A method for promoting aerobic sludge granulation by mycelium balls

A technology of aerobic sludge and mycelium balls, which is applied in the field of environmental bioengineering, can solve the problems of shortening the sludge granulation culture period, slow sludge sedimentation speed, and low sludge concentration, and achieves shortened culture period and easy operation , Enhance the effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

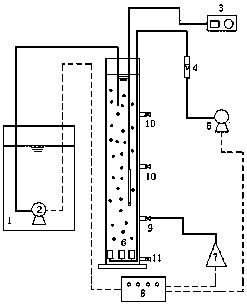

Method used

Image

Examples

Embodiment 1

[0031] 1. Preparation of chlorophenol simulated wastewater

[0032] Use tap water to prepare simulated wastewater containing 2-chlorophenol, and its components include: 0.5 g / L glucose, 0.1 g / L (NH4)2SO4, 0.05 g / L MgSO4 7H2O, 0.062 g / L KH2PO4, 0.062 g / L K2HPO4, 0.012 g / L CaSO4, 50 mg / L 2-chlorophenol, pH natural. At this point, the influent COD concentration is about 550 mg / L.

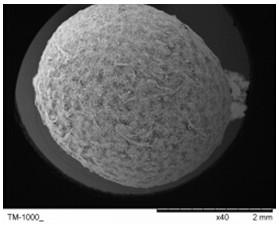

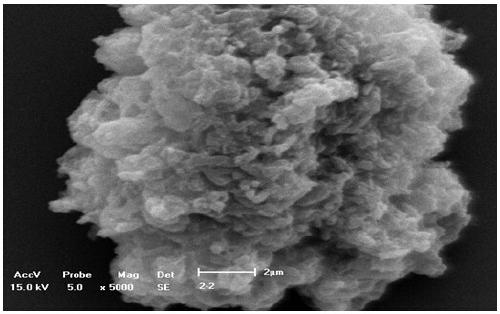

[0033] 2. Preparation of mycelium balls

[0034] On the aseptic operating bench, use a sterile pipette to pipette 10 ml of fungal spore suspension (about 105 spores per ml of deionized water) into a conical flask filled with 90 ml of sterile chlorophenol simulated wastewater. Seal the Erlenmeyer flask with sterile gauze and place it in an air bath shaker for shaking culture at a speed of 160 rpm and a culture temperature of 30°C. After culturing to form mycelium balls with uniform size and a diameter of about 2 mm, take them out and filter them with sterile gauze, wash them with sterile normal salin...

Embodiment 2

[0042] 1. Preparation of simulated chlorophenol wastewater

[0043] Use tap water to prepare simulated wastewater containing 2-chlorophenol, and its components include: 1.5 g / L glucose, 0.5 g / L (NH4)2SO4, 0.05 g / L MgSO4 7H2O, 0.01 g / L KH2PO4, 0.01 g / L K2HPO4, 0.02 g / L CaSO4, 100 mg / L 2-chlorophenol, pH natural. At this time, the influent COD concentration is about 1700 mg / L.

[0044] 2. Preparation of mixed mycelium balls

[0045] On a sterile operating bench, use a sterile pipette to inoculate 10 ml of fungal spore suspension (about 107 spores per ml of deionized water) into 90 ml of sterilized and cooled simulated chlorophenol wastewater. After the Erlenmeyer flask was sealed with sterile gauze, it was placed in an air bath shaker for shaking culture at a speed of 180 rpm and a culture temperature of 28°C. After culturing to form mycelium balls with uniform size and a diameter of about 1 mm, take them out and filter them with sterile gauze, wash them with sterile normal s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com