A kind of aluminum or aluminum alloy smelting covering agent and preparation method thereof

A covering agent and aluminum alloy technology, which is applied in the field of metal smelting materials and production, can solve the problems of consuming crops and pasture, strong seasonality, and unfavorable development of agricultural and animal husbandry production, so as to save straw and pasture, improve smelting quality, and realize The effect of a virtuous circle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] specific implementation plan

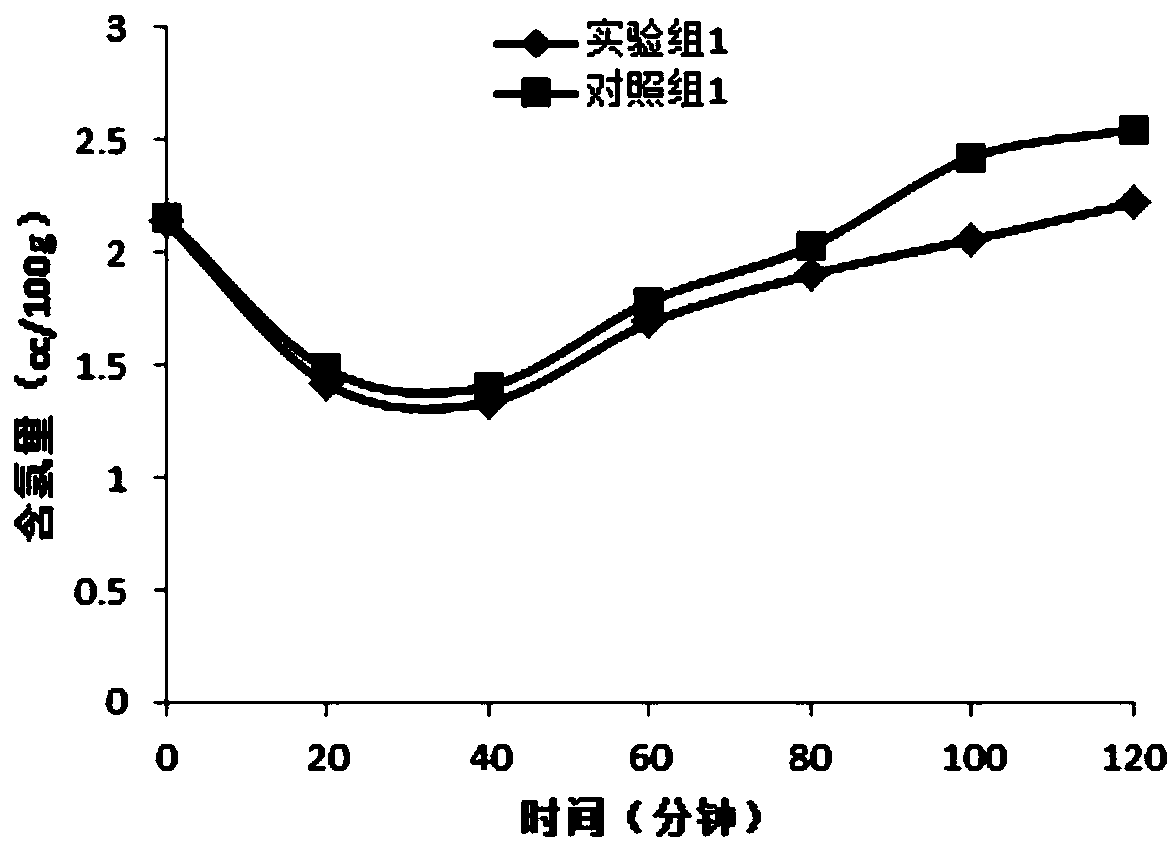

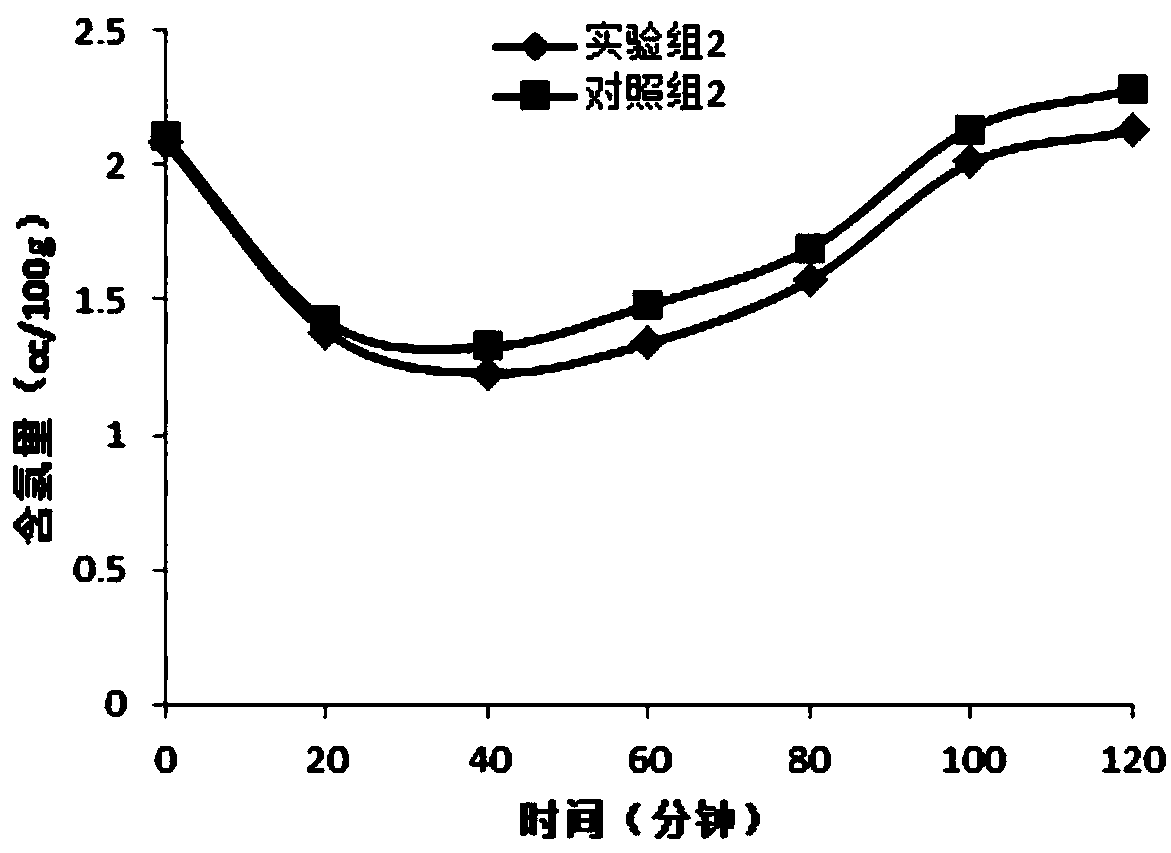

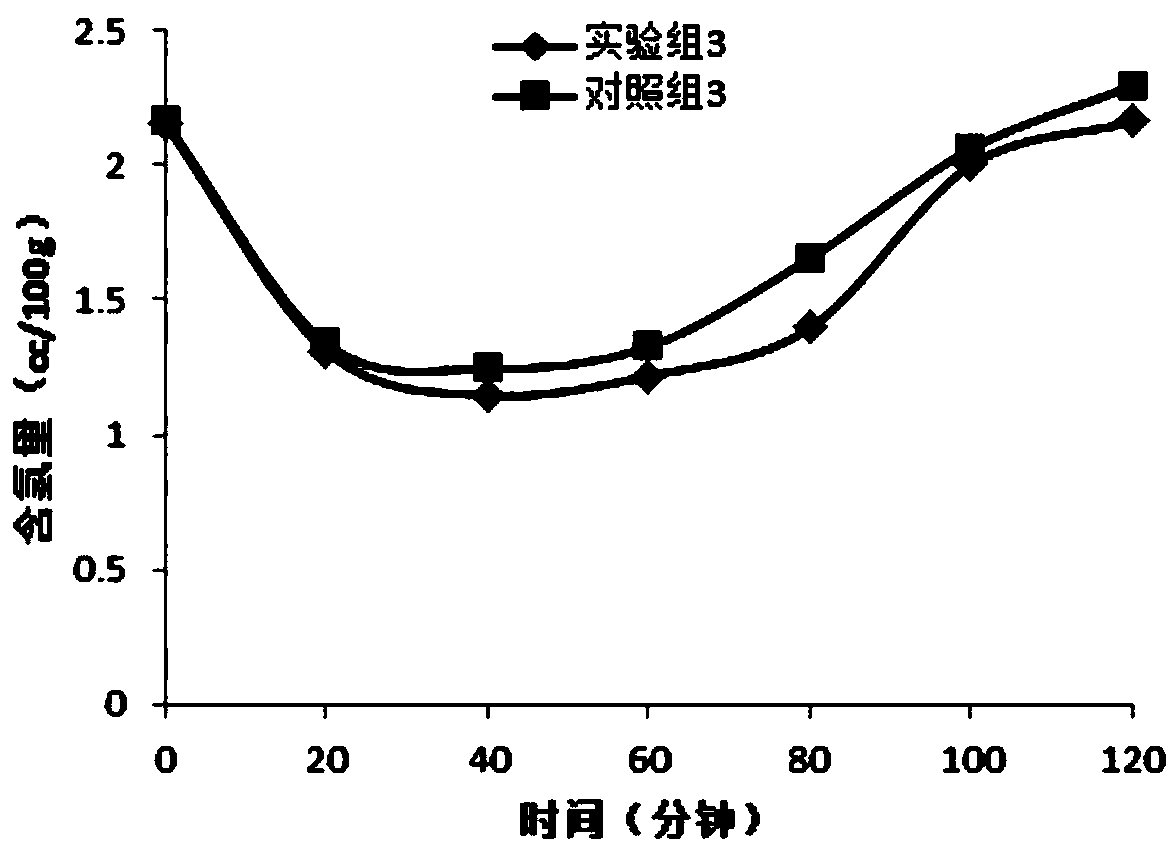

[0077] The general idea of the present invention is to use cow dung to prepare the covering agent used in the smelting process of aluminum or aluminum alloy. Four embodiments are described below in conjunction with the accompanying drawings.

[0078] The first kind of embodiment: take cow dung as raw material, through drying, pulverizing, make powdery covering agent. There are many processing methods available, and only one method is recommended below, including the following steps:

[0079] (1) collection, collection of cow dung;

[0080] (2) drying, the collected cow dung is air-dried and air-dried to reduce its moisture content to 8-14%;

[0081] (3) pulverize, the dried cow dung is pulverized;

[0082] (4) Drying, drying the crushed dry cow dung to constant weight, the drying temperature is preferably below 105°C;

[0083] (5) Sieve, use a 4-10 mesh sieve to screen the pulverized cow dung, return the cow dung with larger particl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com