Multistage collision energy absorption rail guard

A technology for collision energy absorption and barrier remover, applied in the field of rail vehicles, can solve the problems of difficult disassembly and replacement, no energy absorption function, waste of undamaged parts, etc., and achieve the effects of easy replacement, improved interchangeability and utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

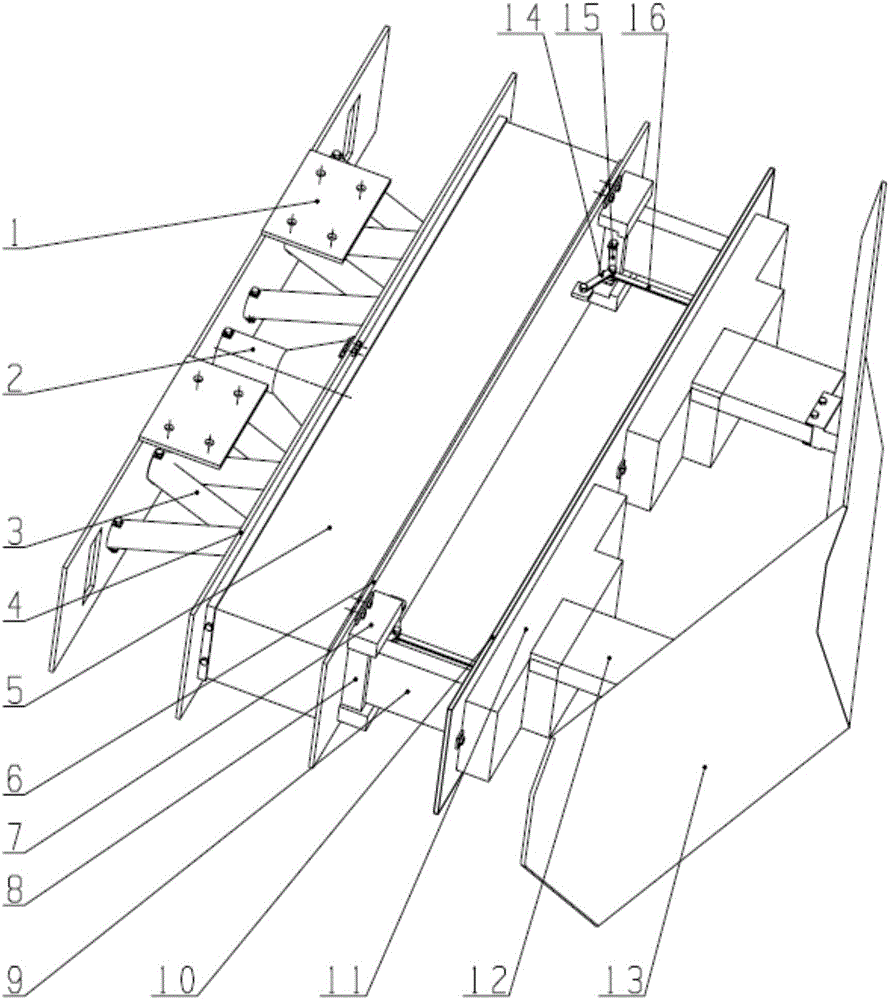

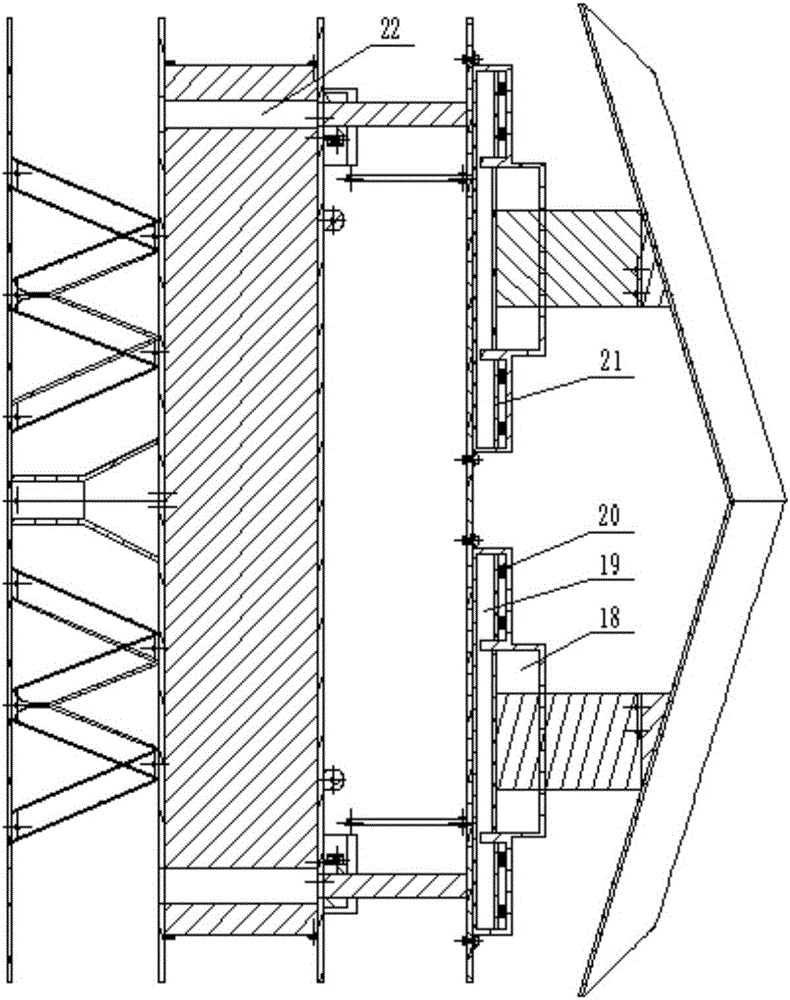

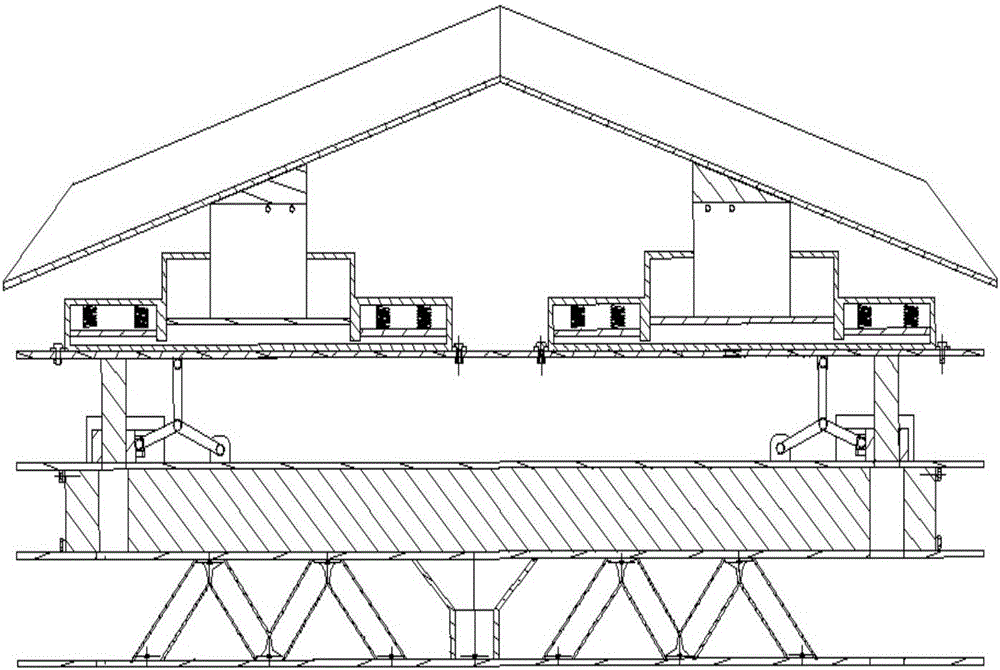

[0032] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the multi-stage collision energy-absorbing obstacle remover of the present invention includes a first-stage hydraulic buffer energy-absorbing module, a second-stage frictional energy-absorbing module, a third-stage aluminum honeycomb energy-absorbing module, and a fourth-stage energy-absorbing pipe energy-absorbing module;

[0033] The energy-absorbing module is preceded by the first-stage hydraulic buffer energy-absorbing module, and the first-stage to fourth-stage energy-absorbing modules are installed sequentially from front to back;

[0034] The first-level hydraulic buffer energy-absorbing module and the second-level frictional energy-absorbing module are connected through the baffle Ⅲ10, the second-level frictional energy-absorbing module and the third-level aluminum honeycomb energy-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com