Energy-consuming prefabricated pier structure and construction method thereof

A prefabricated and energy-consuming technology, applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve the problems of reducing construction speed, increasing construction difficulty, and large local stress, so as to improve earthquake resistance, improve construction efficiency and Mechanical properties, effect of reduced number of segments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

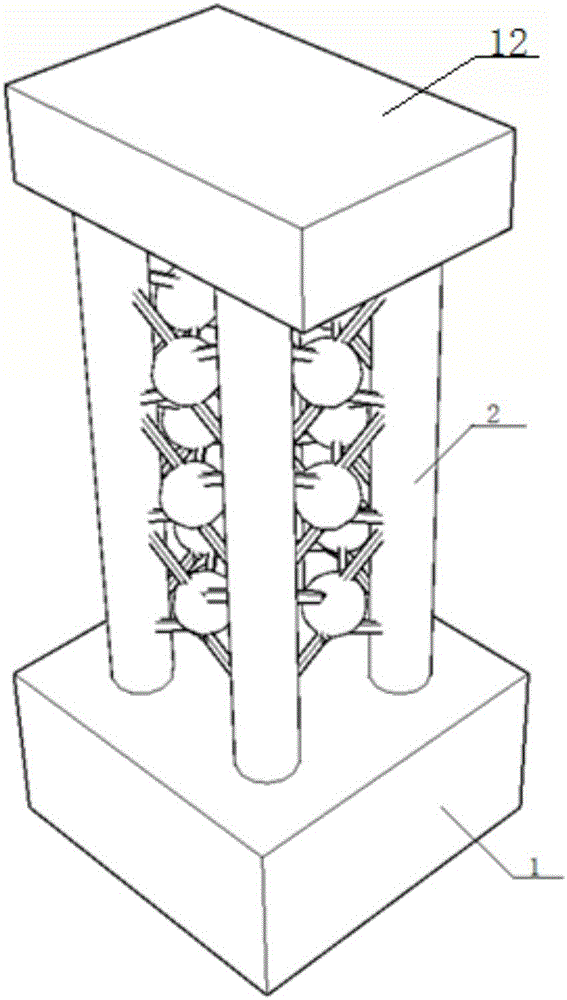

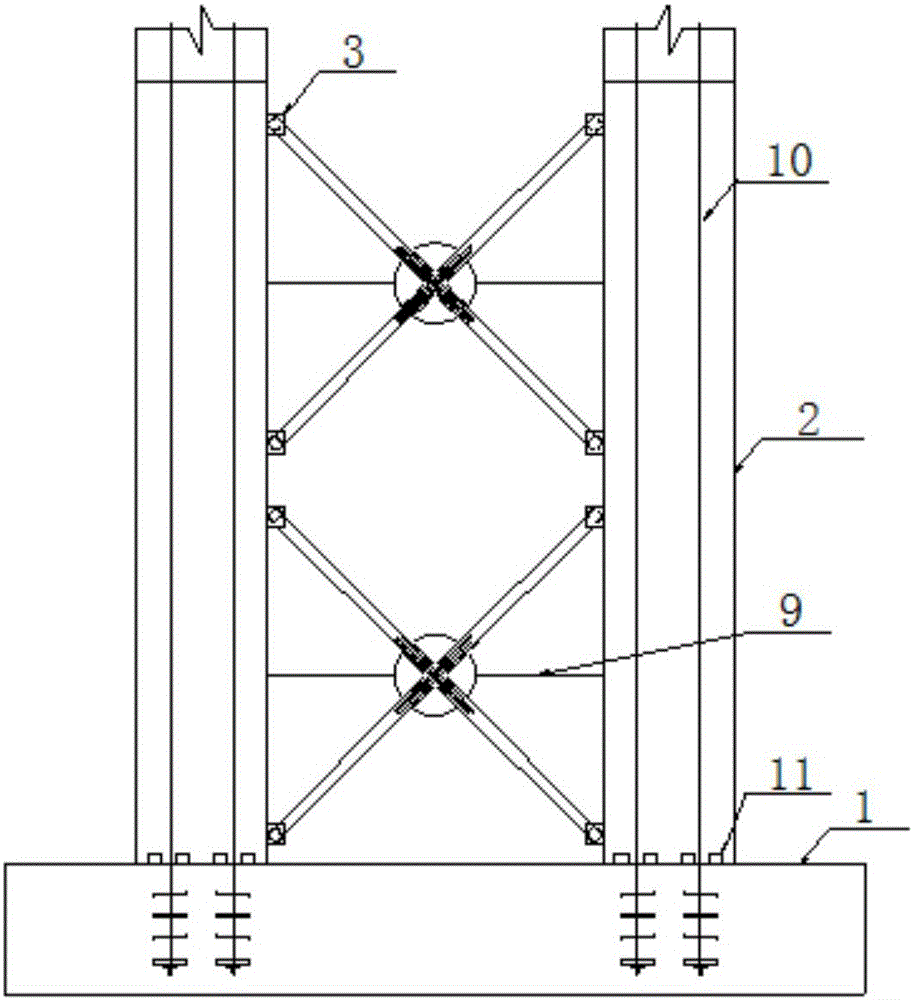

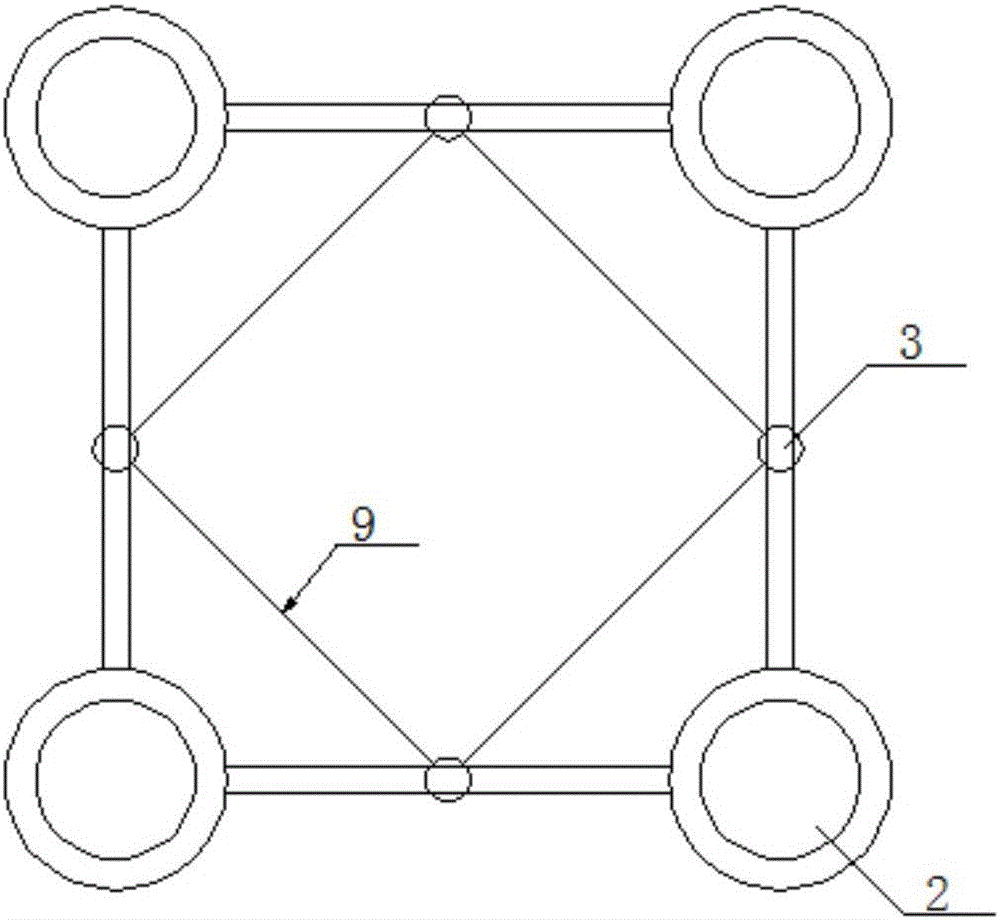

[0030] Such as Figure 1~4 The schematic diagram of the structure of the energy-dissipating assembled pier of the present invention is shown, including a cap 1, a prefabricated assembled pier 2, a joint 3, a damper, a mild steel support 9, a prestressed tendon 10, a shear key 11 and a cover beam 12.

[0031] A plurality of prefabricated assembled piers 2 are vertically arranged on the upper surface of the cap 1, among which four prefabricated assembled piers 2 form a group, replacing one pier in the traditional bridge pier structure, between a group of four prefabricated assembled piers 2 A plurality of dampers are arranged between them, and a cover beam 12 is arranged on the upper surface of the prefabricated assembled pier 2; a pier is divided into a four-legged frame pier composed of four pier columns, which can effectively reduce the section area and increase the size of a single section. Section height, reducing the number of sections for a single pier body.

[0032] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com