A kind of gas spray gun for fuel non-reversing regenerative burner

A regenerative and spray gun technology, which is applied to gas fuel burners, burners, combustion methods, etc., can solve the problems of poor flame rigidity and unstable operation of the flame detection electronic eye, and achieves fuel saving, simple structure and good flame rigidity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

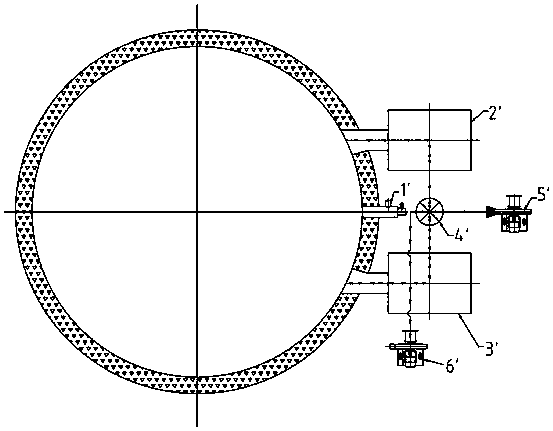

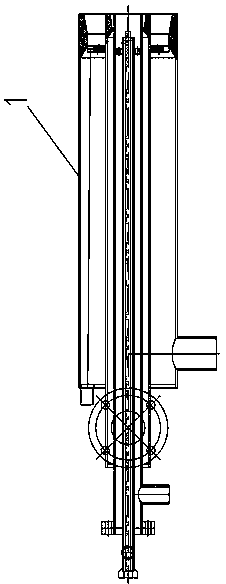

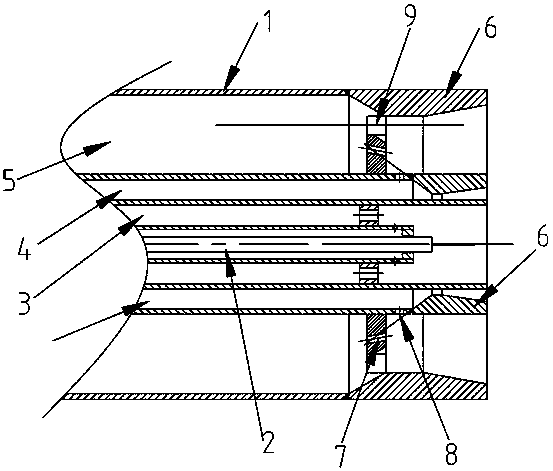

[0016] Please refer to the attached figure 2 And attached image 3 As shown, the present invention is a fuel non-reversing regenerative burner gas spray gun, which includes a spray gun body 1, the spray gun body 1 is the prior art, and will not be repeated here.

[0017] The spray gun body 1 is provided with an ignition gas passage 2 , an ignition combustion air passage 3 , a main gas passage 4 and a combustion air passage 5 sequentially from inside to outside.

[0018] Both the front ends of the main gas passage 4 and the combustion air passage 5 are provided with zoom pipes 6 . The main function of the zoom tube 5 of the main gas channel 4 is to control the gas flow rate and injection angle, the inlet angle is 60-80 degrees, the outlet angle is 10-20 degrees, and the gas outlet flow rate is controlled to be 60-100 meters per Second. The inlet angle of the zoom pipe 6 of the combustion-supporting air channel 5 is 40-60 degrees, and the outlet angle is 5-20 degrees, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com