A kind of machine-made sand dust collection ash dry-mixed mortar and its preparation method

A dry-mixed mortar and dust collection technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as limitations, achieve low cost, increase mortar density, and improve consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

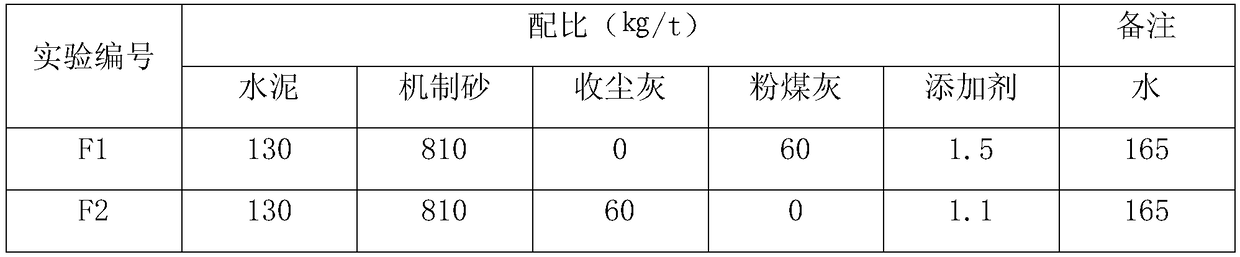

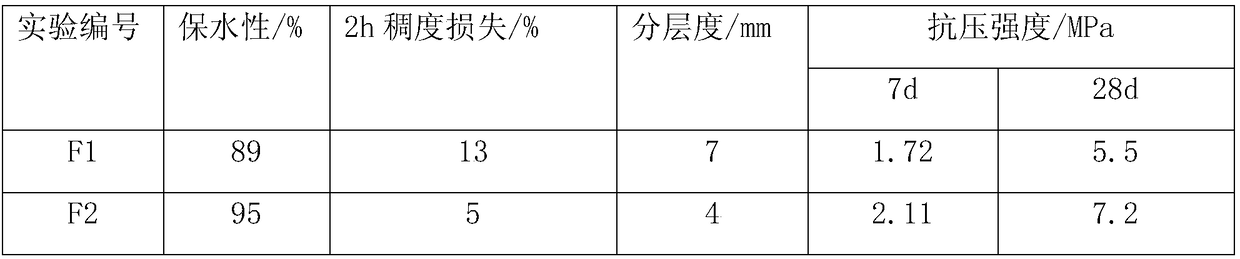

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: A machine-made sand and dust collection dry-mix mortar, which is composed of the following raw materials in parts by weight: cement: 1; sand: 5; dust collection ash: 1; admixture: 0.5; wherein, the dust collection ash The particle size of the particles is ≤0.075mm, the water content is 0.3%, the bulk density is 1800g / L, and the shape is almost round. Wherein, the SiO 2 The content is 75%, Al 2 o 3 The content is 20%, Fe 2 o 3 The content of MgO is 3%, the content of MgO is 1%, K 2 O content 2 The content of O is less than 1%, and the content of CaO is less than 3%. The additive is a water-retaining thickener.

Embodiment 2

[0032] Embodiment 2: A dry-mixed mortar for machine-made sand and dust collection, which is composed of the following raw materials in parts by weight: cement: 5; sand: 15; dust collection ash: 5; admixture: 1; wherein, the dust collection ash The particle size of the particles is ≤0.075mm, the water content is 0.5%, the bulk density is 1800g / L, and the shape is almost round. Wherein, the SiO 2 The content is 85%, Al 2 o 3 The content is 10%, Fe 2 o 3 The content of MgO is 3%, the content of MgO is 1%, K 2 O content 2 The content of O is less than 1%, and the content of CaO is less than 3%. The admixture is a mixture of redispersible polymer rubber powder and fiber-reinforced anti-cracking material in any proportion.

Embodiment 3

[0033] Embodiment 3: A dry-mixed mortar for machine-made sand dust collection, which is composed of the following raw materials in parts by weight: cement: 2; sand: 6; dust collection ash: 2; admixture: 0.6; wherein, the dust collection ash The particle size of the particles is ≤0.075mm, the water content is 0.34%, the bulk density is 1800g / L, and the shape is almost round. Wherein, the SiO 2 The content is 78%, Al 2 o 3 The content is 12%, Fe 2 o 3 The content of MgO is 5%, the content of MgO is 2%, K 2 O content 2The content of O is less than 1%, and the content of CaO is less than 3%. The admixture is a mixture of plastic water reducer, air entraining agent and early strengthening agent in any proportion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com