Non-disturbance compressive static load test system of foundation base

A compressive static load and test system technology, applied in the test of basic structure, basic structure engineering, construction, etc., can solve the problems of lengthening the length of the rotating platform, invariable spacing distance, small effective component, etc., and reduce the length of the platform. , the effect of reducing insecurity and reducing equipment loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

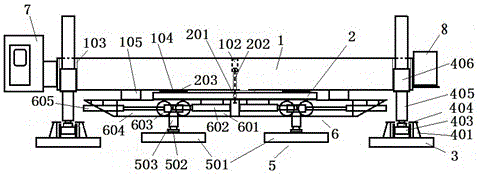

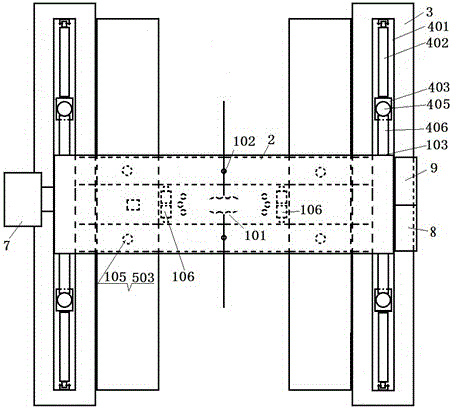

[0028] Such as figure 1 , 2 As shown, the present invention includes a pressure-bearing platform 1, two rotating platforms 2, two outer boats 3, longitudinal movement and lifting mechanism 4, two inner boats 5, lateral movement mechanism 6, cab 7, engine unit 8 and motor hydraulic pump 9,

[0029] A test jack positioning and fixing device 101 is provided under the center of the pressure platform 1, platform through holes 102 are respectively provided on both sides of the center, and outer ship connection ports 103 are provided at the four corners;

[0030] The two rotating platforms 2 are parallel and symmetrically located on the front and rear sides below the middle part of the pressure-bearing platform 1, and each has a perforation 201 in the center, and a connecting shaft 202 corresponding to the through hole 102 of the platform is arranged in the perforation 201, and the rotating platform 2 passes through the connecting shaft 202. Connected with the pressure-bearing plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com