Nut locking point press-fit machine

A nut locking and pressing machine technology, applied in nuts, threaded fasteners, forging/pressing/hammering machinery, etc., can solve the problem of product quality decline, uneven nut edges, and different depths of locking points, etc. problems, to achieve the effect of improving the quality of pressing, improving work efficiency, and ensuring stable and orderly progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

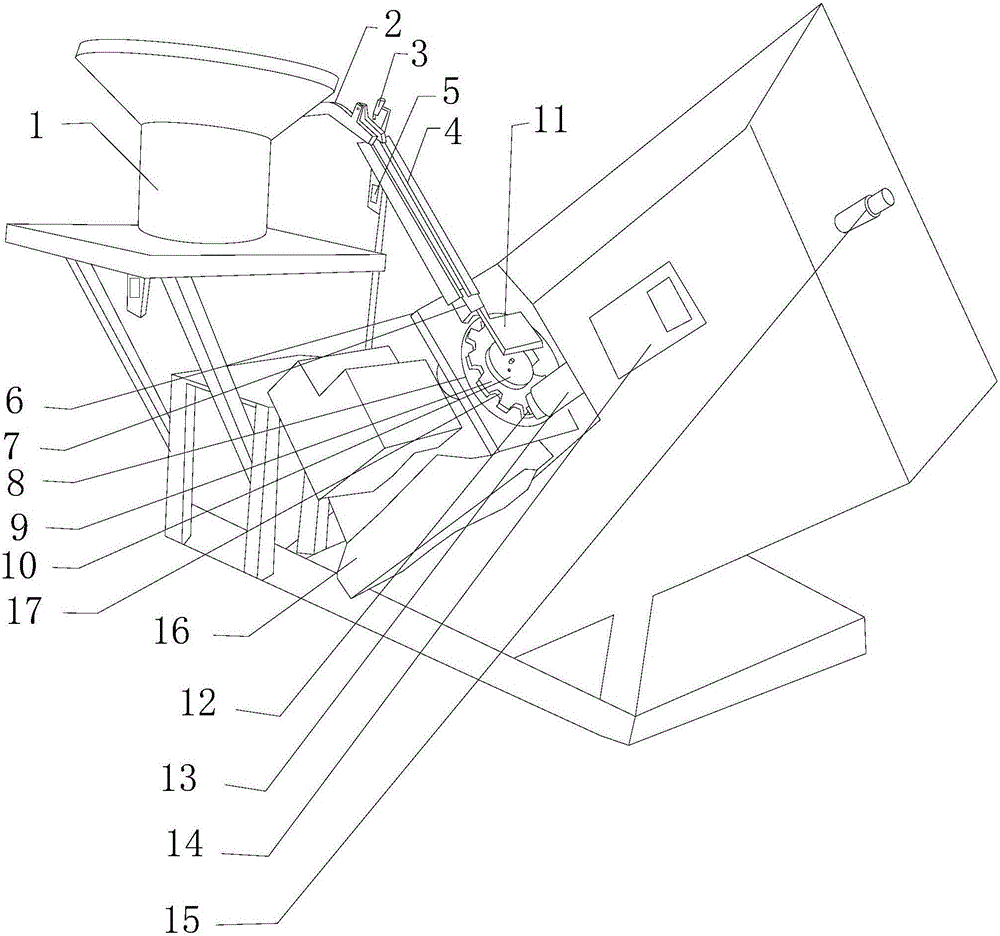

[0014] refer to figure 1 , a nut locking point pressing machine of the present invention, comprising an oscillating feeding device 1, a monolithic bar 2, a monolithic electric eye 3, an arrangement guide groove 4, an oscillating aligner 5, a pressing table 6, and a counting and detecting device 7 , frosting disc 8, pressing turntable 9, limit pressure plate 10, positive positioning device 11, pressing head 12, pressure sensor 13, pressing control center 14, pressing oil cylinder 15, discharge guide groove 16, the The top of the oscillating feeding device 1 is provided with a monolithic bar 2, and the monolithic bar 2 is provided with a monolithic electric eye 3, and the bottom of the monolithic bar 2 is connected with an arrangement guide groove 4, and the arrangement guide groove 4 The bottom is provided with an oscillating aligner 5, and the bottom end of the arrangement guide groove 4 extends to the pressing table 6, and the bottom end of the arrangement guide groove 4 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com