Antibacterial real silk scarf and manufacturing method

A scarf and silk technology, applied in textiles and papermaking, fiber processing, animal fibers, etc., can solve the problems of chemical properties, human health hazards, etc., and achieve the effect of preventing damage and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

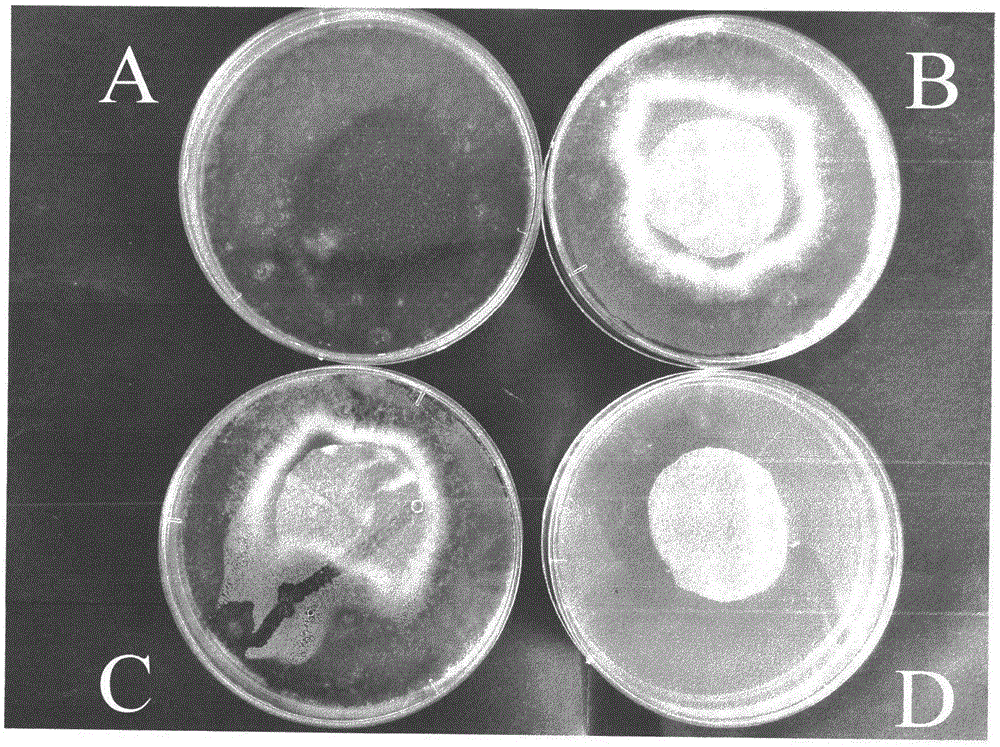

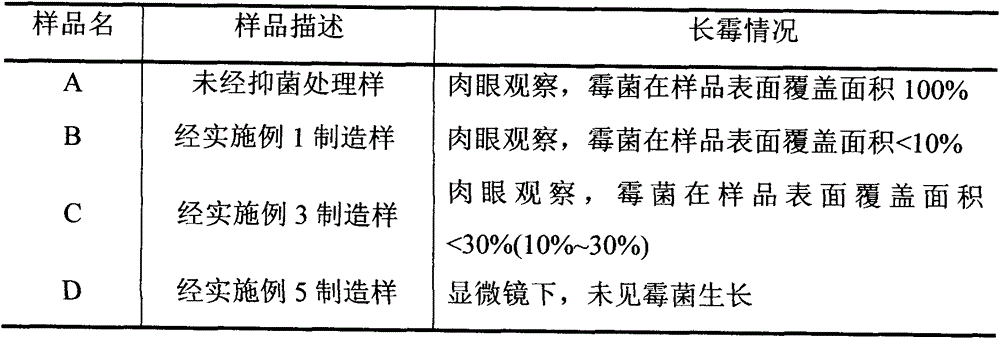

Image

Examples

Embodiment 1

[0019] Selection composition and content (percentage by weight) are: the natural antibacterial material of 40% Moringa seed, 20% Sophora flavescens, 10% Scutellaria baicalensis, 20% Phellodendron Phellodendron and 10% Kochia chinensis, adopts dipping method to manufacture antibacterial Mycosilk scarf. First destain the silk scarf and hang to dry. Then the silk scarf product with clean surface is placed in the natural bacteriostatic material working solution for dipping treatment, the concentration of the working solution is controlled at 0.1% (o.w.f), and the dipping time is controlled at 65 minutes. Finally, the silk scarf is dried at a low temperature, and the drying temperature is controlled at 75°C.

Embodiment 2

[0021] The natural antibacterial material selected is the same as Example 1, and the manufacturing method adopted is also basically the same as Example 1, except that the concentration of the working solution is controlled at 1% (o.w.f), and the soaking time is controlled at 30 minutes. The drying temperature was controlled at 50°C.

Embodiment 3

[0023] The natural bacteriostatic material selected is the same as Example 1, except that the antibacterial silk scarf is manufactured by spraying. First destain the silk scarf and hang to dry. Then the natural bacteriostatic agent working liquid that concentration is 5% (o.w.f) utilizes sprayer to evenly spray on the front and back surfaces of the pure silk scarf products that the surface is clean. Repeated spraying 5 times. Finally, the silk scarf is dried at low temperature, and the drying temperature is controlled at 50°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com