the present invention provides a large-span horizontal-exposed-vertical hidden frame curtain wall system with short sides supported and long sides unsupported, including several horizontal upper support beams 1 and lower support beams 2 . Each upper supporting beam 1 is fixed above the building bay 3, and each lower supporting beam 2 is fixed below the building bay 3. Between the adjacent building bays 3 is the building inter-floor 4 . The upper support beam 1 is symmetrically provided with L-shaped upper adapters 11 on both sides of the outer end, and the upper adapters 11 include a first upper plate 111 and a second upper plate 112 perpendicular to each other. The first upper plate 111 is welded to the upper support beam 1 and fixedly connected by first fixing screws 12 . An upper beam 5 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com