Safe lifting platform

A lifting platform and platform technology, applied in the direction of operating tables, tables with variable table heights, medical science, etc., can solve problems such as table damage, safety hazards, and low product safety, so as to improve accuracy, safety, avoid damaging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0045] The difference between this embodiment and the first embodiment is that a buffering component is provided between the triggering component and the motor.

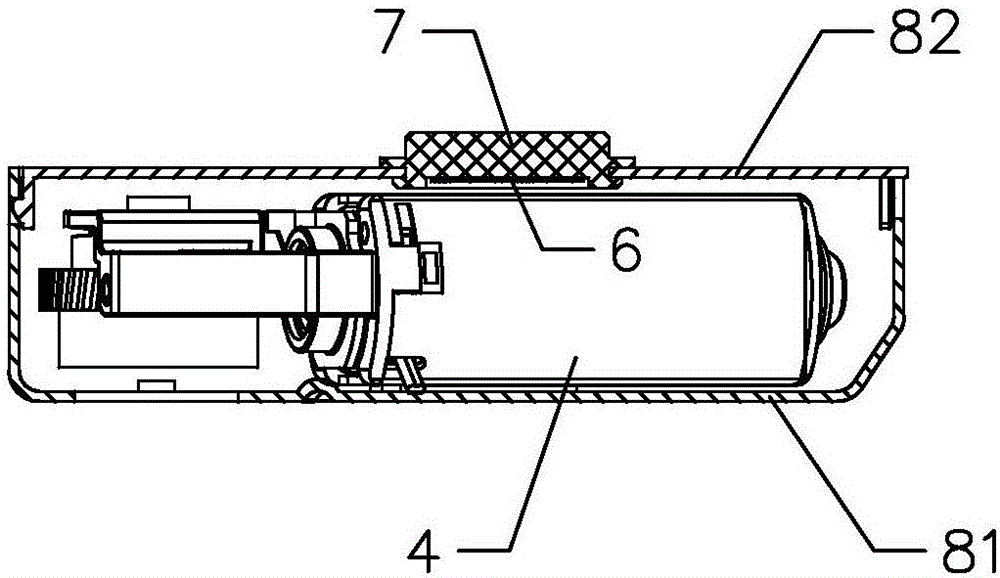

[0046] Such as Figure 5 , 6 As shown, a buffer 9 is provided between the triggering member 7 and the surface of the motor 4. The buffer 9 is a soft rubber pad, specifically a silicone pad, and the buffer 9 is fixed to the surface of the motor 4 by pasting.

[0047] The advantage of this embodiment is that by providing a buffer between the triggering member and the surface of the motor, when the triggering member is subject to a large collision, the sensing element is guaranteed not to be damaged, and the service life of the sensing element is increased.

[0048] It can be understood that the cushioning member is a rubber pad or a foam pad or a sponge pad or a spring.

[0049] It is understandable that the buffer member is fixed to the lower surface of the trigger member by pasting.

[0050] It can be understood that the buffe...

Embodiment 3

[0052] The difference between this embodiment and the first embodiment is that the triggering component is installed in a different way.

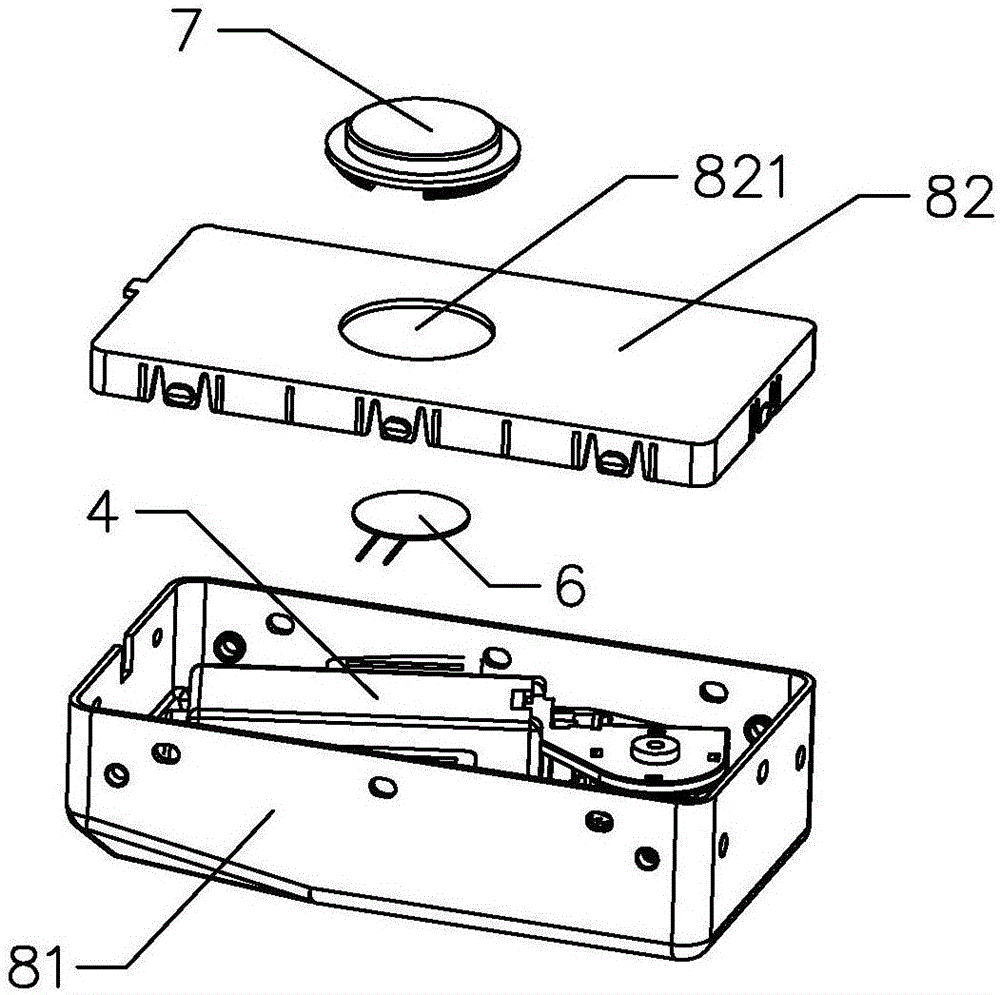

[0053] Such as Figure 7 , 8 As shown, the trigger 7 is attached to the upper surface of the cover 82, the sensing element 6 is provided on the lower surface of the cover 82 corresponding to the trigger 7, and the trigger 7 is fixed to the upper surface of the cover 82 by pasting.

[0054] The advantage of this embodiment is that it facilitates the installation of the trigger and the sensing element, and improves the sensitivity of the trigger and the sensing element, thereby improving the accuracy of detection; at the same time, the trigger is fixed on the upper surface of the cover by pasting, Easy to install and fix and reliable.

[0055] It is understandable that there is a buffer between the sensing element and the motor, and the buffer is a silicone pad, a rubber pad, a foam pad, a sponge pad, or a spring.

Embodiment 4

[0057] The difference between this embodiment and the first embodiment is that the trigger is different.

[0058] In this embodiment, the trigger 7 and the cover 82 of the support shell 8 are integrally formed, the sensing element 6 is attached to the lower surface of the cover 82, the sensing element 6 is fixed to the lower surface of the cover 82 by pasting, and the sensing element 6 passes The deformation of the cover 82 is used to detect whether the platform collides, so as to realize the anti-collision function of the lifting platform.

[0059] The advantage of this embodiment is that by integrally forming the trigger part and the cover plate, the parts of the lifting platform are reduced, the cost is reduced, the processing and assembly are reduced, and the production efficiency is improved.

[0060] It is understandable that there is a buffer between the sensing element and the motor, and the buffer is a silicone pad, a rubber pad, a foam pad, a sponge pad, or a spring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com