A Seam Tracking Scanner for Welding Robot

A welding robot and scanner technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of reducing equipment flexibility and flexibility, poor water-cooling structure compactness, and high operator ability, and achieve improved accuracy and reliability. Flexibility in production, elimination of errors, improved work efficiency and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

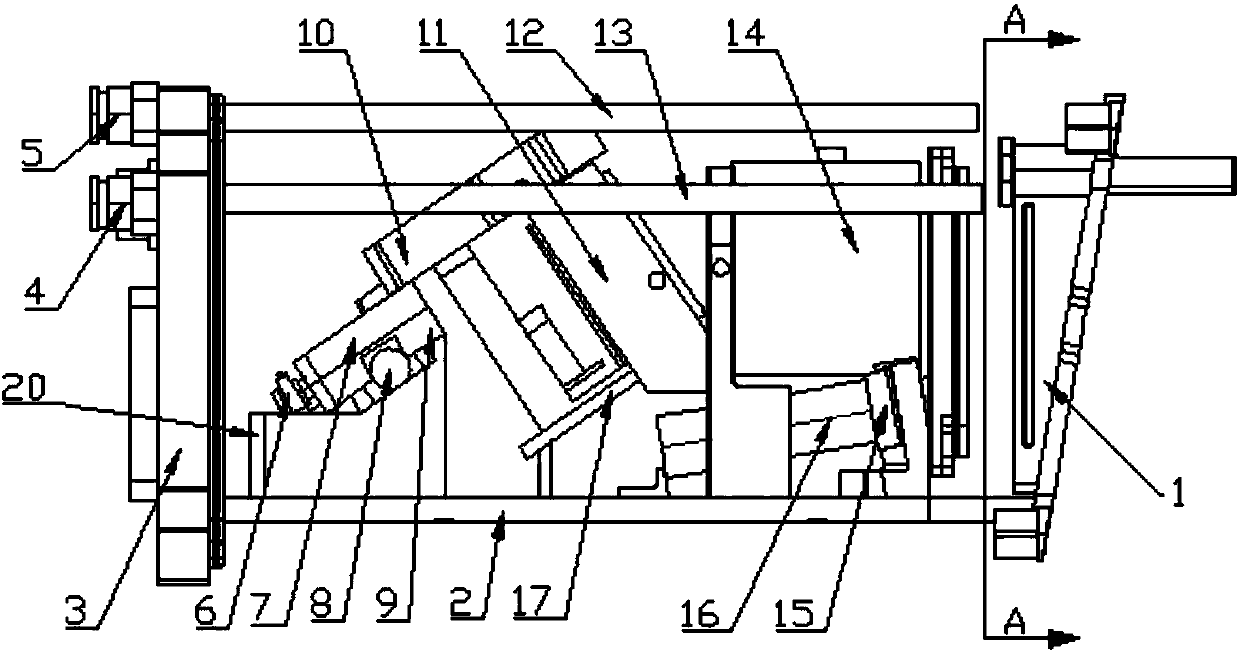

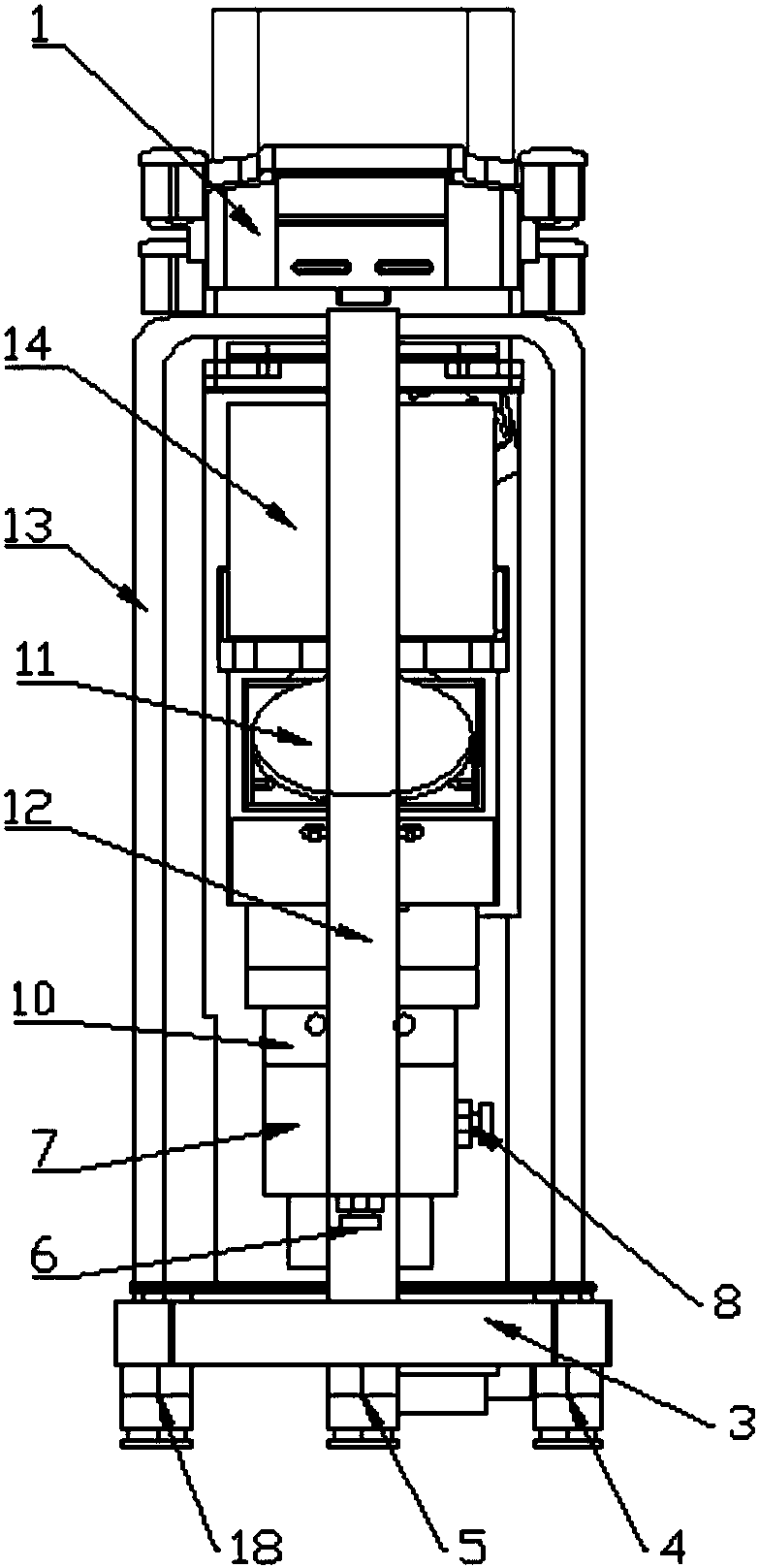

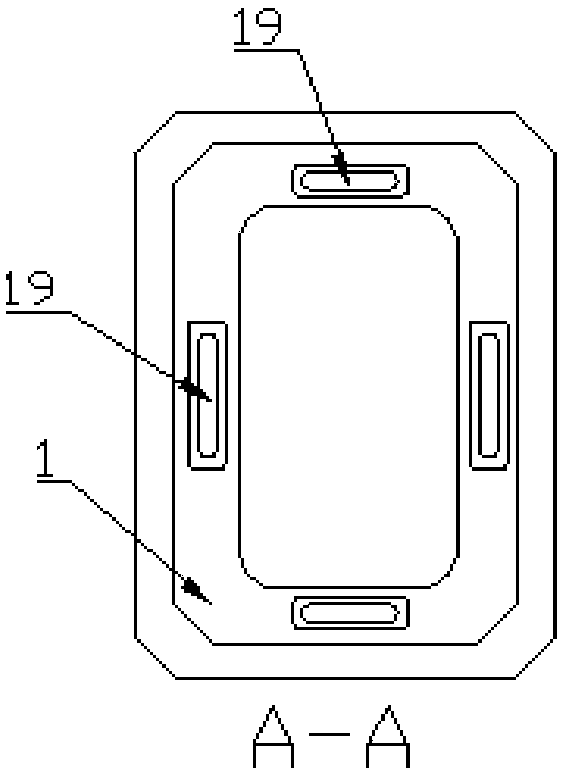

[0026] In addition, a seam tracking scanner for a welding robot mentioned in an embodiment of the present invention includes a front end cover 1, a base 2, a rear end cover 3, a cooling air intake nozzle 4, and a dust removal air intake nozzle 5. Front and rear adjustment buttons 6, front and rear adjustment platforms 7, left and right adjustment buttons 8, left and right adjustment platforms 9, connecting plate 10, first imaging device 11, dust removal air intake pipe 12, cooling pipe 13, lens 14, second imaging device 15, Laser generator 16, support 17, cooling air outlet nozzle 18, dust removal air outlet 19, support plate 20 and casing 21, described casing 21 is provided with cooling pipe 13 and dust removal inlet pipe 12 in hollow, and one end of described base 2 is provided with rear The end cover 3, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com