Crop straw crushing and sorting integrated device and method

The invention relates to a technology for crop straws and straws, which is applied in the field of crop straw man-made panels, and can solve the problems of affecting the bonding strength and surface quality of man-made panels, reducing the utilization rate of straw raw materials, and low screening efficiency, so as to improve the sorting effect and improve the sorting efficiency. The effect of good effect and improved appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

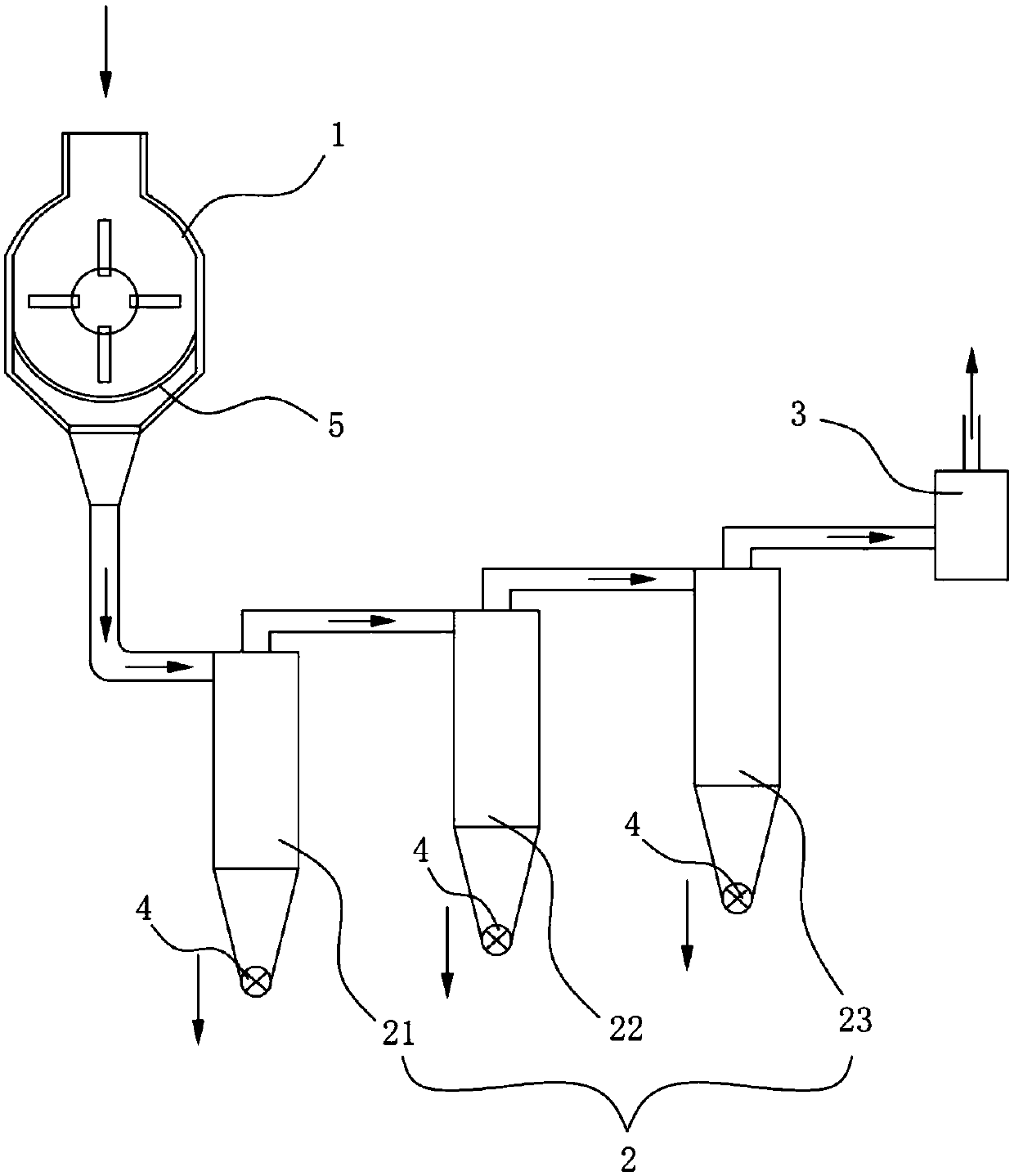

[0030] like figure 1As shown, an embodiment of the crop straw crushing and sorting integrated device of the present invention includes a straw crusher 1 and a centrifugal separator group 2 . Wherein, a screen 5 is provided directly under the straw crusher 1; the centrifugal separator group 2 includes a first centrifugal separator 21, a second centrifugal separator 22 and a third centrifugal separator 23 connected in sequence, and the first centrifugal separator The lower parts of the device 21, the second centrifugal separator 22 and the third centrifugal separator 23 are all provided with a one-way discharge valve 4. The first centrifugal separator 21 is connected to the bottom of the straw crusher 1 through an air pipe, and the third centrifugal separator 23 is connected to the induced draft fan 3 through an air pipe. The straw crusher 1 is connected with the sorting device (centrifugal separator group 2). After the straw is crushed by the straw crusher 1, the straw is init...

Embodiment 2

[0033] An embodiment of the crop straw crushing and sorting integrated method of the present invention comprises the following steps:

[0034] (1) Start the induced draft fan 3, the one-way discharge valve 4 at the bottom of the three centrifugal separators and the driving motor of the straw crusher 1 in sequence.

[0035] (2) The straw is sent into the straw crusher 1 from the upper feed port of the straw crusher 1 with a power of 90kW according to the conveying speed of 1.5 tons per hour; To the screen cloth 5 that mesh diameter is 8mm; Under the effect of negative pressure, rice straw fragment enters the first centrifugal separator 21 that cylindrical body diameter is 2000mm by the mesh of screen cloth 5 and air duct; The large-grain straw fragments (below 10 mesh), sand grains, rice grains, and straw knots that cannot be used for the production of straw-based panels will be separated together under the action of the first centrifugal separator 21. The power at the bottom o...

Embodiment 3

[0045] An embodiment of the crop straw crushing and sorting integrated method of the present invention comprises the following steps:

[0046] (1) Start the induced draft fan 3, the one-way discharge valve 4 at the bottom of the three centrifugal separators and the driving motor of the straw crusher 1 in sequence.

[0047] (2) The wheat straw is sent into the straw crusher 1 from the upper feed port of the straw crusher 1 with a power of 75kW according to the conveying speed of 1.2 tons per hour; To the screen cloth 5 that mesh diameter is 10mm; Under the effect of negative pressure, the wheat straw scrap enters the first centrifugal separator 21 that cylindrical device body diameter is 1800mm by the mesh of screen cloth 5 and air duct; Under the action of the large particle wheat straw debris (below 10 mesh) that can not be used for wheat straw wood-based panel production and sand grain, wheat grain, wheat straw knot etc. are separated together, the power that is positioned a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap