Mining spraying and dust settling device capable of automatically regulating atomization grain size

An automatic adjustment, spray dust reduction technology, applied in the direction of safety devices, dust prevention, mining equipment, etc., can solve the problems of poor dust reduction efficiency, waste of water resources, etc., and achieve the effects of convenient operation, water saving and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

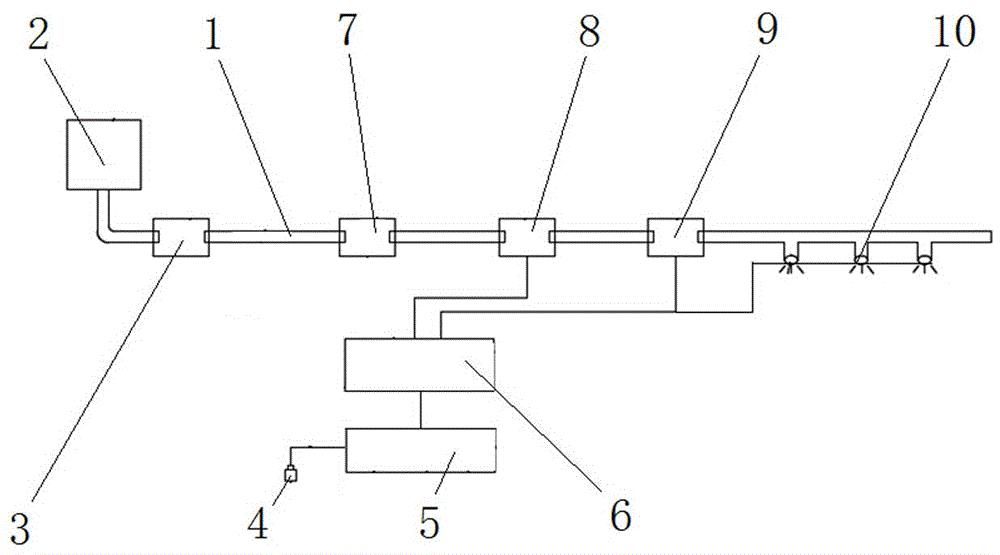

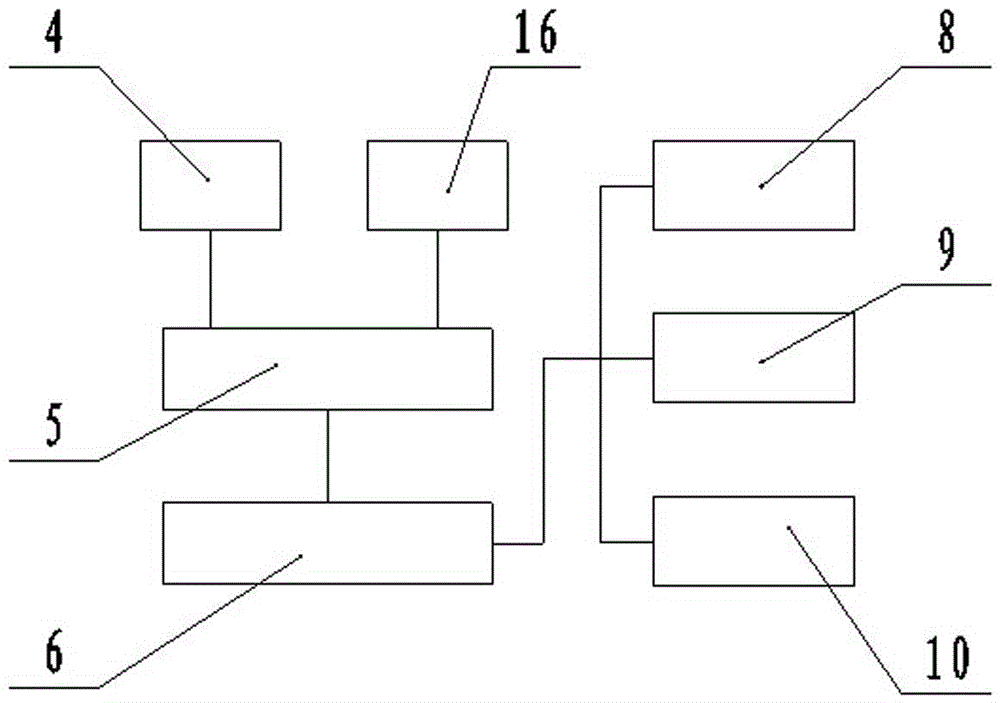

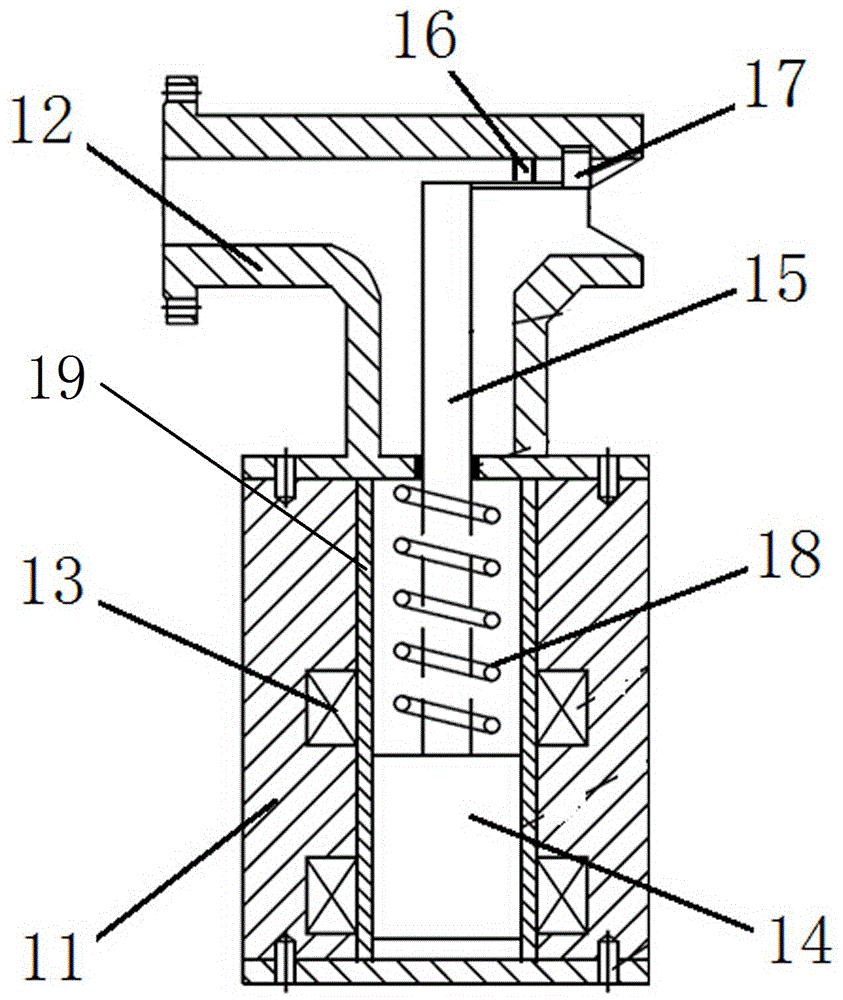

[0013] A spray dust suppression device for mines with automatic adjustment of atomization particle size, including a water pipe 1, a water tank 2 and a water pump 3 on the left side thereof, a dust particle size sensor 4, a central processing unit 5, and an amplifier 6. The right side of the water pipe 1 is connected from the From left to right, there are one-way valve 7, pressure regulating solenoid valve 8, flow regulating solenoid valve 9 and particle size regulating nozzle 10. The particle size regulating nozzle 10 includes a cylinder 11 and a nozzle body 12 located above it and communicating with the cylinder 11. , the cylinder 11 is provided with a metal guide sleeve 19, the metal guide sleeve 19 is provided with an electromagnetic coil 13, the metal guide sleeve 19 is provided with a permanent magnet 14 sliding up and down inside it, and the permanent magnet 14 is connected with a push rod 15, The nozzle body 12 is provided with a pressure sensor 16 and a nozzle valve 17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com