Plastic foam cement composite insulation plate, as well as manufacturing and constructing method thereof

A technology of plastic foam and composite thermal insulation, which is applied in the direction of building roofs and roof coverings, etc., can solve the problems of poor performance of thermal insulation, weak self-protection, poor anti-cracking effect, etc., and achieve waterproof and thermal insulation effects Good, simple operation, less labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

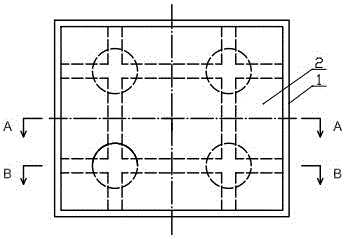

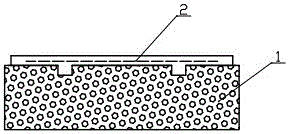

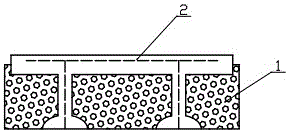

[0029] The plastic foam cement composite thermal insulation board of the present invention comprises a plastic foam thermal insulation bottom mold 1 and a load-bearing concrete structure 2 formed on the plastic foam thermal insulation bottom mold 1 .

[0030] The shape of the plastic foam insulation bottom mold 1 is rectangular or polygonal. For ease of description, a rectangle is taken as an example for drawing description in this embodiment.

[0031] The upper surface of the plastic foam heat preservation bottom mold 1 is provided with several interlaced grooves 3, and vertical channels 4 leading to the lower surface of the plastic foam heat insulation bottom mold are arranged at the junctions of the several interlaced grooves 3 , the aperture of the lower end of the vertical channel increases; the load-bearing concrete structure includes legs 5 poured in the vertical channel, convex ribs 6 formed in the groove and poured on the upper surface of the plastic foam insulation b...

Embodiment 2

[0035] The manufacture method of plastic foam cement composite insulation board of the present invention, carry out according to the following steps:

[0036] Step 1: Make a plastic foam insulation bottom mold, that is, a plastic foam bottom mold; the upper surface of the plastic foam insulation bottom mold is provided with several interlaced grooves, and at the junction of several interlaced grooves, there are Leading to the vertical channel on the lower surface of the plastic foam thermal insulation bottom mold, the aperture of the lower end of the vertical channel increases; the upper surface of the plastic foam thermal insulation bottom mold protrudes upwards to form an enclosure that is convenient for pouring the surface layer;

[0037] Step 2: Concrete is poured from bottom to top on the plastic foam thermal insulation bottom form, so that the vertical channels are gradually filled and a certain thickness is formed on the upper surface of the plastic foam thermal insulati...

Embodiment 3

[0040] The construction method of the plastic foam cement composite thermal insulation board of the present invention includes the plastic foam cement composite thermal insulation board prefabricated in the factory, and the construction method is carried out in the following manner: on the construction level, the plastic foam cement composite thermal insulation board is closely laid side by side , Place gap cover strips in the joints of two adjacent plastic foam cement composite insulation boards, or use concrete or mortar with spiral bars to fill the joints.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com