Thin-wall part machining error measuring device and thin-wall part machining error measurement method based on spatial light modulator

A technology for processing spatial light modulators and thin-walled parts, applied in the optical field, can solve the problems of force deformation of thin-walled curved surfaces, inability to apply online detection, slow measurement speed, etc., to achieve accurate measurement, save measurement space, and save measurement. the effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

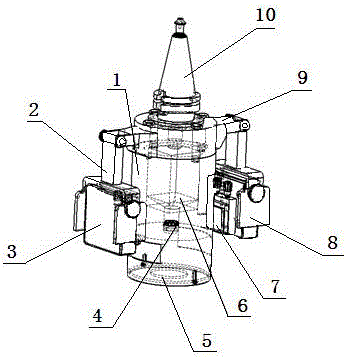

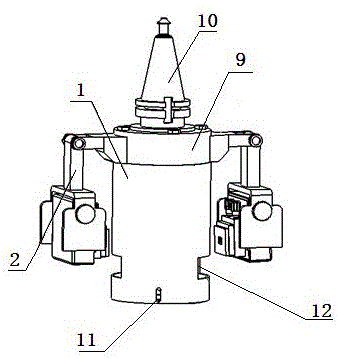

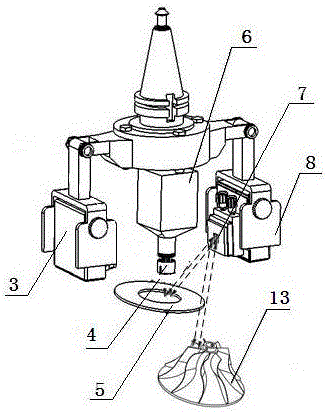

[0036] A processing error measurement device for thin-walled parts based on a spatial light modulator, which consists of: a set of measurement devices 14, the measurement device includes a sleeve 1, and the upper part of the sleeve is connected to the support device 9 by bolts, Both ends of the support device are respectively connected to two modulator card clamping devices 2 through connecting shafts, and the left liquid crystal spatial light modulator 3 and the right liquid crystal spatial light modulator are respectively installed inside the modulator card clamping device. 8. The inner surfaces of the left liquid crystal spatial light modulator and the right liquid crystal spatial light modulator are respectively equipped with polarizers 7, and a digital phase shift interferometer 6 is installed above the sleeve through a square groove.

Embodiment 2

[0038] According to the processing error measurement device for thin-walled parts based on the spatial light modulator described in Embodiment 1, the lens sleeve device 4 is installed under the digital phase-shift interferometer, and the zero position compensation is installed under the inside of the sleeve. The lens device 5 has two protruding blocks on the outside of the zero compensation lens device, and the protruding blocks are installed in the track groove outside the sleeve, and the track device 11 is installed in the track groove , the outer side of the sleeve has two viewing windows 12

Embodiment 3

[0040] According to the processing error measuring device for thin-walled parts based on the spatial light modulator described in Embodiment 1, the upper part of the supporting device is connected to the handle 10 by bolts, and the thin-walled part to be measured is placed in the middle of the group of measuring devices. Workpiece 13.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com