Pre-wetting device for automatic ultrasonic detection

A technology of ultrasonic testing and pre-humidifier, which is applied in the direction of material analysis, instruments, and measuring devices using sonic/ultrasonic/infrasonic waves, which can solve inaccurate testing results, affect ultrasonic testing results, and affect equipment testing accuracy and service life. problems, to ensure the coupling effect, prolong the service life, and improve the detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

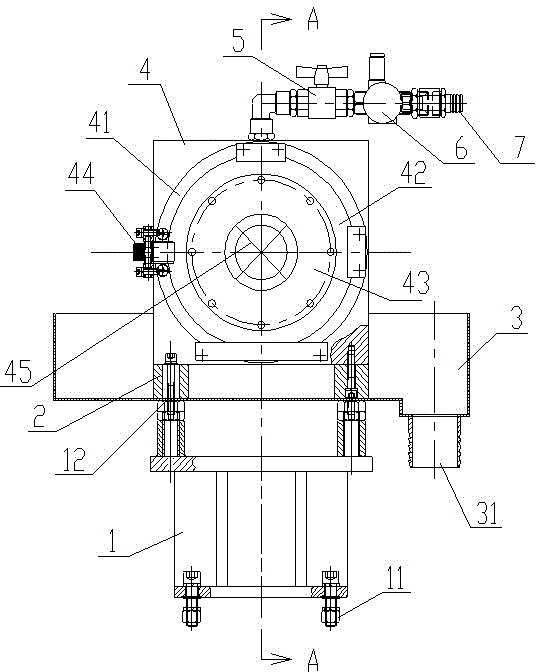

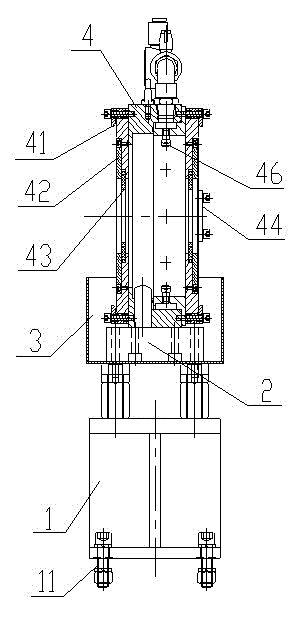

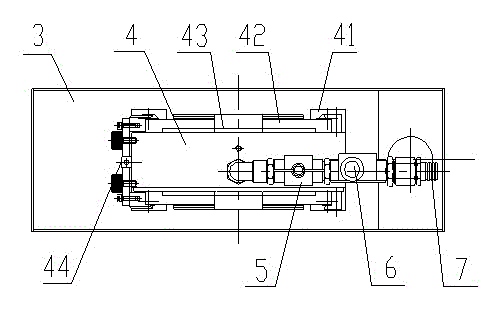

[0018] Example figure 1 , figure 2 with image 3 As shown, the pre-humidifier for automatic ultrasonic detection of the present invention includes a base 1, a bottom plate 2, a collection tank 3, a box body 4, an annular pressure plate 41, an annular sealing plate 42, a scraper plate 43, a stop valve 5, and a fluid control valve. 6. Quick connector 7 and several nozzles 46, the collection tank 3 is arranged on the top surface of the base 1, the bottom plate 2 is located in the collection tank 3 and fixed to the bottom plate 2 and the collection tank 3 by bolts The top surface of the base 1, the box body 4 is arranged on the top surface of the bottom plate 2 through bolts, the bottom surface of the box body 4 is open and communicates with the collection tank 3, and the top surface, the front and the back of the box body 4 are respectively provided with Through holes, the through holes on the top surface of the box body 4 are sequentially connected to the shut-off valve 5, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com