Rewinding machine with surface drive function

A rewinding machine and rewinding roller technology, applied in the field of rewinding machines, can solve the problems of the bulkiness of the substrate being too tight on the outside and loose on the inside, and the tension cannot be recovered due to high tension. Guaranteed effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

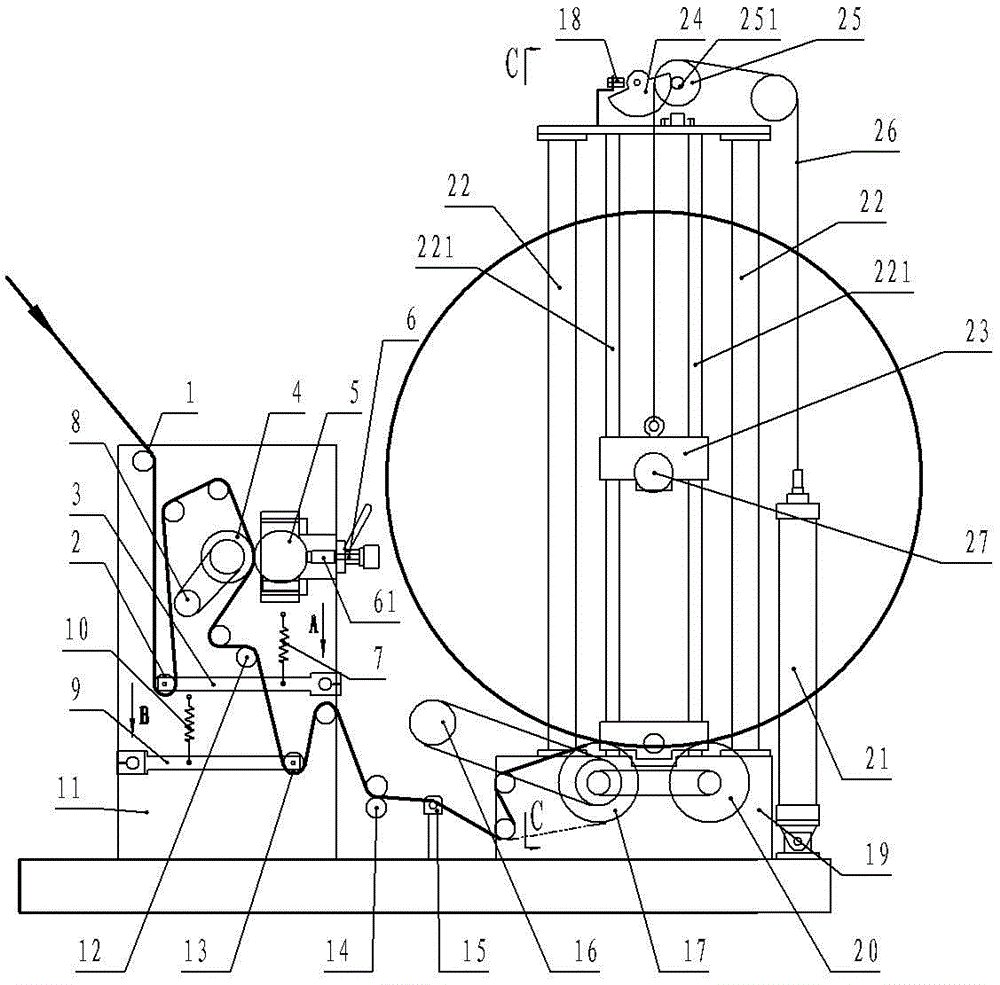

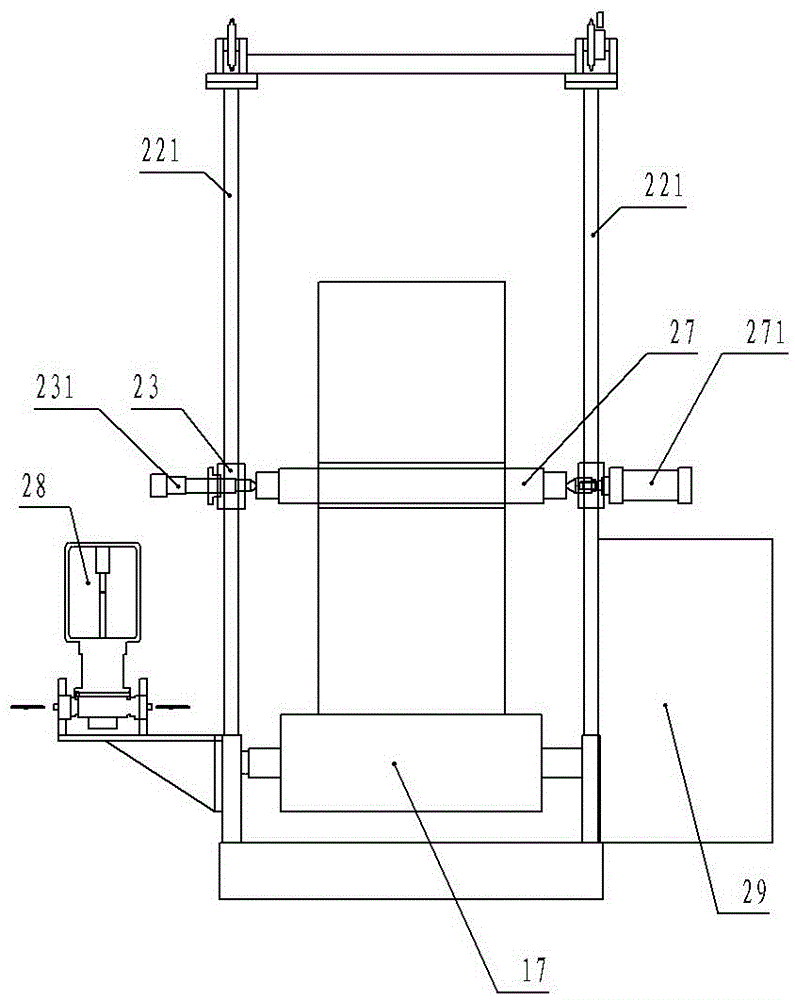

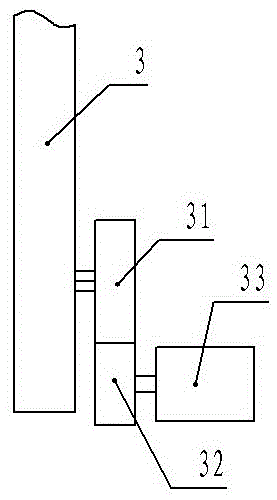

[0017] figure 1 , figure 2 The surface-driven rewinding machine shown includes a traction unit and a rewinding unit. The traction unit includes a paper traction tension detection device and a traction roller. The paper traction tension detection device includes a fixed roller 1 on the paper input channel and The first swing lever 3 that is connected with the first extension spring 7, one end of the first swing lever 3 is connected with the first floating roller 2, as image 3 As shown, the other end of the first swing lever 3 is fixedly connected to the gear 31, the first swing lever 3 can swing around the axis of the gear 31, and the gear 31 is meshed with the gear 32 on which the first sensor 33 is installed; the first sensor 33 is used To detect the rotation position of the first swing lever 3; two traction rollers that are pressed against each ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com