Quick paving structure of ground tile

A ceramic tile, fast technology, applied in the direction of floor, building structure, construction, etc., can solve the problems of high temperature, difficult construction, low plasticity mortar consumes a lot of manpower, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings.

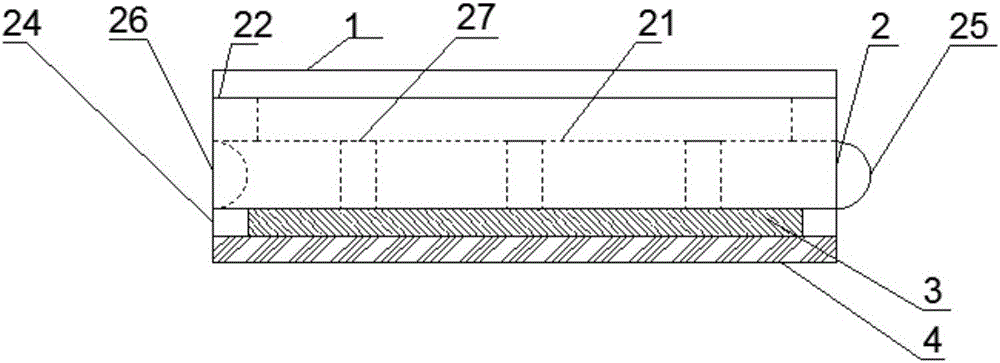

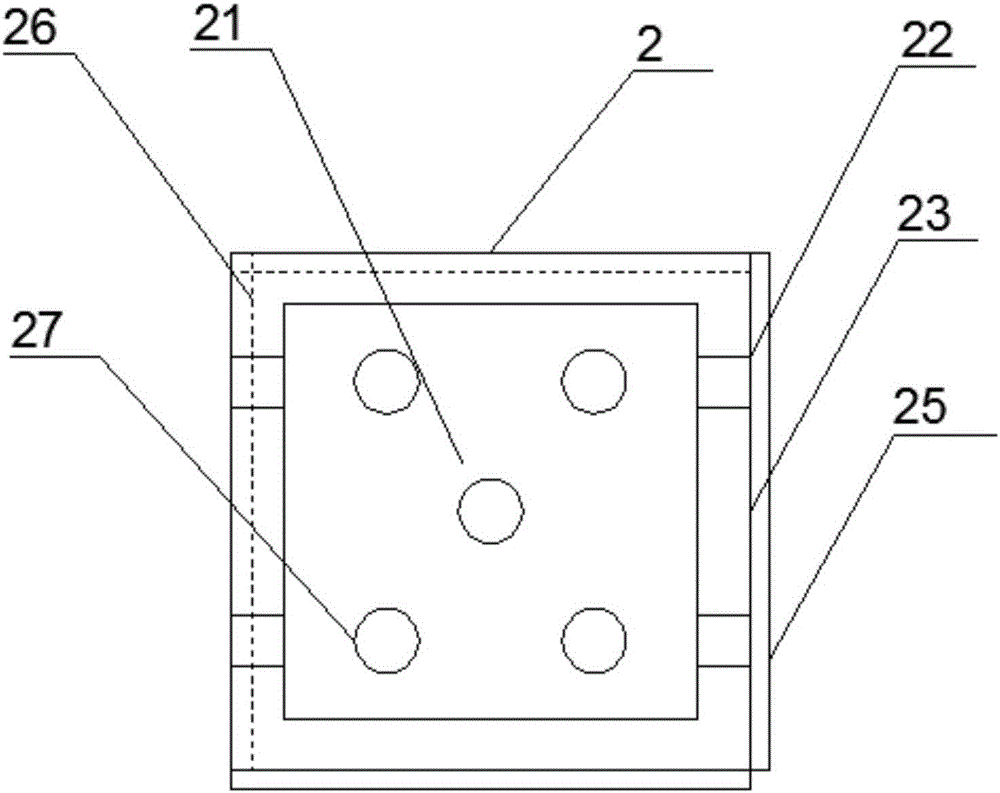

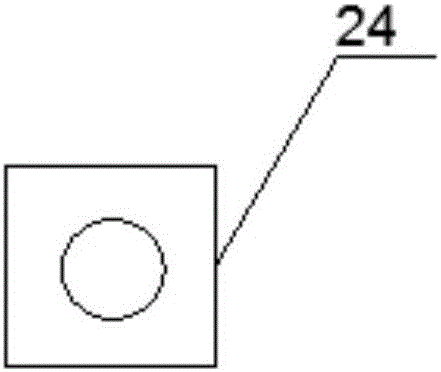

[0032] As shown in the figure, the present invention includes a leveling layer 4, a self-leveling mortar fixed layer 3 is arranged on the leveling layer 4, paving bricks 2 are fixed in the fixing layer 3, and a groove 21 is arranged at the top of the paving brick 2, and the groove 21 is surrounded by vertical walls 23, ceramic tiles 1 are placed on the vertical wall 22, and adhesive is filled in the groove 21. The vertical walls 23 opposite to the two pairs of vertical walls 23 form a group, and the outer surface of one of the vertical walls 23 in each group of vertical walls 23 has a horizontal half. Cylindrical tenon 25, another vertical wall 23 has a semi-cylindrical tenon groove 26 of the same size concave inward, and the bottom surface of the groove 21 of the paving brick 2 has a plurality of through holes 27 communicating with the bottom surface of the paving br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com