Thread oil automatic applicator

A threaded and automatic technology, applied in the direction of spraying devices, liquid spraying devices, etc., can solve the problems of low work efficiency, short service life of drilling tool threads, slow operation progress, etc., to reduce labor intensity of workers, improve service life, The effect of saving working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing of description, the present invention is described in further detail:

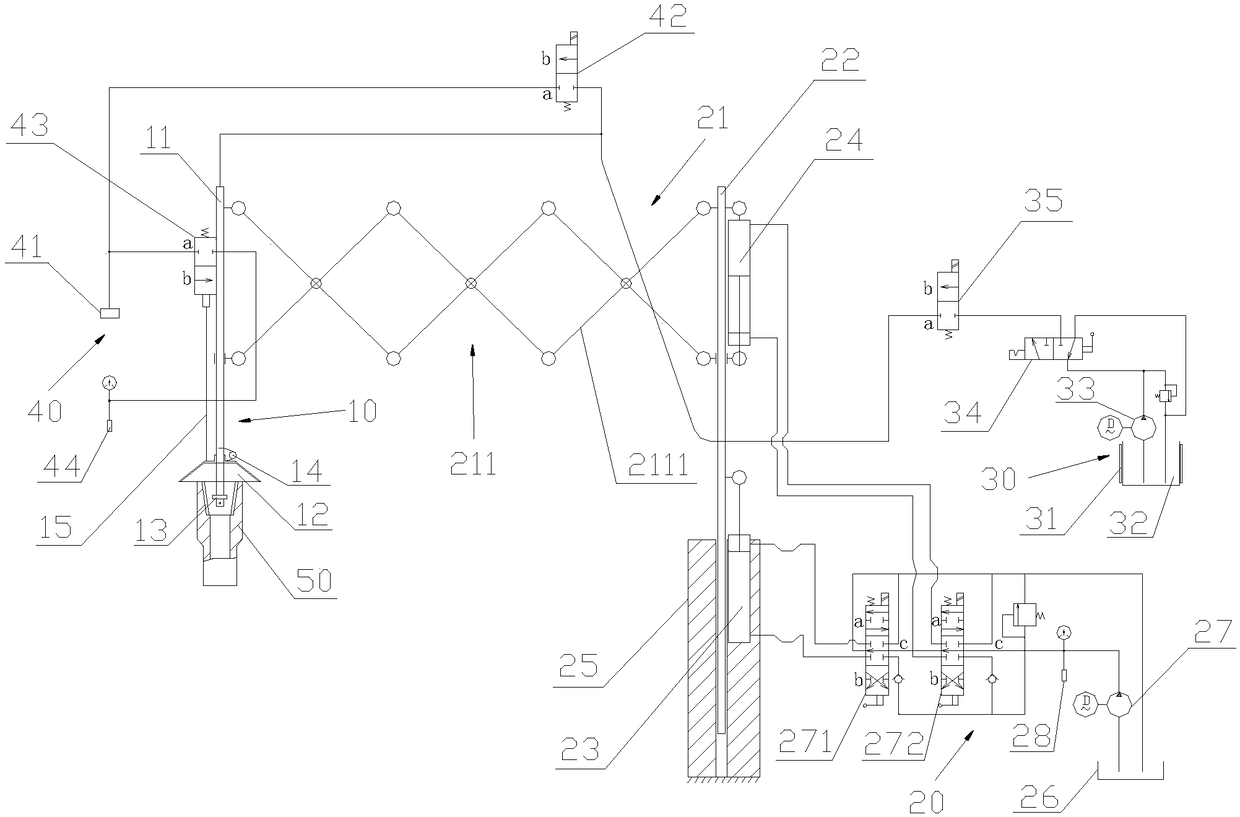

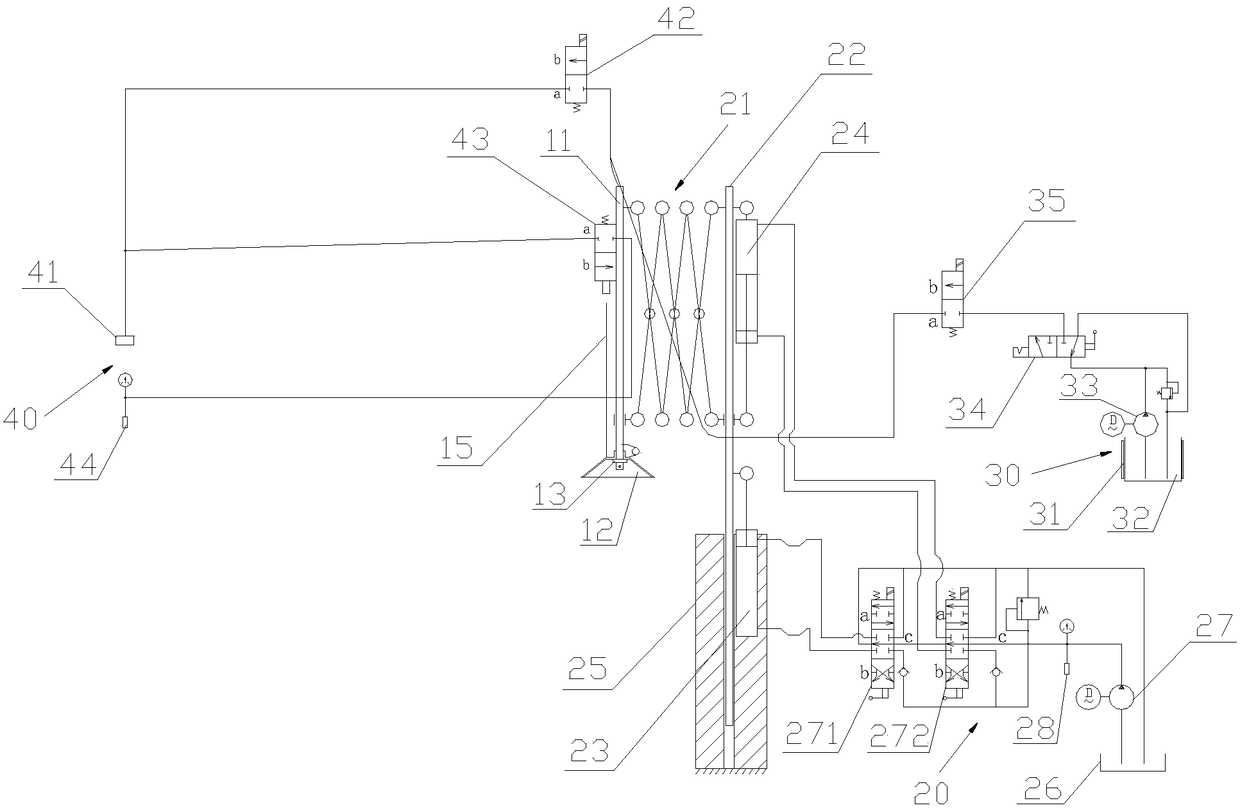

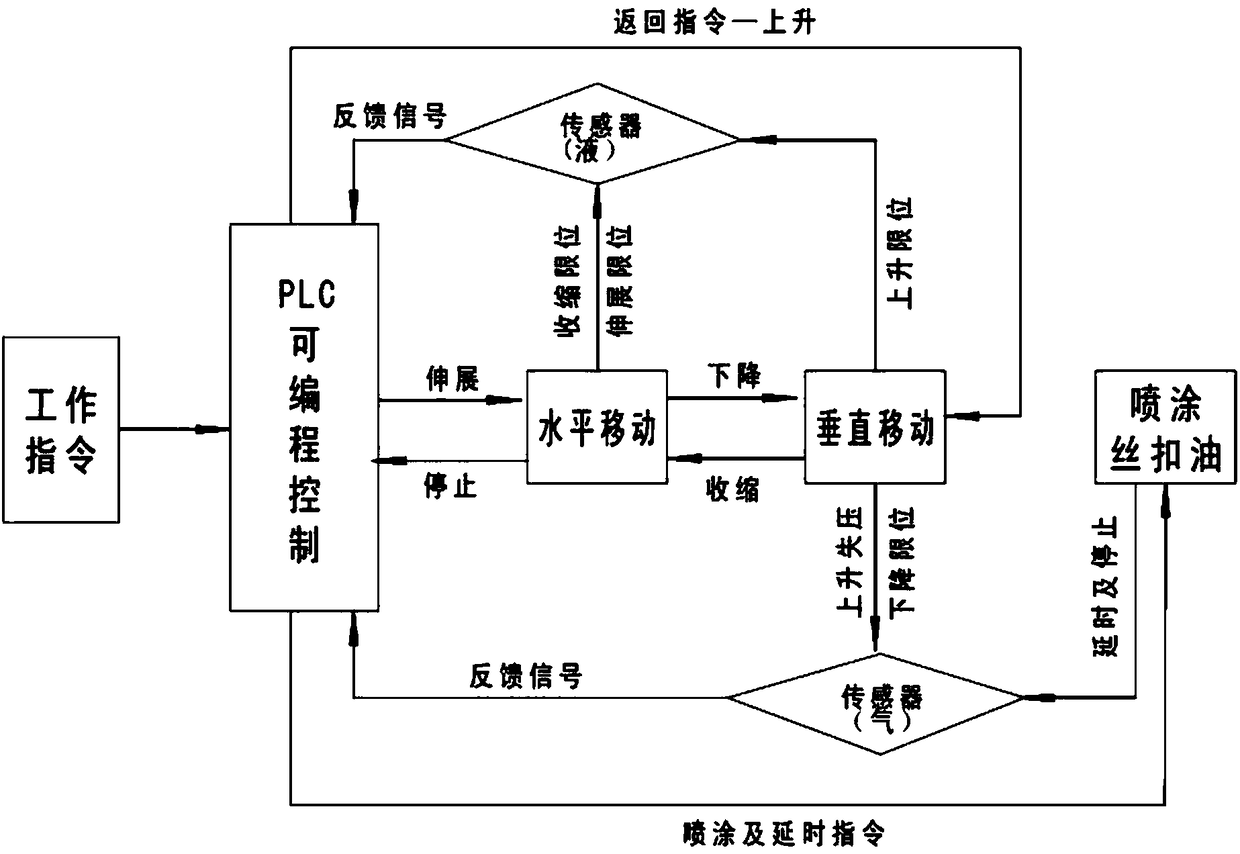

[0014] Such as figure 1 , 2 As shown, the present invention discloses an automatic thread oil application device, which includes a spraying mechanism 10 , a hydraulic moving assembly 20 , an oil supply mechanism 30 , an air supply mechanism 40 and a drill joint 50 .

[0015] Wherein, the spraying mechanism 10 includes a spray rod 11 and a conical cover 12 , the conical cover 12 is sheathed on the spray rod 11 , located at the lower end of the spray rod 11 , and positioned by a torsion spring 14 . Nozzles 13 are installed at the bottom of the spray bar 11 . The hydraulic moving assembly 20 is connected to the spray rod 11, and the hydraulic moving assembly 20 drives the spray rod 11 to move horizontally to the top of the tool joint 50, and drives the spray bar 11 to move up and down to enter and exit the drill tool joint 50. The conical cover 12 follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com