Connecting device for combined material plate spring and metal clamping plate

A composite material plate and connection device technology, which is applied in the direction of springs, springs/shock absorbers, leaf springs, etc., can solve problems that affect the life and normal use of parts, reduce the service life of leaf springs, and affect the application of composite leaf springs, etc. , to achieve the effect of improving NVH performance, reducing wear, reducing contact stress and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

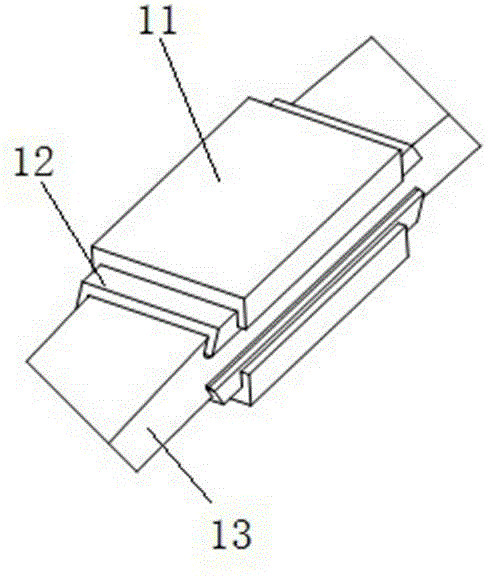

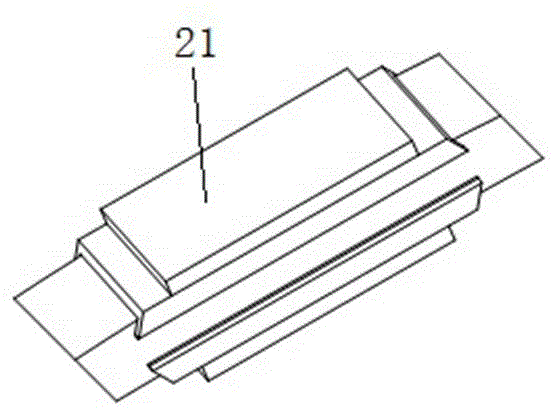

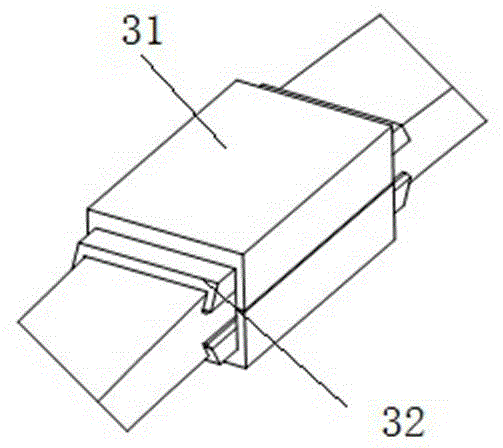

[0018] like figure 1 As shown, a connecting device of a composite material leaf spring and a metal splint includes a composite material leaf spring 13, a gasket 12 is arranged between the composite material leaf spring 13 and the metal splint 11, and the material of the flexible gasket is polyurethane, nylon , composite materials and other non-metallic flexible materials. The shape and thickness of the metal splint are not limited, such as figure 2 The shape of the middle metal splint 21 can also be a flat plate; as image 3 The shape of the middle metal splint 31 can completely wrap the composite material leaf spring and gasket in the width and thickness directions after the upper and lower splints are combined; the connection of the two splints can also be connected by a traditional metal leaf spring.

[0019] The shape of the gasket is not limited to figure 1 the shape shown. The gasket can be of equal thickness and width, or of variable thickness and width; the shape ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com