Reflection fabric

A technology of reflective materials and fabrics, applied in the direction of coating, layered products, synthetic resin layered products, etc., can solve the problems of fabrics losing reflective effect, cloth reflective unevenness, etc., and achieve the effect of uniform reflected light and efficient reflective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

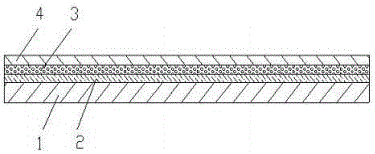

[0015] Example 1: Firstly, take a roll of polyester cloth as the cloth base 1, apply the mixture of acrylic resin glue and yellow dye evenly on one surface by the top coater, and use the wind to dry and solidify.

[0016] Secondly, on the base layer 2 after drying, coat high-refractive-index glass beads and their solvents, adopt glass beads of the same size to ensure the thickness uniformity of the reflective coating, and use a micro-vibration plate to make the glass beads during coating. The beads are evenly distributed.

[0017] Then apply glue on the transparent BOPP film, then cover the film on the glass bead coating, and finally put it on the machine for thermocompression molding.

[0018] The application of the reflective fabric, colored waterproof base layer and high-transparency film of the present invention provides a good working environment for reflective materials, with good reflective performance, uniform light reflection, bright colors, durable and not easy to fa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com