Wafer Thinning Methods

A wafer and ring-shaped technology, applied in the manufacturing of electrical components, circuits, semiconductor/solid-state devices, etc., can solve the problems of low production efficiency, easy warpage deformation, fragile wafers, etc., to achieve a wide range of tolerance, The effect of ensuring efficiency, reducing process difficulty and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

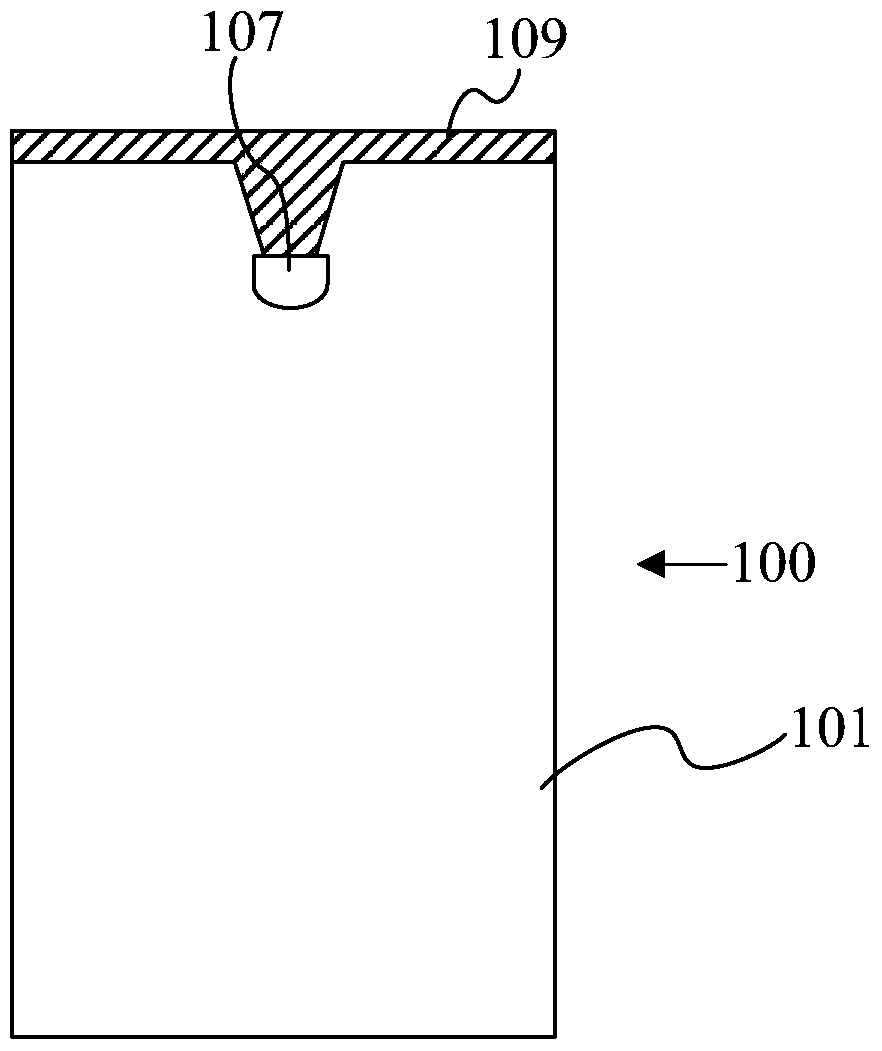

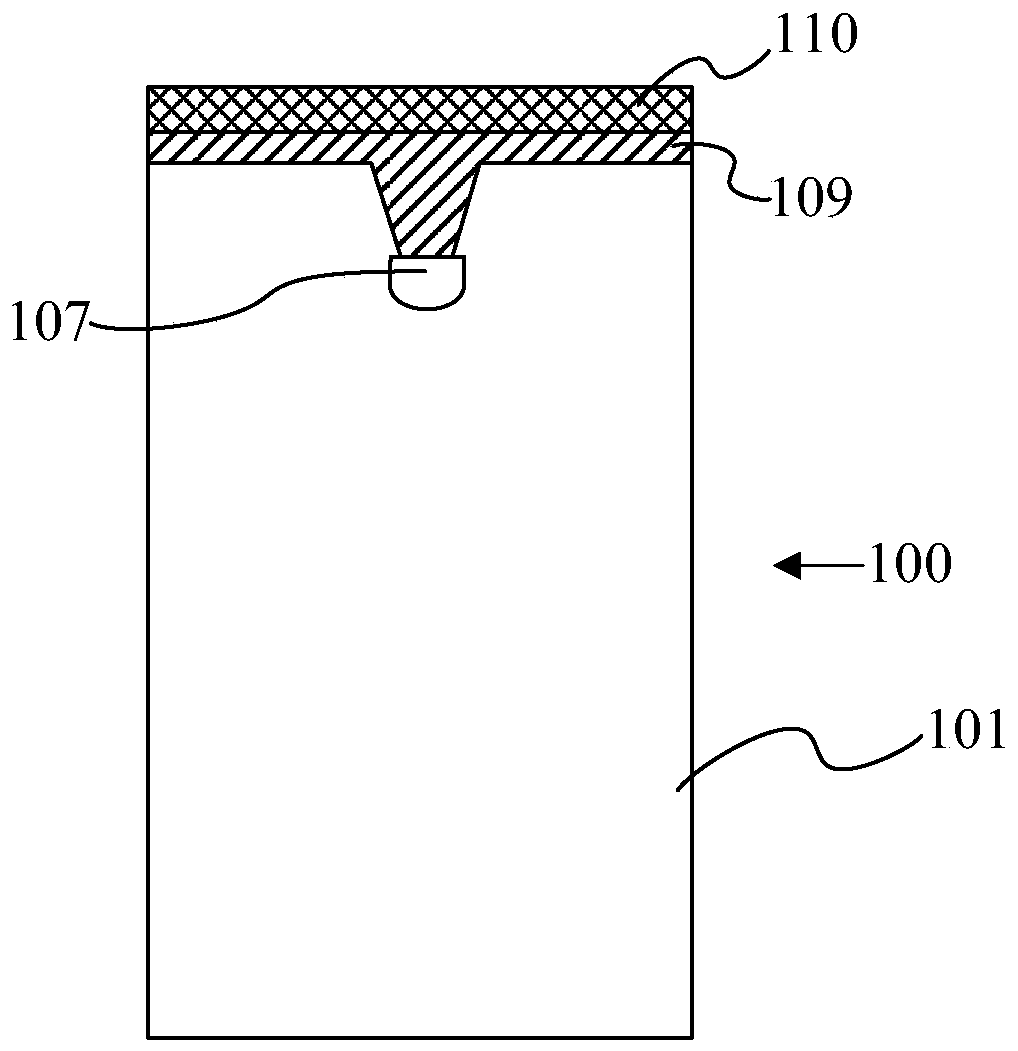

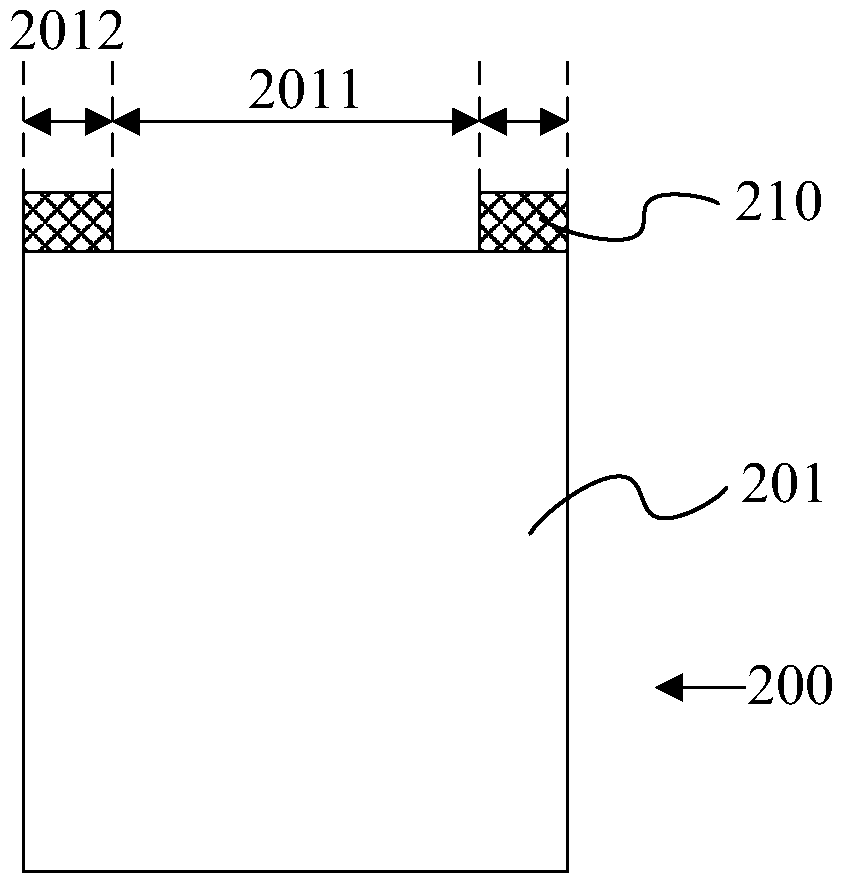

[0045] In order to reduce cracks or warping of the wafer when the wafer is thinned, in the prior art, the wafer to be thinned is adhered to a pad wafer by glue in advance before the wafer is thinned, and then A thinning process is performed on the tape thinned wafer attached to the pad wafer. The thinned wafer is then removed from the backing wafer for use. However, this method has a small range of temperature tolerance, especially high temperature, because the glue may start to decompose or soften at a slightly higher temperature (higher than 100 degrees Celsius), which will lead to thinned wafers and The gasket wafers cannot be tightly fixed, which may cause cracks or warping of the wafer to be thinned during the thinning process.

[0046] At the same time, in order not to make the temperature too high in the prior art, the ambient temperature of the wafer has to be kept within a certain temperature. But this will affect the progress of other processes, bring troubles to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com