Supporting rack of steel coil transporting device and steel coil transporting device

The technology of a transport device and a support frame is applied in the field of a support frame and a steel coil transport device, which can solve the problem that it is difficult to ensure the support strength of the steel coil, and achieve the effects of weight reduction, light weight and structural strength enhancement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

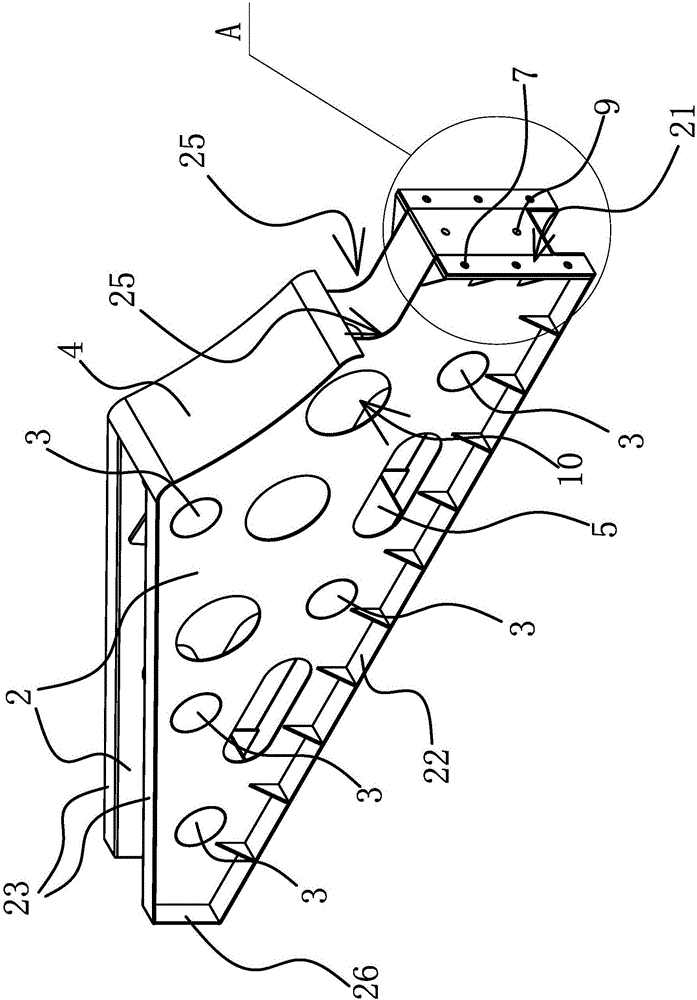

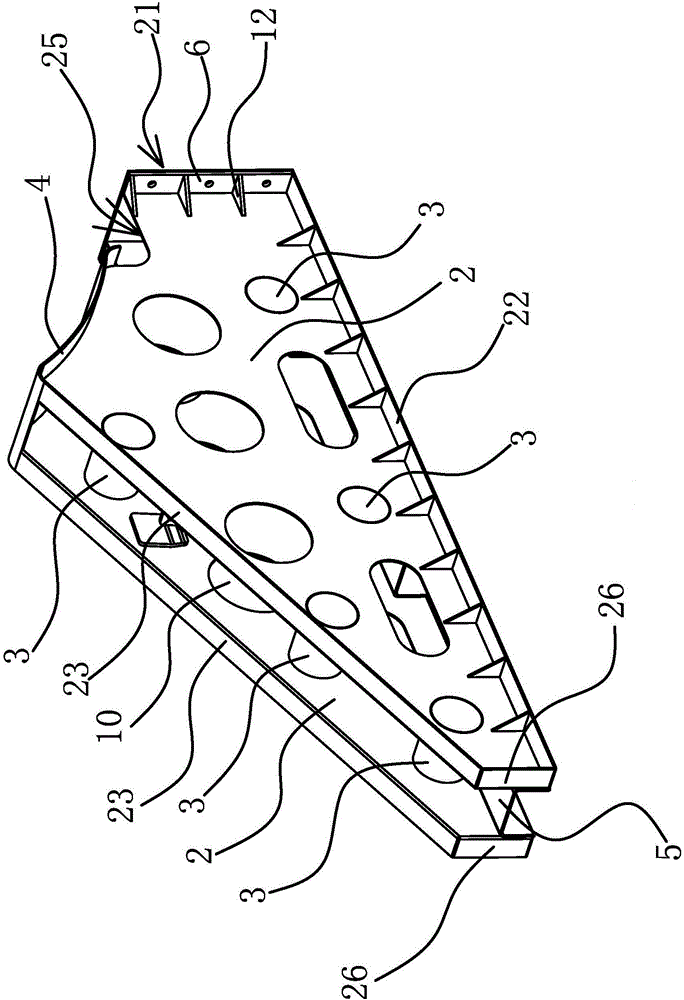

[0043] like Figure 1 to Figure 5 As shown, the support frame 13 of the steel coil transportation device includes two side plates 2, the two side plates 2 are opposite and arranged at intervals, and the two side plates 2 are fixed by a fixing part 3, and the fixing part 3 is a hollow cylindrical structure. The fixing part 3 is made of metal material, and the two ends of the fixing part 3 are vertically connected to the two side plates 2 respectively. There are 6 fixing parts 3, and the 6 fixing parts 3 are arranged adjacent to the bottom edge of the side plate 2 and the upper edge of the side plate 2 respectively, and the 3 fixing parts 3 adjacent to the bottom edge of the side plate 2 are arranged along the side The length direction of the bottom edge of the board 2 is arranged at intervals, and the three fixing pieces 3 adjacent to the upper edge of the side plate 2 are arranged at intervals along the length direction of the inclined section.

[0044] like figure 2 As sho...

Embodiment 2

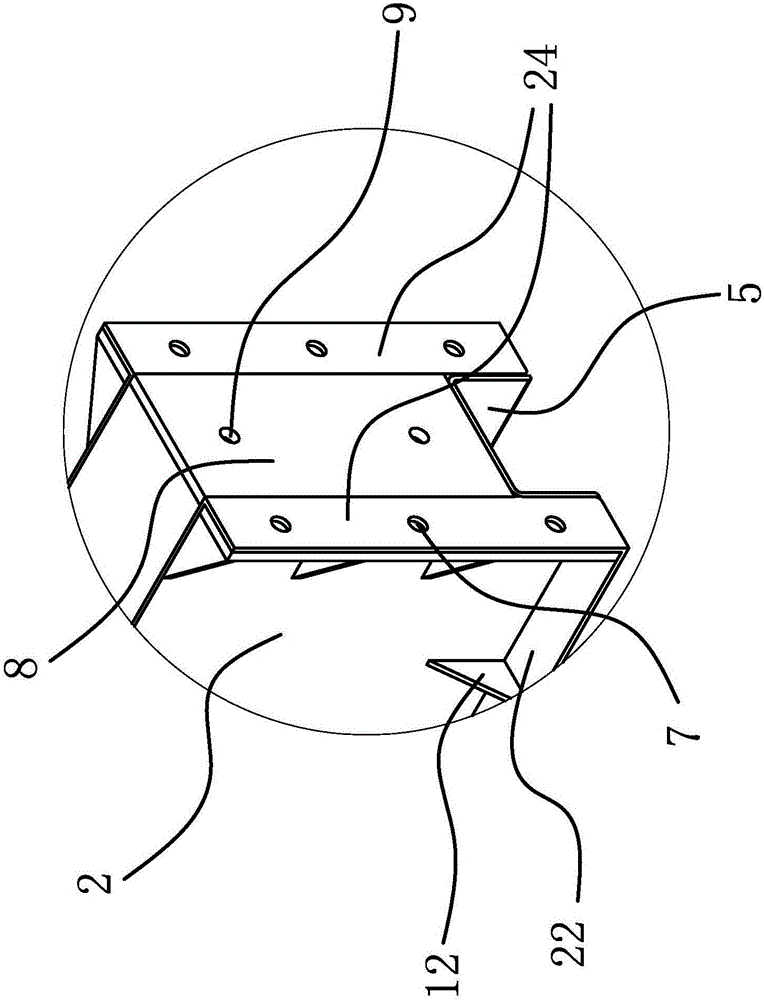

[0053] Such as 1, Image 6 and Figure 7 As shown, the steel coil transportation device includes four support frames 13 . Each supporting frame 13 includes two side plates 2 , the two side plates 2 are opposite and arranged at intervals, and the two side plates 2 are fixed by a fixing member 3 . The bottom between the two side plates 2 is provided with a connecting piece 5 which can be connected with the guide rail, and the connecting piece 5 is fixedly connected with the two side plates 2 respectively. The bottom edge of each side plate 2 has a support flange 22 perpendicular to the surface of the side plate 2, and the side edge of the side plate 2 has a connecting portion 21 for connecting the two support frames 13, such as Figure 8As shown, the connecting portion 21 includes a connecting flange 24 integrally formed on the side of the side plate 2. The connecting flange 24 is in the shape of a flat plate, and the lower end of the connecting flange 24 is connected with the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap