A zipper electroplating device

An electroplating device and zipper technology, which are applied to electrolytic components, electrolytic processes, clothing, etc., can solve problems such as affecting the effect of electroplating, zipper dropping grooves, etc., and achieve the effects of convenient socket connection, convenient installation and disassembly, and improved electroplating efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

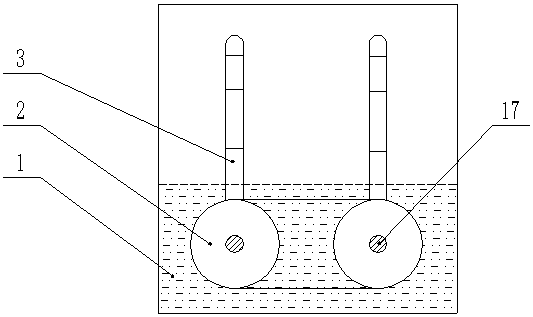

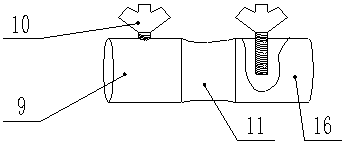

[0020] Example 1, such as figure 1 A kind of zipper electroplating device shown, at first offer two strip holes 3 identical and on the same horizontal plane on the rear wall of the electroplating tank 1, then install a sealing telescopic block 13 in each strip hole 3, and seal the telescopic block 13 structured as Figure 4 As shown, the telescopic sleeves at both ends are slightly larger than the telescopic sleeves in the middle, and the upper and lower ends of the sealed telescopic block 13 are correspondingly fixed on the top and bottom of the strip hole 3, and at the same time, a rolling shaft hole 14 is opened in the middle, and the rolling shaft A rolling shaft 17 is sleeved in the hole 14, and one end of the rolling shaft 17 in the electroplating tank 1 is fixedly provided with a scroll wheel 2, and each scroll wheel 2 outer edge circumference is provided with three roads such as Figure 5 The arc-shaped groove shown.

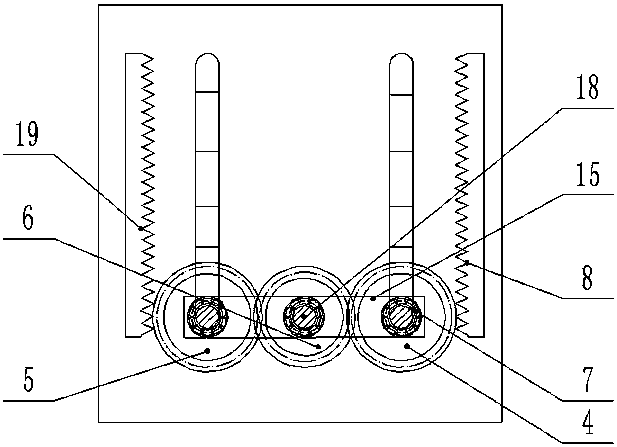

[0021] Such as figure 2 As shown, the rolling ...

Embodiment 2

[0023] Embodiment 2, the difference with embodiment 1 is: as Image 6 As shown, the web-type roller 20 is used to replace the scroll wheel in Embodiment 1. The web-type roller 20 includes a bush, and the bush is connected to the scroll shaft through a keyway. Four webs are uniformly welded outside the shaft sleeve, and the top of each web is provided with an inwardly concave curved surface. In addition, the web is divided into two parts from the middle, the part near the top is the web shell 21 , and the other part is the web shaft 22 . Such as Figure 7 As shown, the web shell 21 is hollow, the internal cross section is slightly larger than the cross section of the web shaft 22 , and has no bottom surface, and the web shell 21 is sleeved on the top of the web shaft 22 . The top of the web shaft 22 is connected to the inner top of the web shell 21 by a spring 24, and the outer peripheral wall of the bottom of the web shell has a plurality of evenly distributed liquid inlet h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com