Installation tool and method for short supporting legs of bottom head of steel containment vessel of nuclear power station

A technology for a steel containment shell and an installation method, applied in industrial buildings, buildings, building structures, etc., can solve the problems of low efficiency, complicated positioning and installation operations, etc., and achieve the effects of improving safety, saving manpower, and shortening the construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

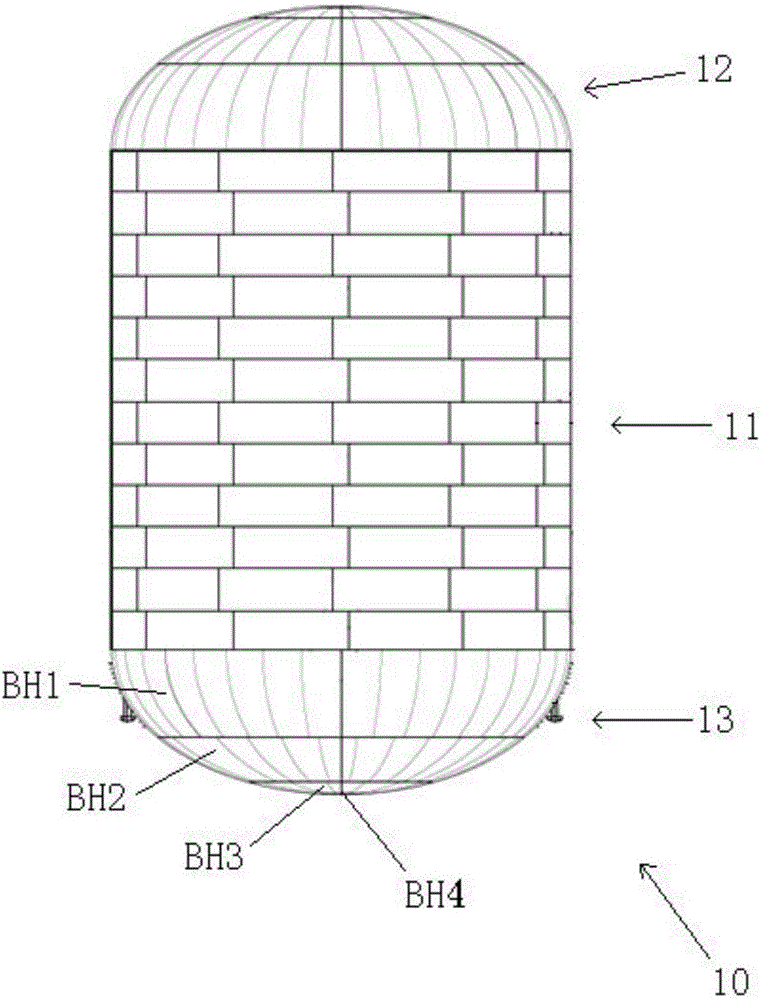

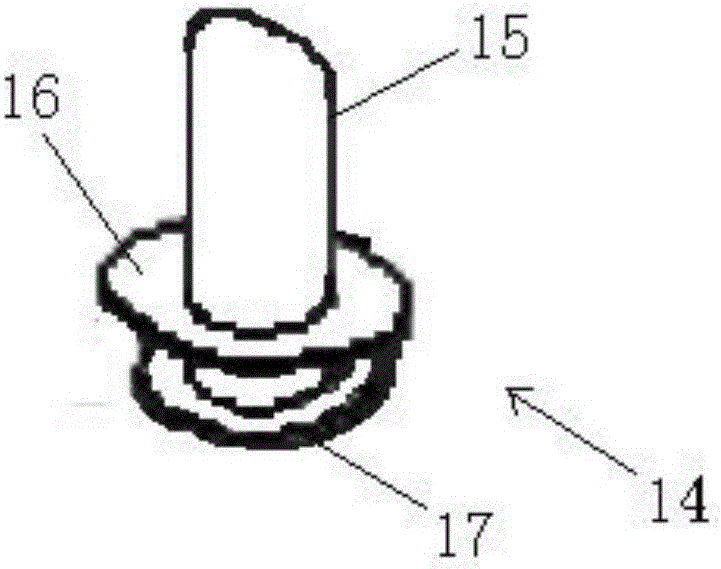

[0033] Such as Figure 3-5 As shown, the installation tooling for the short leg of the steel containment bottom head of the nuclear power plant in this embodiment includes a support frame 20 and a track 25. The support frame 20 is a rectangular frame composed of a number of connecting rods 21. The connecting rods 21 may be H-shaped steel. Inclined supports 22 are provided between the connecting rods 21 to strengthen the structure of the support frame 20. The four corners of the support frame 20 are fixed to the fixing plate 24, and the fixing plate 24 is fixed on the ground of the construction site by expansion bolts, so that the support frame 20 can be firmly fixed to the ground, which improves the safety of operation.

[0034] The track 25 passes through the support frame 20 in a direction perpendicular to the side of the support frame 20. The track 25 is also laid on the ground of the construction site. The track 25 is provided with a transport vehicle 26. The transport vehicle...

Embodiment 2

[0037] Such as Figure 7-8 As shown, the difference between the short leg installation tooling for the steel containment bottom head of the nuclear power plant in this embodiment and the first embodiment is that two fulcrums 23 are symmetrically provided on opposite sides of the support frame 20, and the opposite sides of the support frame 20 The first support column 29, the second support column 28 and the stopper 27 are symmetrically distributed, so that the positioning and installation of the short legs 14 can be performed at the opposite sides of the support frame 20 at the same time, so as to improve work efficiency and shorten the construction period.

[0038] The present invention also proposes a method for installing short legs of the bottom head of the steel containment of a nuclear power plant, which includes the following steps:

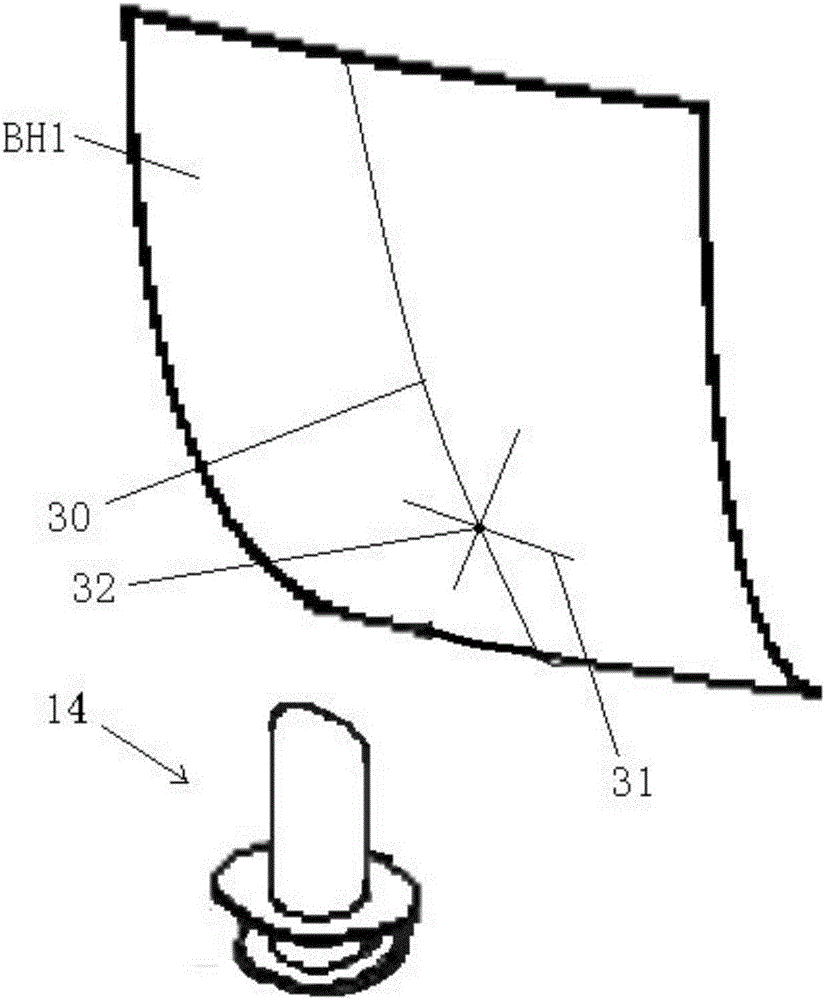

[0039] (1) Determine the centerline reference line of the BH1 board, project the design position of the center reference line on the ground of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com