Diaphragm automatic roll changing device

A diaphragm, automatic technology, applied in the direction of winding strips, transportation and packaging, thin material handling, etc., can solve the problems of increasing idle time of equipment, incapable of continuous use of material belts, increasing people and diaphragms, etc., to save time for roll change , Save the time of manual waiting and change the material roll, and improve the work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

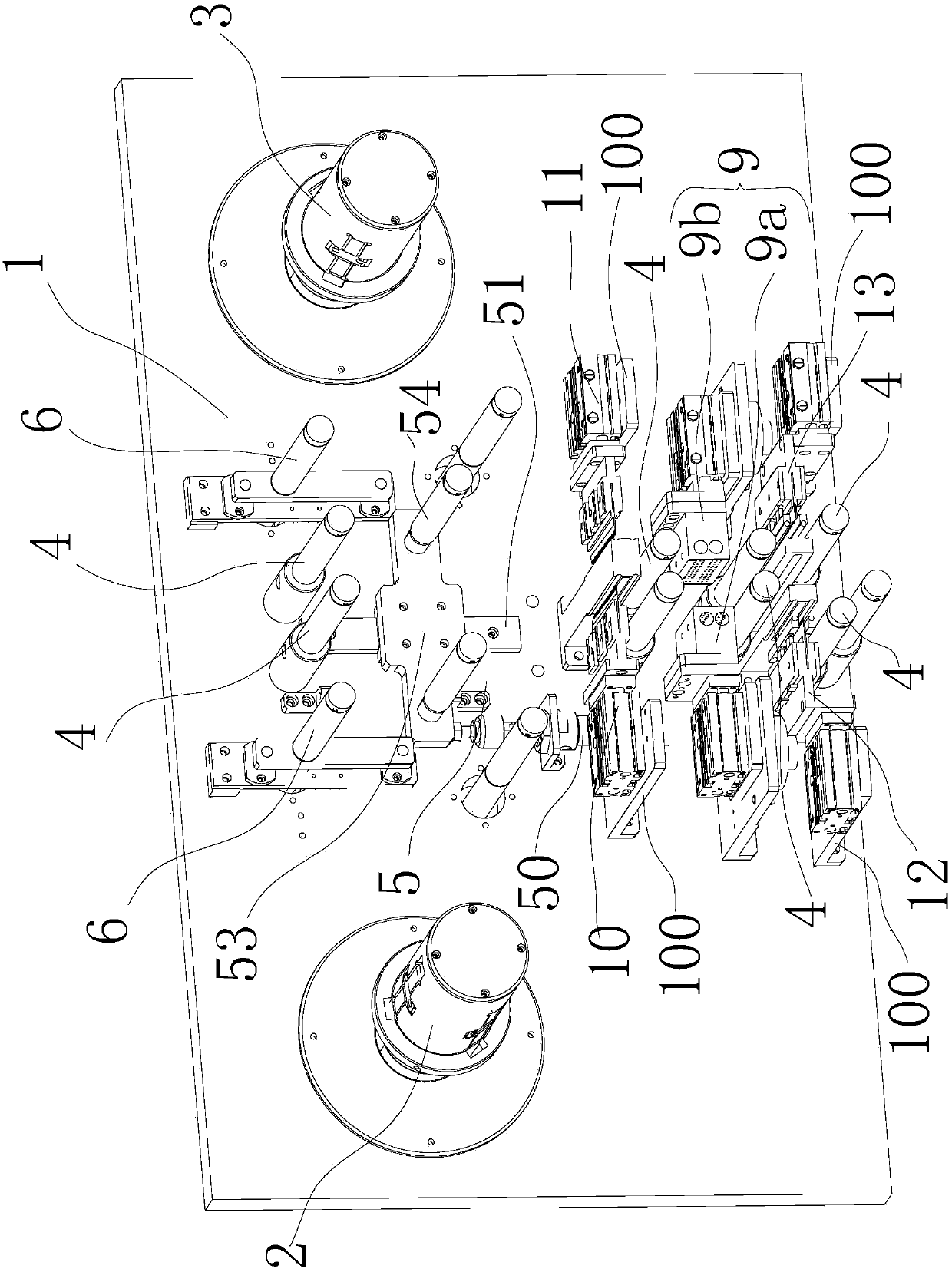

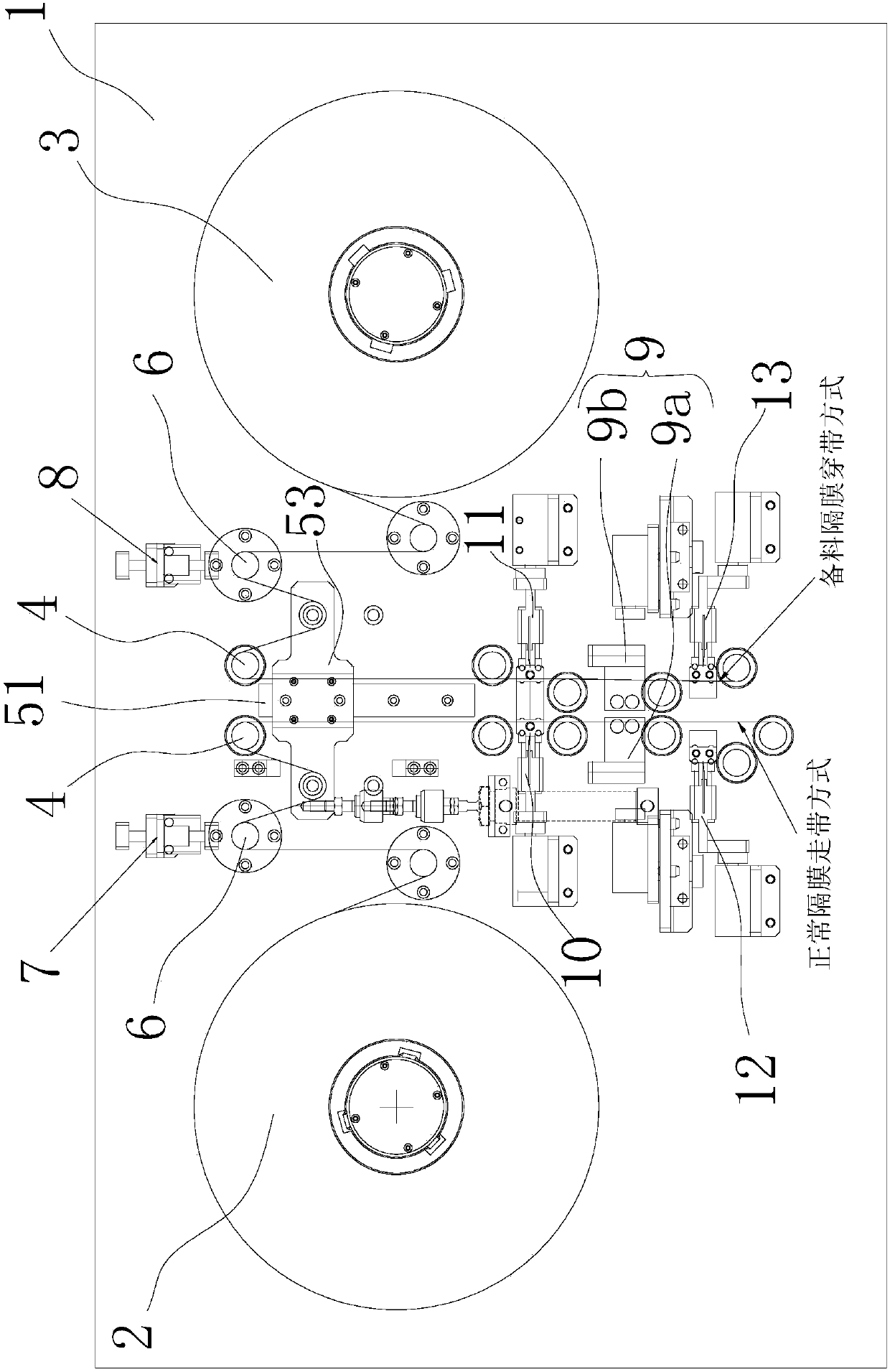

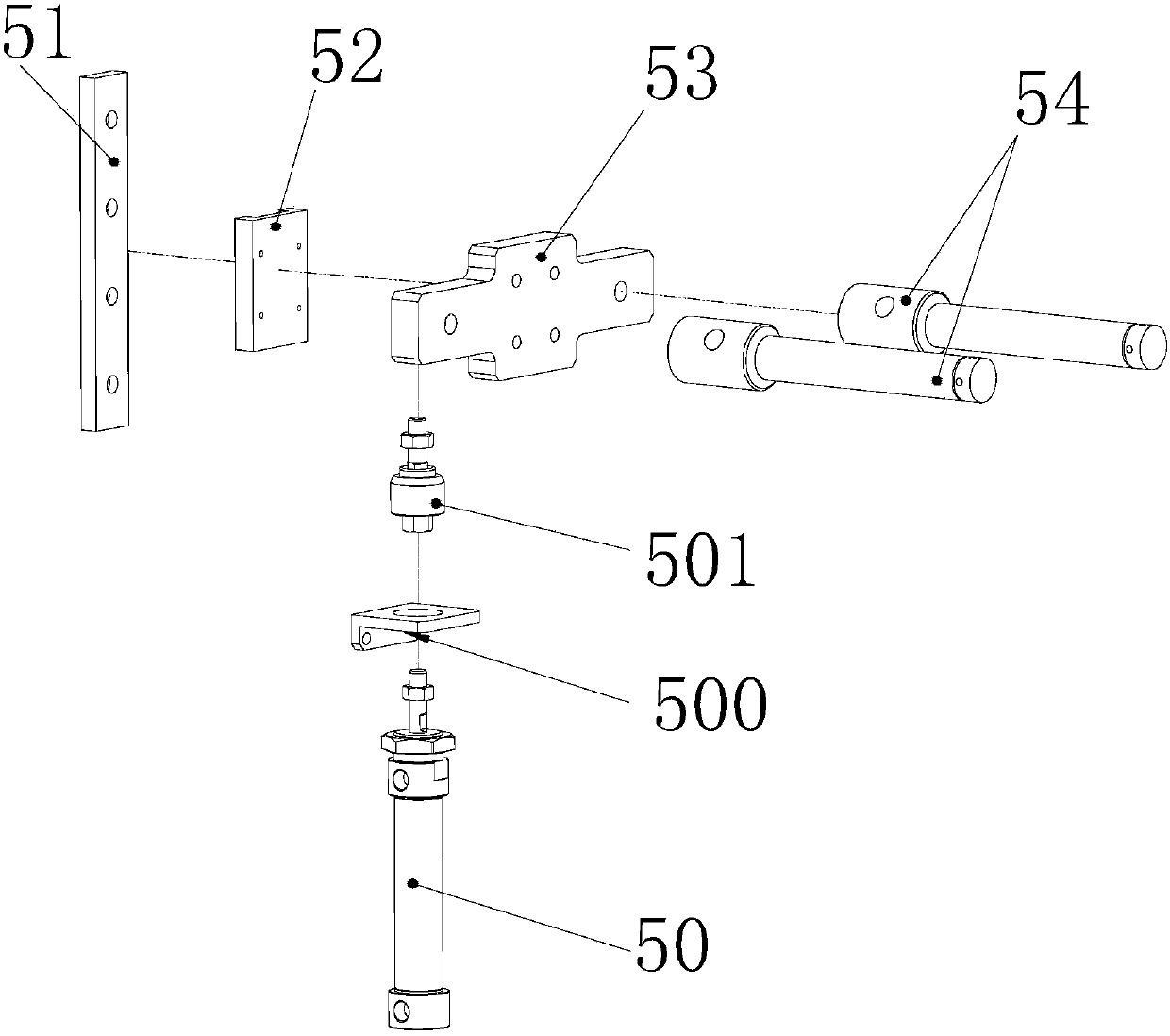

[0031] Diaphragm automatic roll changing device, such as Figure 1 to Figure 8 As shown in the figure, it is used for the winding process of the battery automatic winding machine, including the vertical substrate 1, and the conveying direction of the diaphragm is perpendicular to the substrate 1; the left and right sides of the substrate 1 are respectively equipped with main The material roll mechanism 2 and the spare material roll mechanism 3, the diaphragm material rolls installed on the main material roll mechanism 2 and the spare material roll mechanism 3 are mutually spare for the winding process to provide the released diaphragm in turn; the middle part of the substrate 1 is respectively installed There are two rows of multiple rollers 4 that are convenient for the diaphragms on the main roll mechanism 2 and the spare roll mechanism 3 to carry out material preparation and threading respectively and then tow and freely suspend.

[0032] continue as Figure 1 to Figure 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com