a pump motor

A technology of pump motor and motor working condition, applied in the field of pump motor, can solve the problems of complex structure, transformation, application limitation, etc., and achieve the effect of enriching functions, improving performance, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

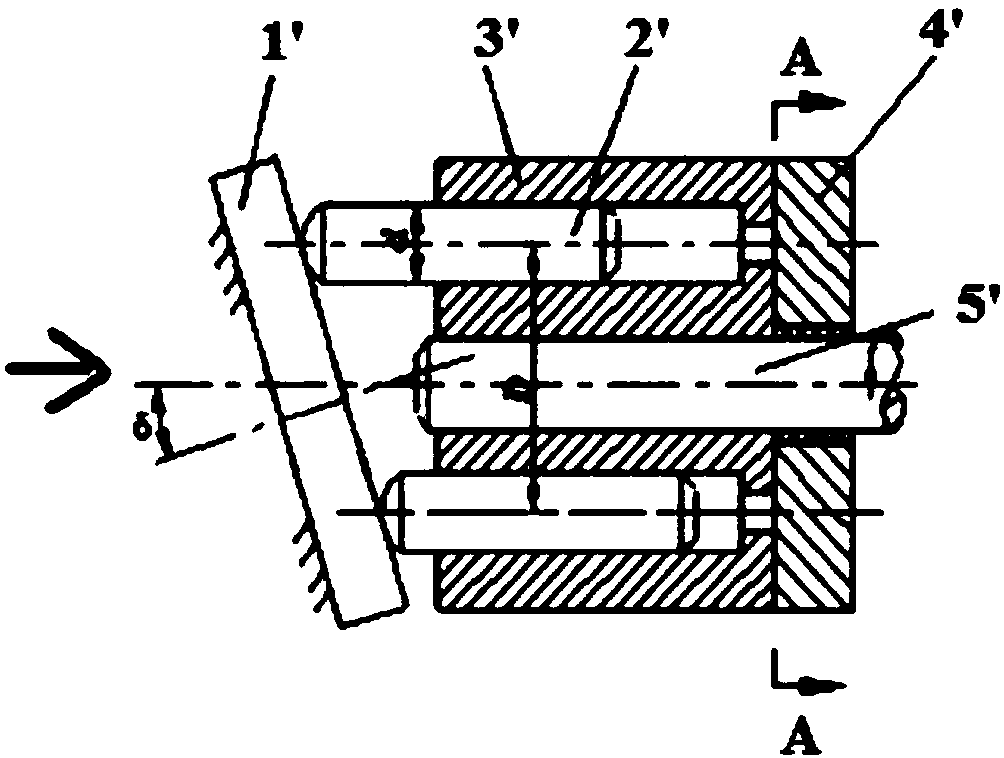

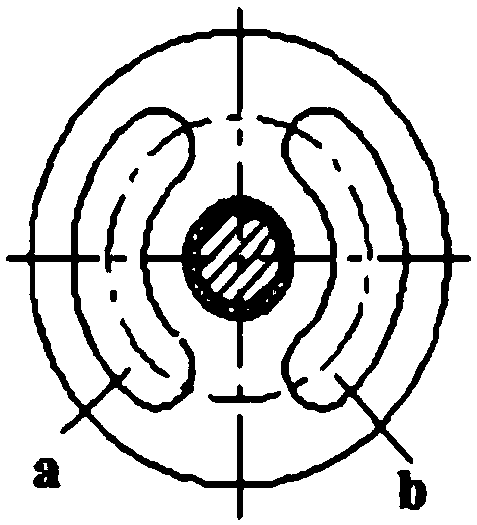

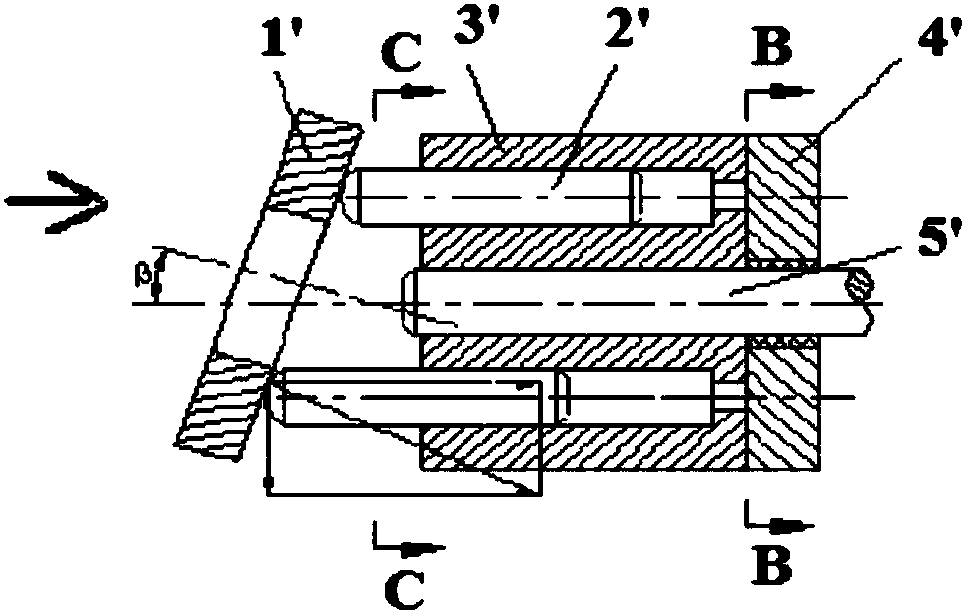

[0050] As an embodiment of the working condition control assembly of the present invention, the working condition control assembly may include a first control mechanism and a second control mechanism, wherein the first control mechanism is arranged between the second working port B and the second liquid control port , and the first oil passage and the second oil passage for connecting the first control mechanism and the second work port B are provided between the first control mechanism and the second work port B; the second control mechanism is arranged on the second oil passage and It can control the on-off of the second oil circuit. When the second control mechanism controls the second oil circuit to be disconnected, the hydraulic oil enters the second liquid control terminal through the first oil circuit and the first control mechanism, and the working condition switching actuator makes the ramp The first end of the disk is on the first side of the zero-angle plane, the pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com