Gas jet gas cooling type superfine titanium alloy atomization device and gas jet gas cooling type spraying disk

An atomization device, titanium alloy technology, applied in the field of ultra-micro atomization and cooling production equipment, to achieve the effect of being conducive to accuracy, efficiency improvement, solving atomization and cooling and anti-reverse problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to enable the present invention to be better understood, necessary descriptions will be made below in conjunction with the accompanying drawings.

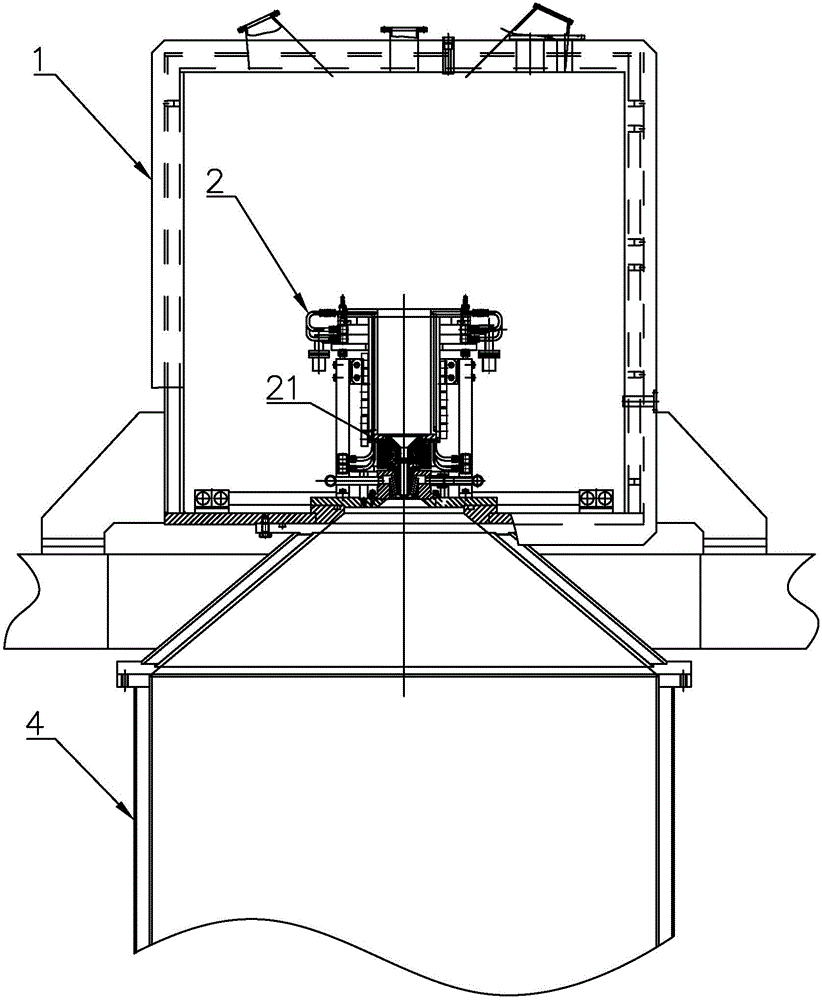

[0032] figure 1 The schematic diagram of the air-jet air-cooled ultrafine titanium alloy atomization device provided by the present invention includes:

[0033] Vacuum chamber 1 provides an oxygen-free environment;

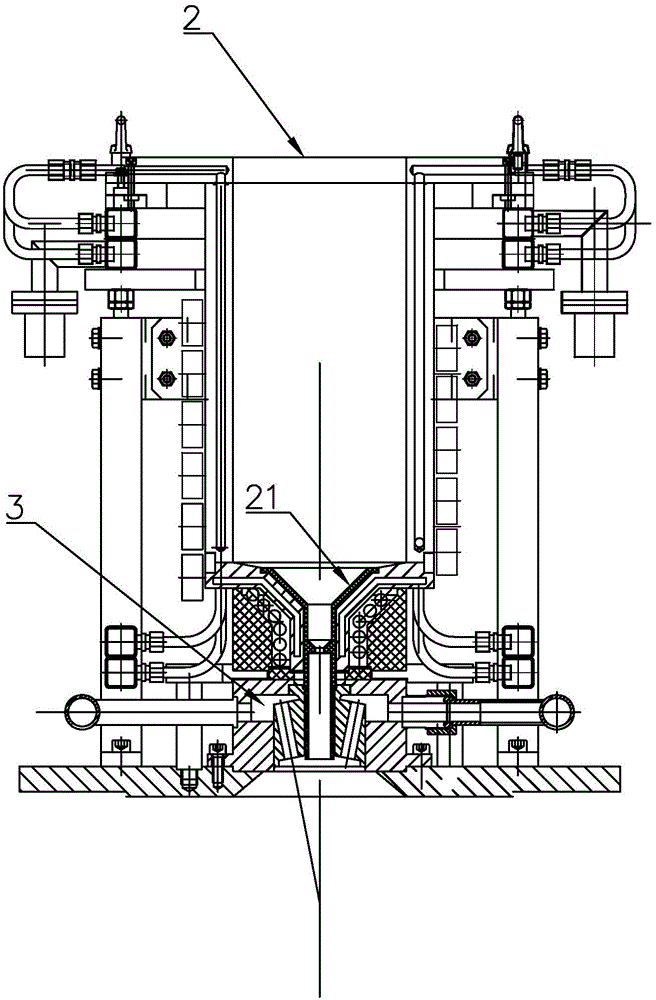

[0034] A melting furnace 2, which is arranged in the vacuum chamber 1, includes a crucible 21 for changing the titanium alloy from a solid state to a liquid state;

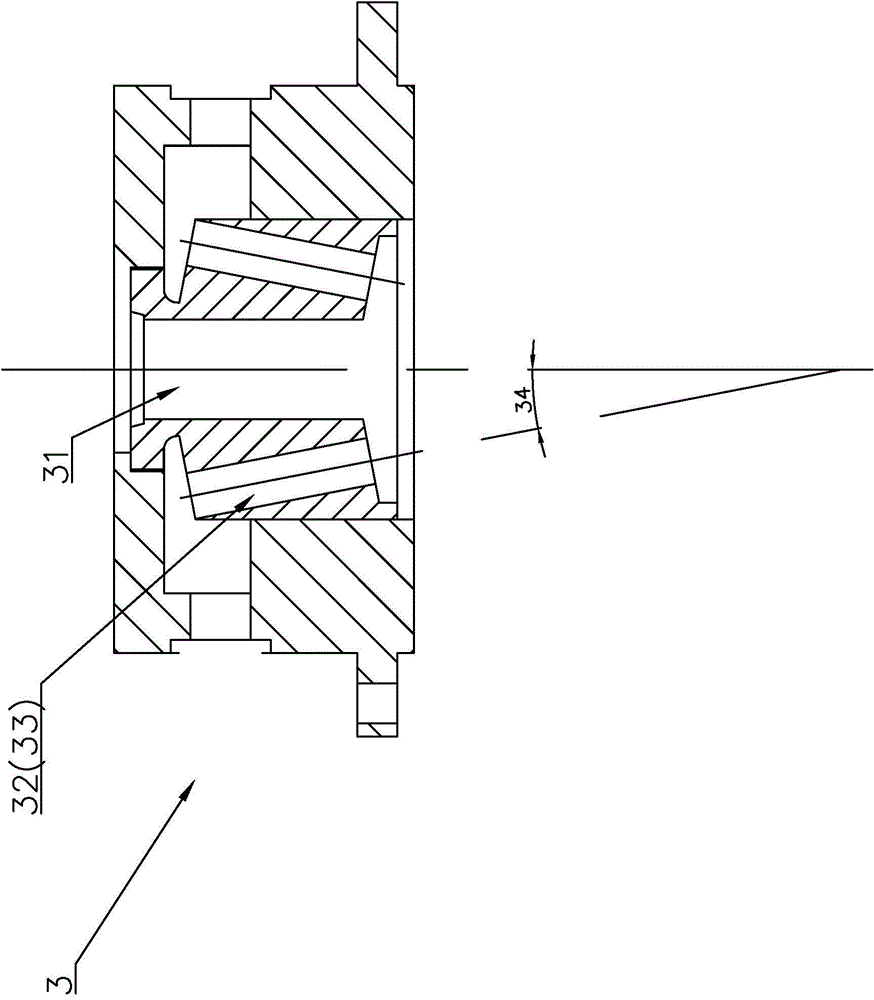

[0035] Air-jet air-cooled spray disc 3, combined with figure 1 , Figure 1A , figure 2 As shown, the center is provided with a vertical through hole 31, and the top of the through hole 31 is connected with the crucible 21 in the melting furnace 2 to pass through for the liquid titanium alloy; Also around the through hole 31 is only provided with a circle of slanted holes 32 distributed at intervals, and a Laval nozzle 33 with the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com