An air intake joint and an internal unloading device for an automobile air compressor

An air compressor and internal unloading technology, which is applied in the field of auto parts, can solve the problems of lowering the temperature of the air compressor, high manufacturing cost, and complicated structural design, and achieve the goal of reducing manufacturing difficulty, reducing manufacturing cost, and shortening response time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to these embodiments.

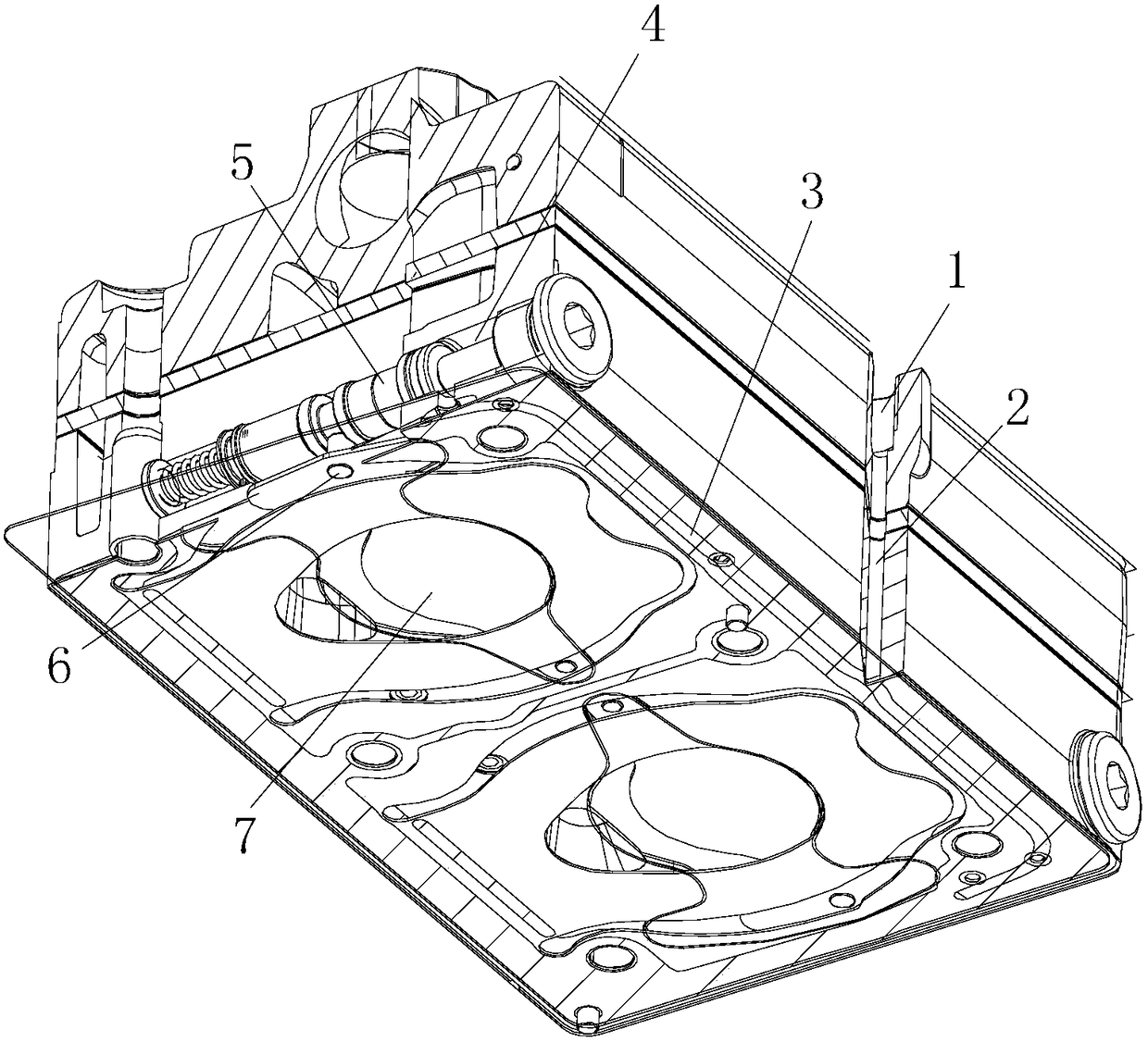

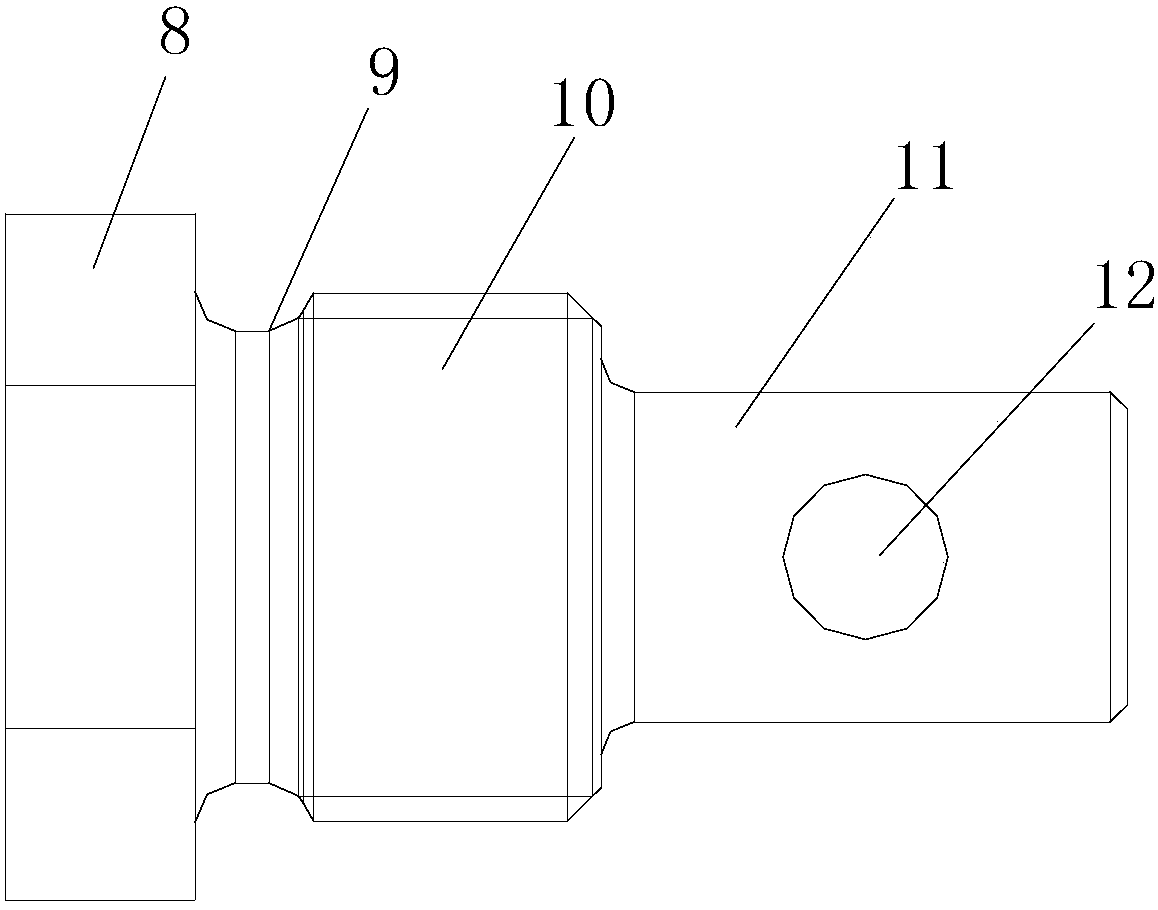

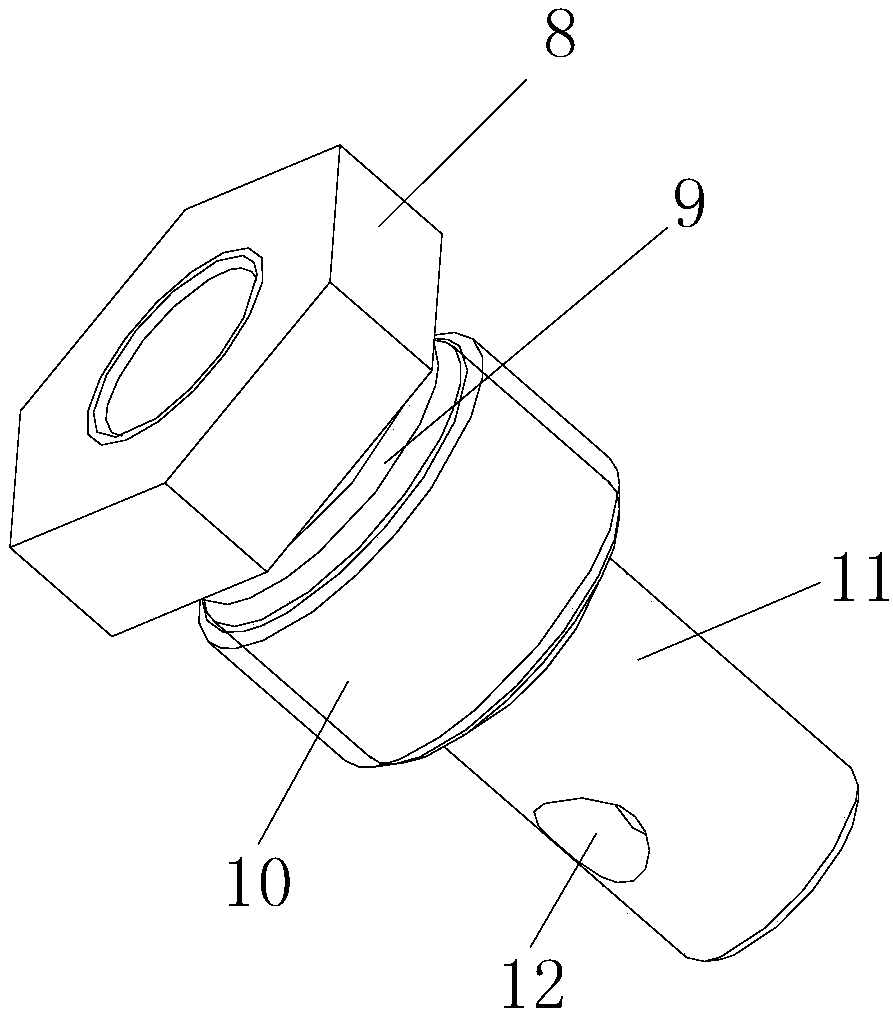

[0027] Such as Figure 1 to Figure 5 As shown, a kind of air inlet joint, comprises integrally formed positioning section and exhaust section 11, and positioning section comprises threaded section 9, and the peripheral circumference of threaded section 9 is provided with external thread, and positioning section also comprises external hexagonal head 8 and The sealing section 10, the outer hexagonal head 8 is fixedly connected with the threaded section 9, one end of the sealing section 10 is fixedly connected with the threaded section 9, and the other end is fixedly connected with the exhaust section 11, and the outer diameter of the sealing section 10 is larger than that of the exhaust section 11. Outer diameter; the exhaust section 11 is provided with two exhaust holes 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com