A kind of heat recycling equipment for asphalt mixture plant

A kind of asphalt mixture and heat regeneration technology, which is applied in roads, road repairs, roads, etc., can solve problems such as downtime maintenance, affecting equipment production efficiency, and inability to continue production, so as to reduce failure rate, facilitate switching, and reduce occupied space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

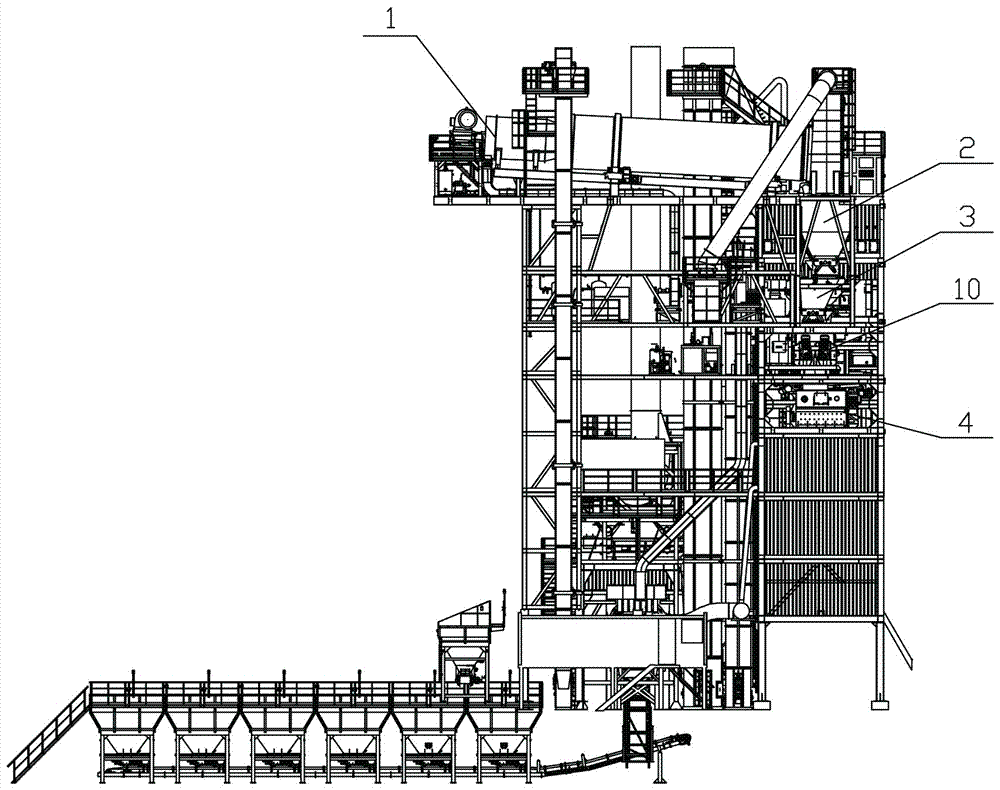

[0028] A kind of asphalt mixture plant mixing heat regeneration equipment, refer to figure 1 , including a recycled material heating system 1, a recycled material storage bin 2 located behind the recycled material heating system 1, a recycled material weighing hopper 3 located below the recycled material storage bin 2, and a main mixing cylinder 4. The recycled weighing hopper 3 A regenerated material pre-mixing device 10 is also provided below the main mixing tank 4, and the regenerated material pre-mixing device 10 is arranged directly above the main mixing tank 4.

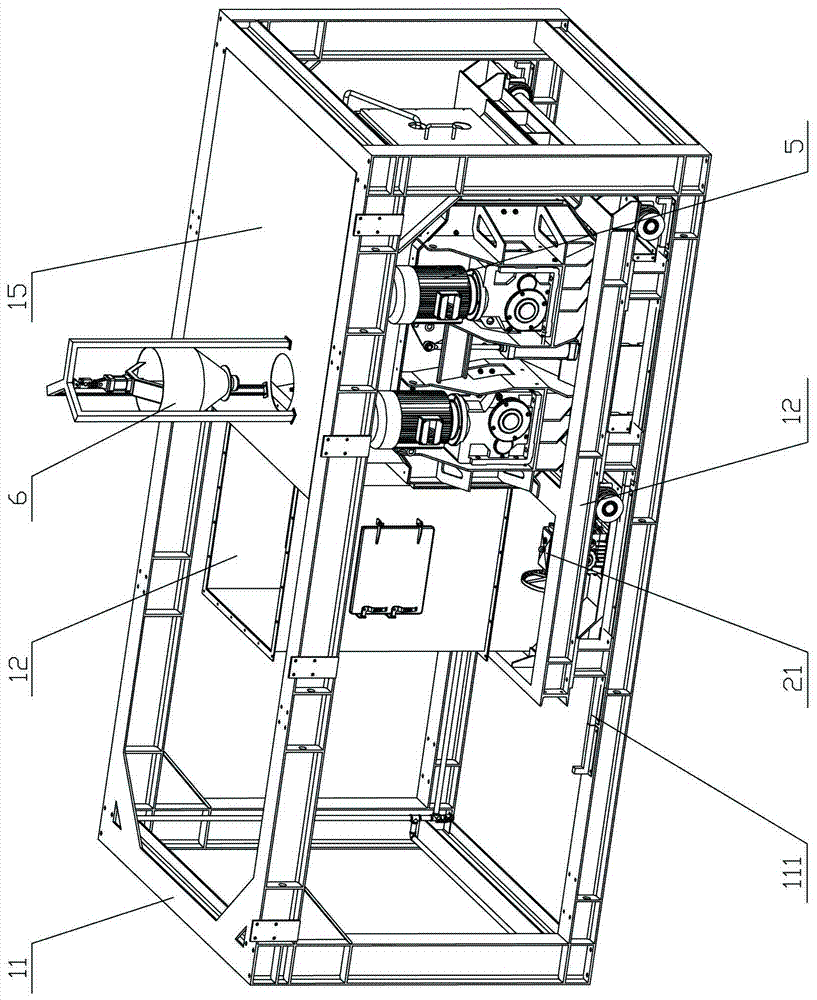

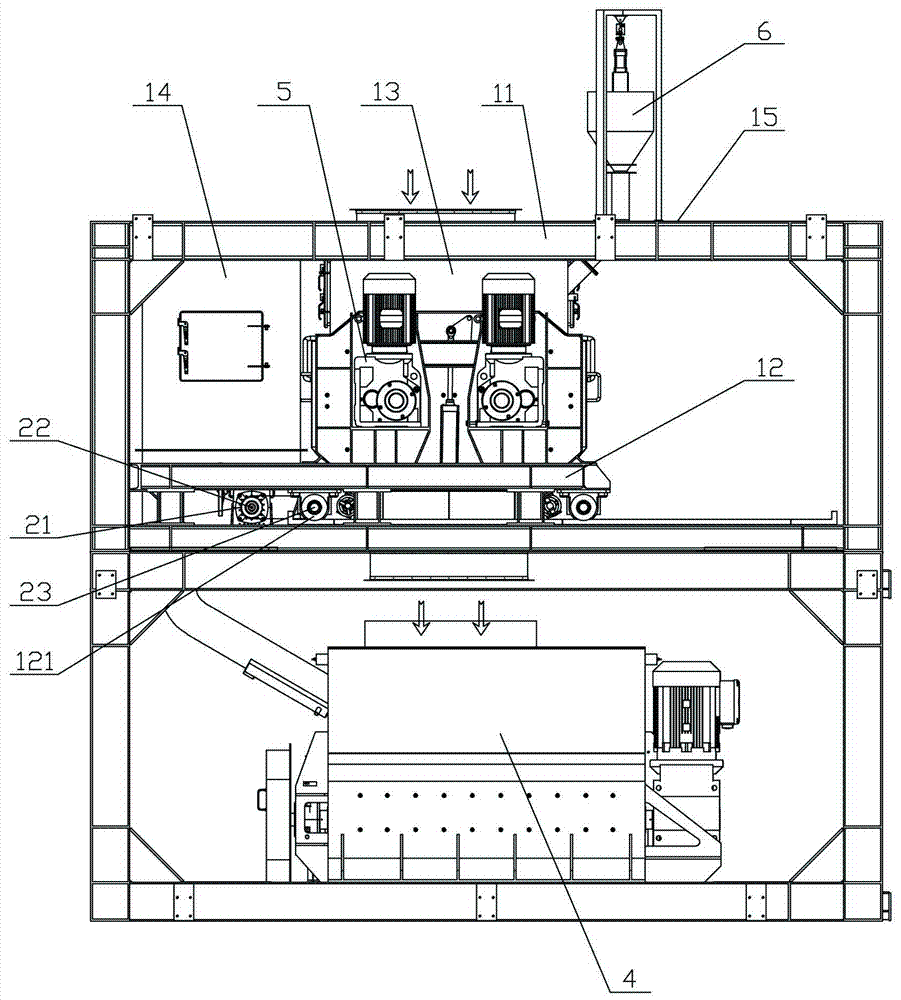

[0029] refer to figure 2 and image 3 , the regenerated material pre-mixing device 10 includes a pre-stirred layer, and the pre-stirred layer includes a stirred layer frame 11, a trolley 12, a first regenerated material chute 13 and a second regenerated material chute 14 arranged on the trolley 12 , the trolley 12 is slidably arranged on the stirring layer frame 11, the first recycled material chute 13 and th...

Embodiment 2

[0033] The difference between this embodiment and the first embodiment lies in the structure of the regenerated material pre-mixing device 10. The regenerated material pre-mixing device in this embodiment includes a stirring layer frame 11, a trolley 12, a first regenerated material chute 13 and a second Two recycled material chutes 14, the trolley 12 is slidably arranged on the stirring layer frame 11, the first recycled material chute 13 is fixed on the trolley 14, the first recycled material chute 13 There is a stirring mechanism 5 inside, and the first regenerated material chute 13 is correspondingly equipped with a regenerant metering hopper. The second recycled material chute 14 is a foldable rectangular frame body, and the second recycled material chute includes a left side wall 141, a right side wall 142, a front side wall 143 and a rear side wall 144. The two ends of the wall 143 and the rear side wall 144 are respectively hinged with the two ends of the left side wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com